Modeling method of bed body fluid-heat-solid coupling finite element thermal characteristic analysis model

A technology of analysis model and modeling method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low accuracy of heat transfer coefficient, large error, and failure to meet the thermal design analysis of the bed, and achieve construction The effect of clear thinking, high accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

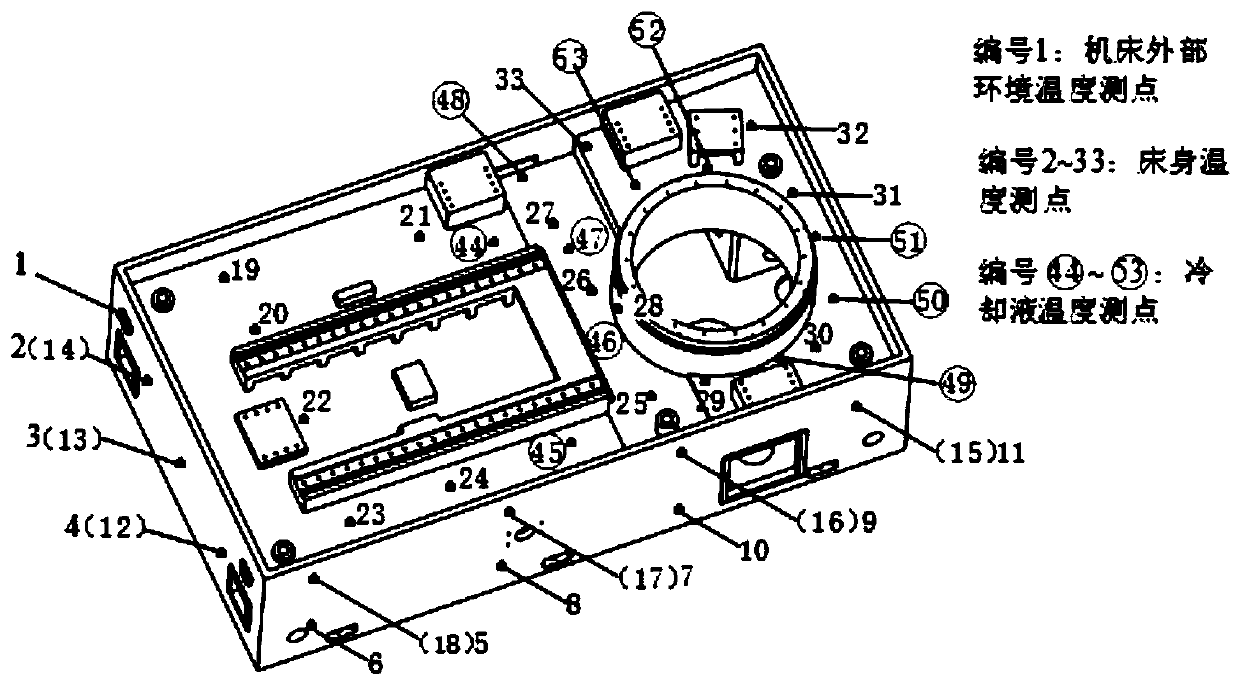

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] refer to figure 1 , a modeling method for bed flow-thermal-solid coupling finite element thermal characteristic analysis model, including the following steps:

[0034] 1) Combining the theoretical calculation and the surveying and mapping results of the actual coolant coverage under the grinding process, the real geometric model of the coolant is established on the basis of the geometric model of the bed, and the specific steps are as follows:

[0035] 1.1) In the 3D modeling software (Pro / E, Solidworks, etc.), establish the geometric model of the bed according to the actual size of the bed in order to improve the analysis efficiency; if there is a bed model, it needs to be simplified. The basic principles of simplification are: Delete shape structures and accessories that have little influence on thermal characteristic analysis and structural static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com