Material processing system based on novel shuttle vehicles

A technology for processing systems and shuttle vehicles, which is applied in the direction of motor vehicles, railway vehicles, conveyor objects, etc., can solve the problems of many failure points and high cost of the whole system, and meet the requirements of simplified design, increased flexibility, and reduced installation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

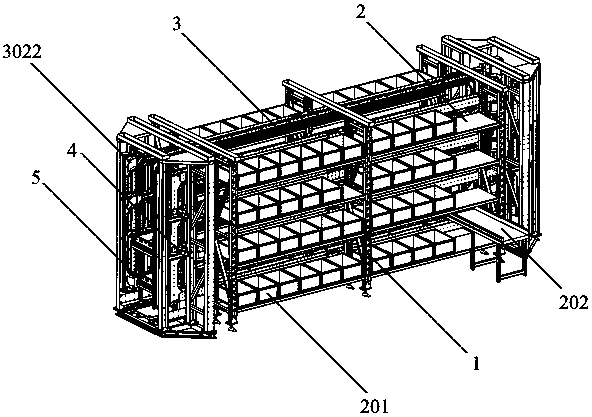

[0034] Example: as attached figure 1 And attached Figure 9 As shown, a material handling system based on a new shuttle car, including:

[0035] Shelf 1 is located on both sides of the system, and the interior of the shelf is divided into several rows and columns by structure; each row and each column is respectively equipped with a material handling position 2, and a turnover container 201 can be placed in the material handling position, and the material handling position can be integrated with automation The conveying mechanism 202 is docked; the material processing position is set on the shelf.

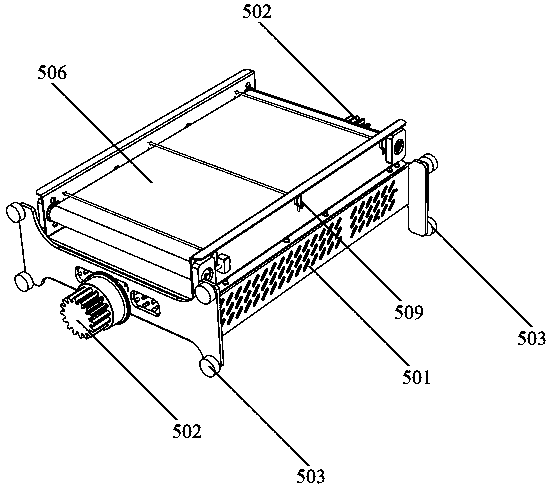

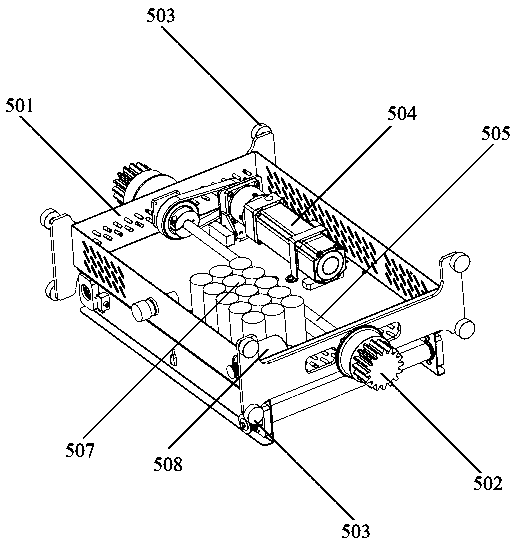

[0036] as attached Figure 4 And attached Image 6 As shown, the guide rail system 3, including the main guide rail 301, the auxiliary guide rail 302 and the charging guide rail 303, is connected to the shelf. The guide rail system matches the shelf structure into several rows and several columns, and a shutter mechanism 4 is provided at the intersection of the row and column gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com