Truss-type steam-liquid phase change heat-transferring device and assembling and welding method thereof

A truss-type, vapor-liquid technology, applied in the field of phase change heat transfer, can solve problems such as waste of resources, and achieve the effects of reducing equipment weight, strong structural adaptability, and saving active temperature control power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

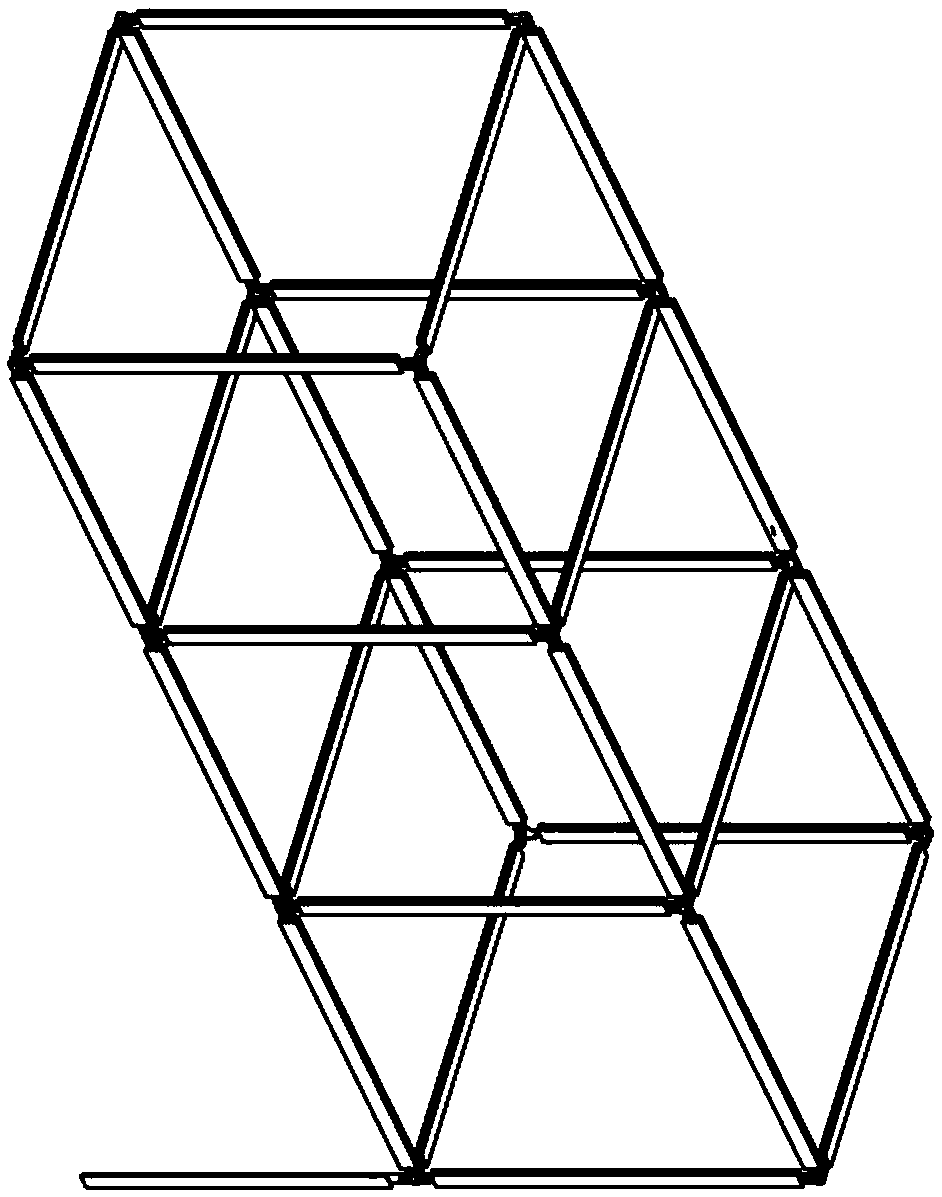

[0029] The invention relates to the technical field of phase change heat transfer, and discloses a truss type vapor-liquid phase change heat transfer device and its assembly and welding method. End caps, filling end caps and filling tubes. The shape of the connector includes: T-type, L-type, cross-type, special-type. A truss structure can be formed between any two tube shells with capillary cores inside, and the capillary cores and steam channels between any two tube shells are connected to each other through the capillary cores and steam channels in the joints. In order to realize the circulation of vapor-liquid phase change heat transfer working medium in the whole truss d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com