Beam near-field intensity distribution self-homogenizing high-energy laser device

A high-energy laser and intensity distribution technology, applied in the field of lasers, can solve problems such as inability to improve laser efficiency and beam quality, limit beam homogenization effect, increase system complexity, etc., to avoid the accumulation of uneven gain effects and have good adaptability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

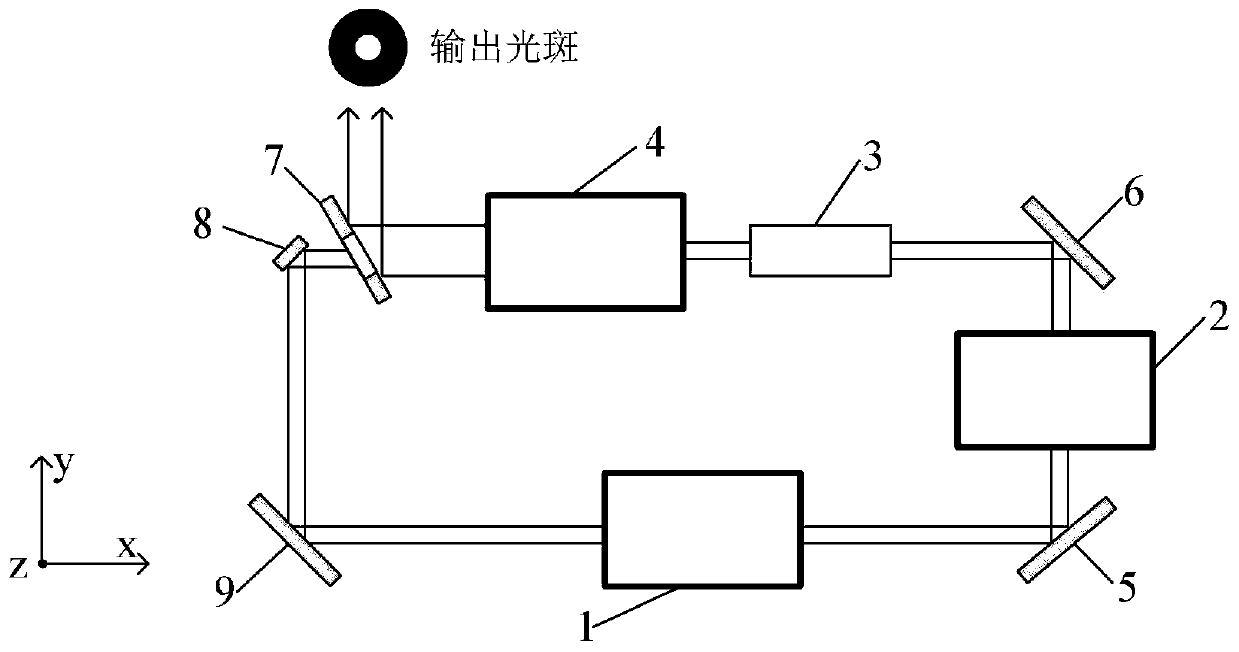

[0046] Such as Figure 1-4 A self-homogenizing high-energy laser with near-field intensity distribution of the beam shown includes a beam rotation system 1, and the beam rotation system 1 includes at least 5 mirrors with an odd number;

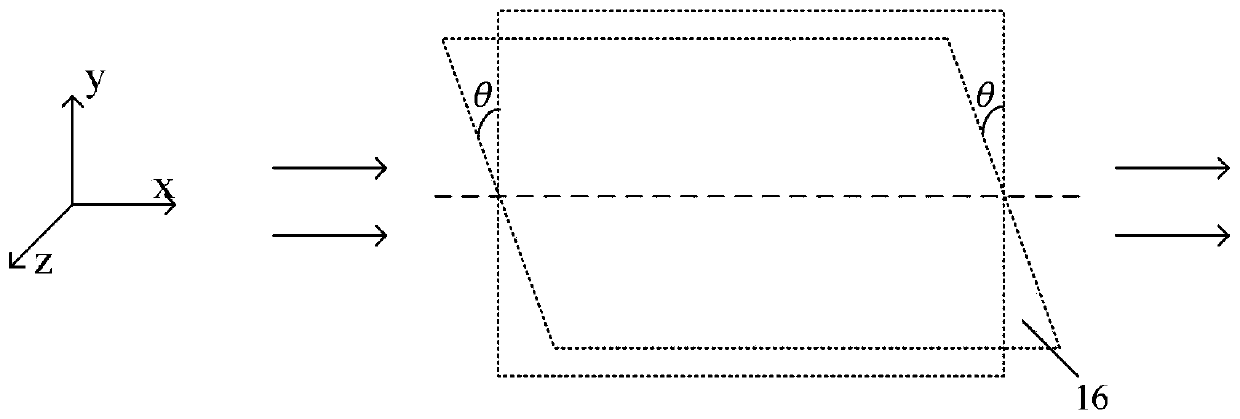

[0047] In the present embodiment, n=5, respectively the first reflector 11, the second reflector 12, the third reflector 13, the fourth reflector 14 and the fifth reflector 15, all reflectors are in the same optical main In plane 16;

[0048] The connecting line between the centers of the first reflector 11 and the fifth reflector 15 constitutes the rotation axis of the beam rotation system 1;

[0049] During the rotation process, the relative positions of the second reflector 12, the third reflector 13, the fourth reflector 14, the first reflector 11 and the fifth reflector 15 remain fixed, and all rotate around the axis of rotation. The angle is set to θ, θ is determined according to the gain characteristics of the specific gain medium of ...

Embodiment 2

[0071] This embodiment provides a self-homogenizing high-energy laser with near-field intensity distribution of the beam. The difference from Embodiment 1 is that the number of mirrors in the beam rotation system is n=7, 9, 11... as required, and the use process and principle are the same as Embodiment 1 is similar.

Embodiment 3

[0073] This embodiment provides a self-homogenizing high-energy laser with near-field intensity distribution of the beam. The difference from Embodiment 1 is that the number of resonator mirrors is selected according to needs to form a regular polygonal ring resonator. The use process and principle are the same as Embodiment 1. similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com