A spray cooling device combining steam chamber and composite microstructure

A composite microstructure and spray cooling technology, which is used in cooling/ventilation/heating transformation, electrical equipment structural parts, electrical components, etc. Complex heat exchange technology and other problems, to achieve the effect of improving the stretchability of the liquid film, improving the heat dissipation effect, and reducing the thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the accompanying drawings.

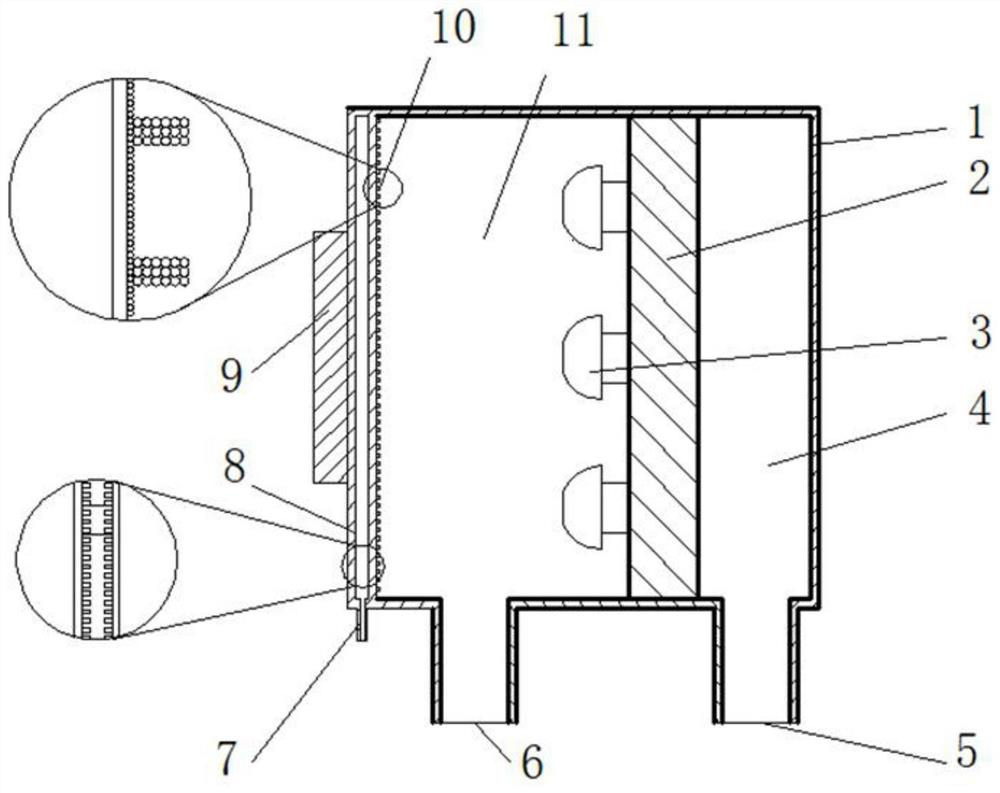

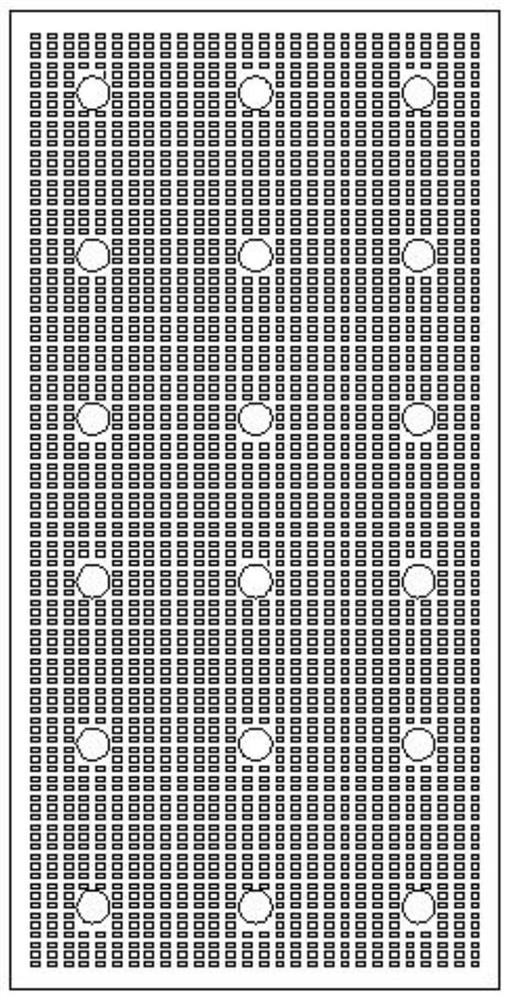

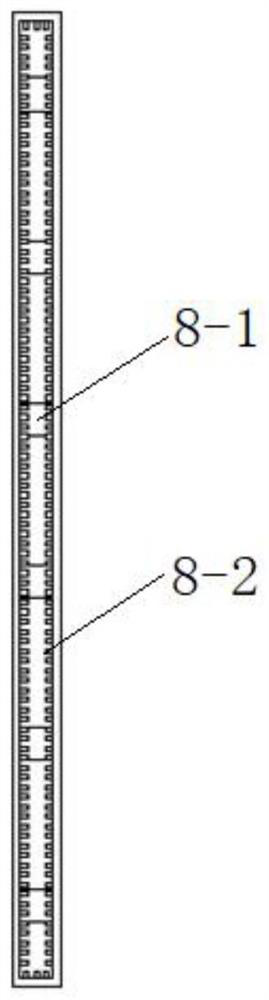

[0025] combine figure 1 , a spray cooling device combining a steam chamber and a composite microstructure, comprising a spray chamber 1, a spray chamber liquid inlet pipe 5, a spray chamber liquid outlet pipe 6, and a steam chamber 8. The spray chamber body 1 and the steam chamber 8 Set as one piece, the spray chamber 1 includes an orifice plate 2 , an array nozzle 3 and a composite microstructure 10 located therein, and the orifice plate 2 divides the spray chamber 1 into a buffer chamber 4 and a spray chamber 11 , the function of the buffer chamber 4 is to provide a uniform liquid inlet pressure to the nozzles 3 arranged in the array, the liquid inlet pipe 5 of the spray chamber is communicated with the buffer chamber 4, the outlet pipe 6 of the spray chamber is communicated with the spray chamber 11, The spray chamber body, the spray chamber liquid inlet pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com