Soil retaining structure suitable for power building built on soft geology

A soil retaining structure and electric power technology, which is applied to buildings, underwater structures, infrastructure engineering, etc., can solve the problems of uncontrollable internal quality, long construction period, and prone to collapse, so as to achieve stable and controllable internal quality, cycle time Short, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

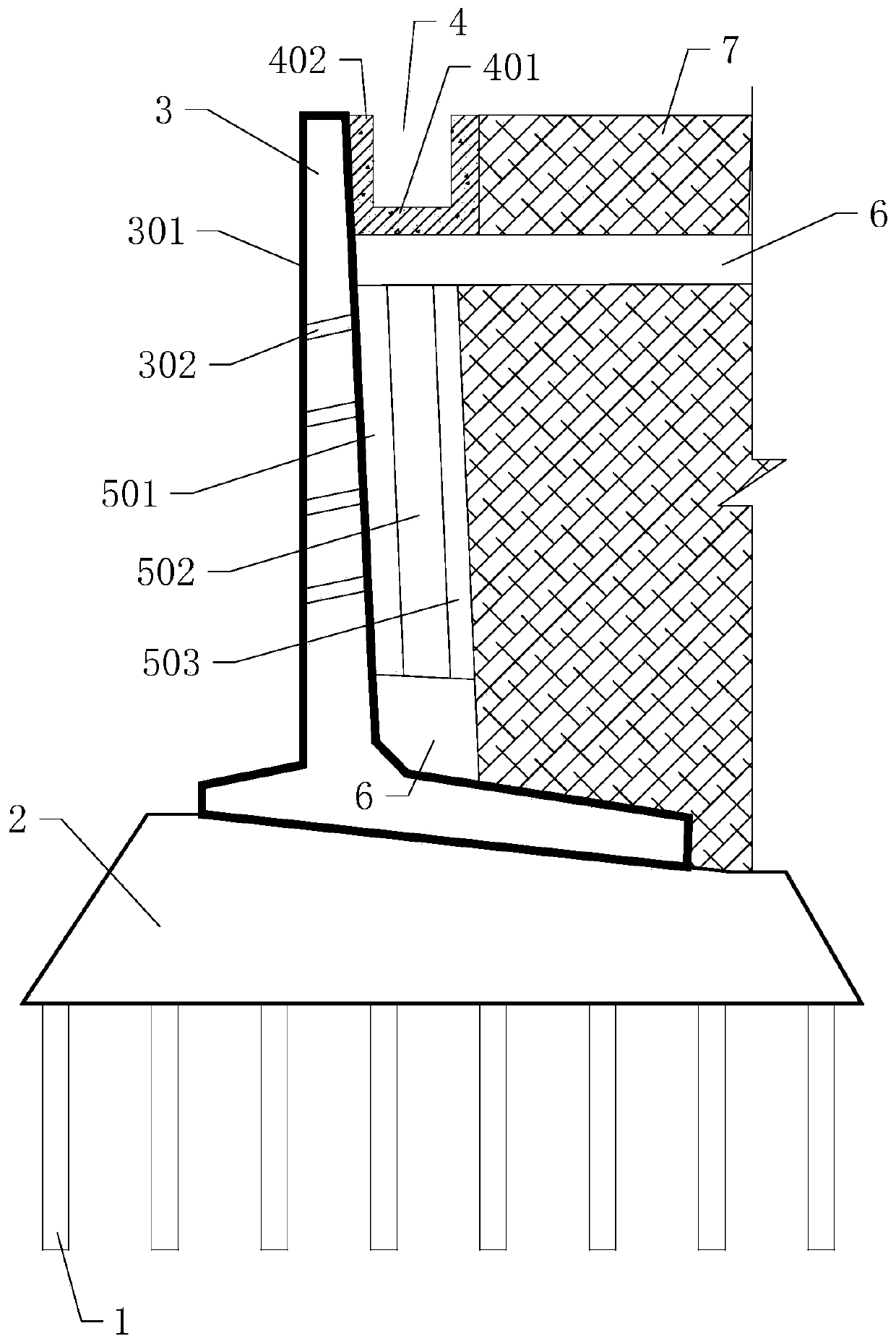

[0032] see figure 1 , this embodiment provides a soil retaining structure suitable for power buildings built on soft ground, used to cover backfill sandy soil 7 on the side of the power building, including a pile foundation reinforcement structure 1, a graded sandstone cushion layer 2 and retaining wall body 3. The graded sand cushion layer 2 is located above the pile foundation reinforcement structure 1 and gradually becomes thicker toward the power building; the retaining wall main body 3 is composed of cement and steel bars, and is located Above the stone mat cushion 2; the side of the retaining wall main body 3 close to the power building is a vertical surface structure 301 whose thickness gradually increases from top to bottom. Preferably, the power building can be a substation.

[0033] It can be understood that the pile foundation reinforcement structure 1 is set at the bottom as a supporting foundation to reduce the requirements of the main body of the retaining wall...

Embodiment 2

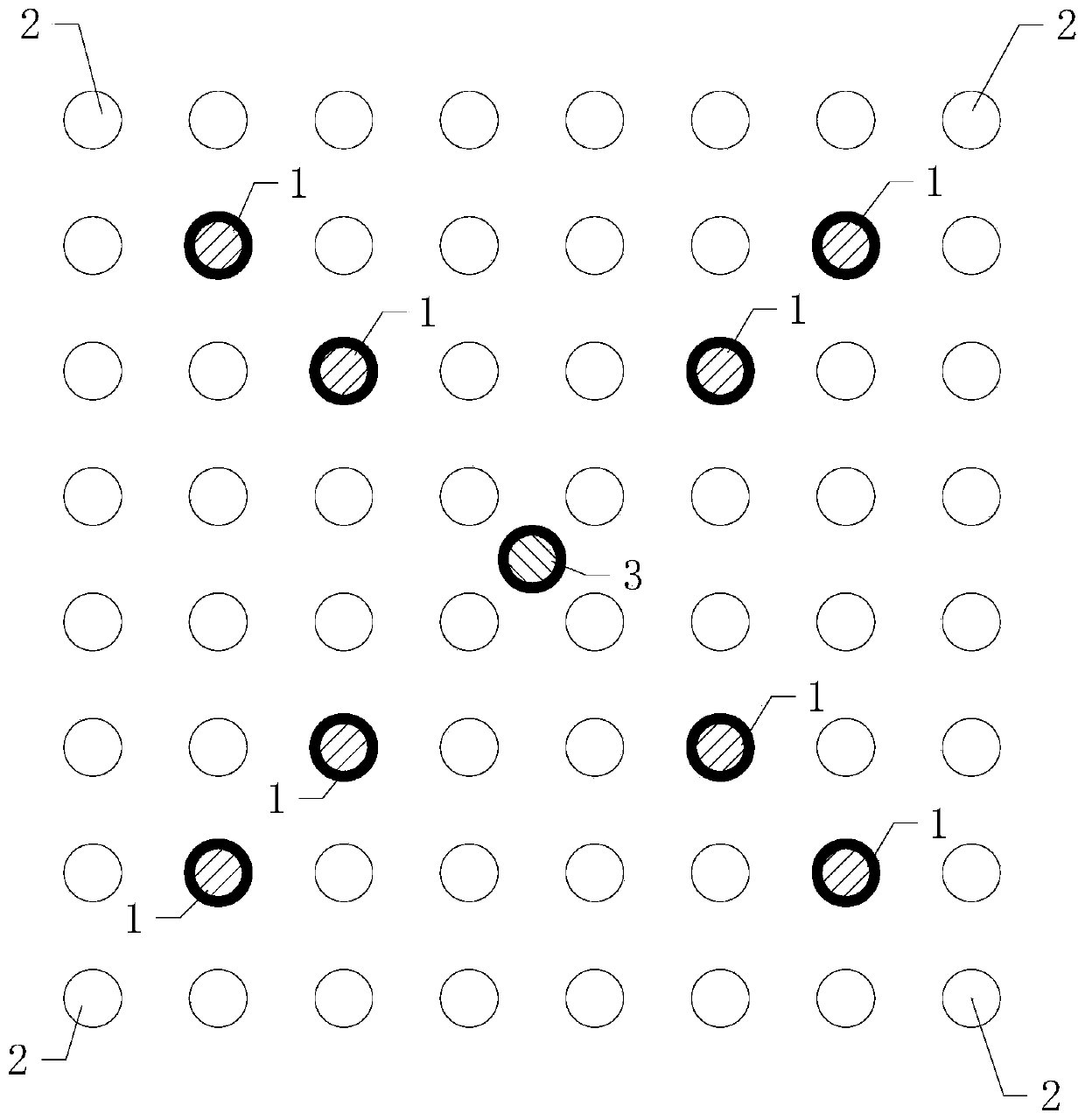

[0046] see figure 2 , this embodiment provides a pile foundation reinforcement structure suitable for Embodiment 1, including several pile foundation stations arranged in a square array, part or all of which are located on the pile foundation stations on the diagonal of the square array Each erection is provided with a peripheral jet grouting pile 1, and each of the remaining pile foundation stations is provided with a wooden pile 2.

[0047] It can be understood that the combination of the wooden pile 2 and the rotary grouting pile can not only ensure the stability of the foundation, but also reduce the economic cost.

[0048] Preferably, a central jet grouting pile 3 is provided at the intersection of two diagonal lines of the square array, and the number of the peripheral jet grouting piles 1 is an integer multiple of four. Further, every four peripheral jet grouting piles 1 can form four vertices of a regular quadrilateral. It can be understood that the regular quadrila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com