Pressure sensor having overpressure protection with reduced output error

A pressure sensor and sensor technology, applied in the direction of measuring fluid pressure through electromagnetic components, elastic deformation meter type fluid pressure measurement, measuring fluid pressure, etc., can solve the problems of sensor damage, unreliability, and expensive, etc., and achieve output error reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

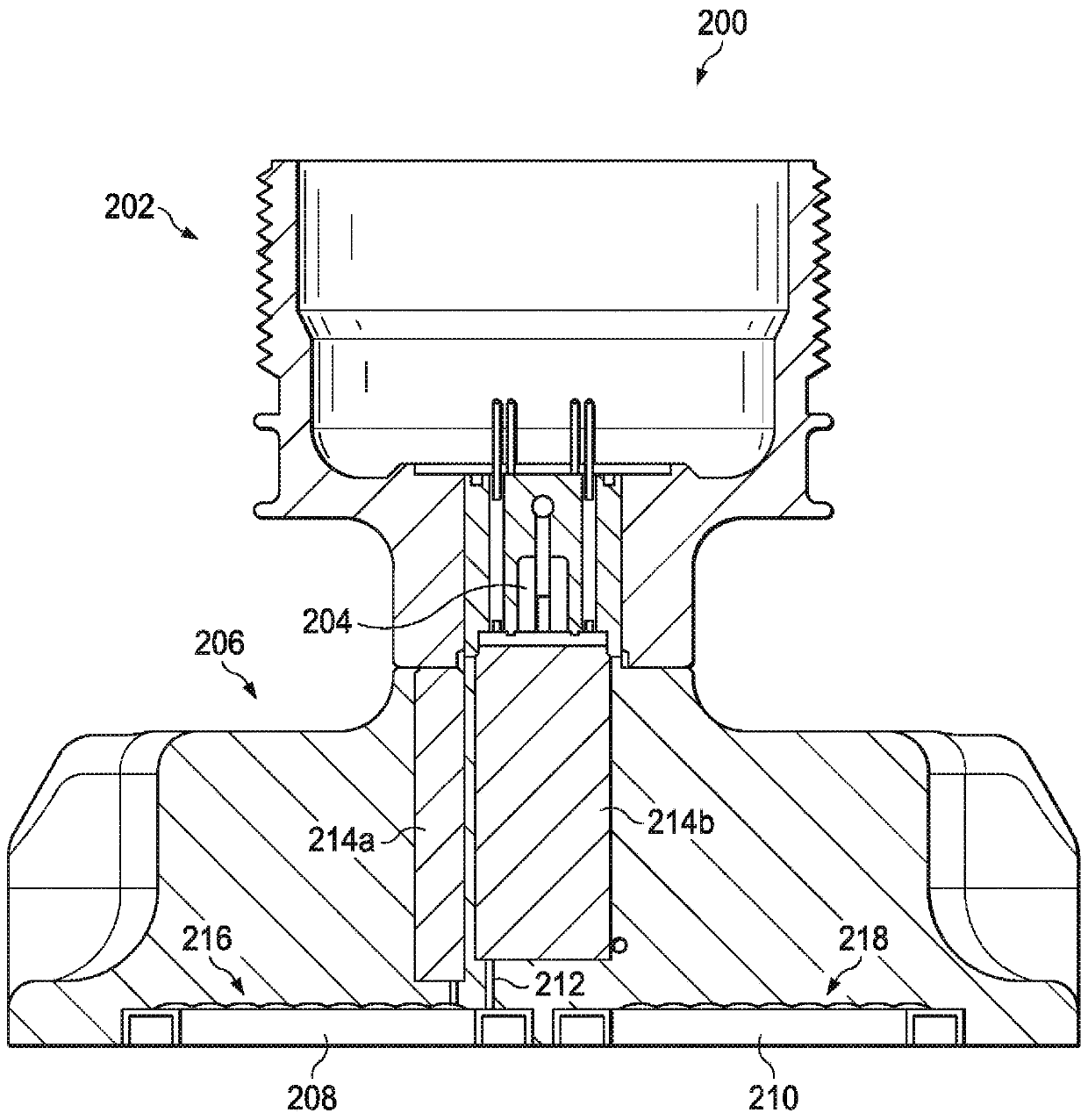

[0024] Figure 1 to Figure 8 (discussed below) and the various embodiments used to describe the principles of the invention in this patent document are by way of illustration only and should not be construed as limiting the scope of the invention in any way. Those skilled in the art will understand that the principles of the invention may be implemented in any type of suitably arranged device or system.

[0025] figure 1 An exemplary industrial process control and automation system 100 according to the present disclosure is shown. Such as figure 1 As shown, system 100 includes various components that facilitate the production or processing of at least one product or other material. For example, system 100 may be used to facilitate control of components in one or more industrial plants. Each plant represents one or more processing facilities (or one or more portions thereof), such as one or more manufacturing facilities for producing at least one product or other material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com