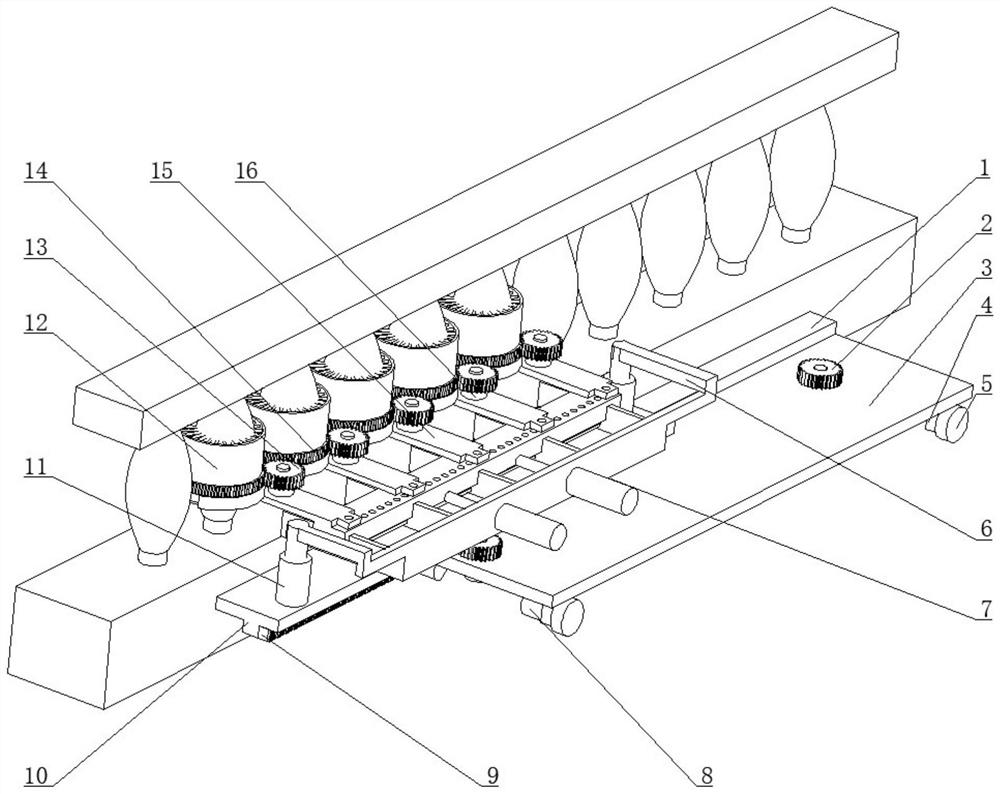

A bridge guardrail multi-angle cleaning machine

A multi-angle cleaning machine technology, applied in cleaning methods, road surface cleaning, construction, etc., can solve the problems of cleaning dead corners, affecting traffic, and unsafe manual cleaning of guardrails, etc., and achieves the effect of less space and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

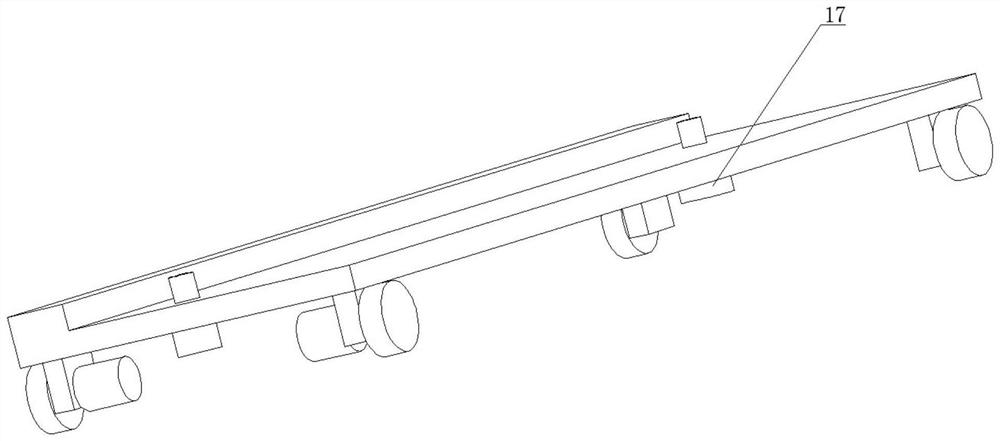

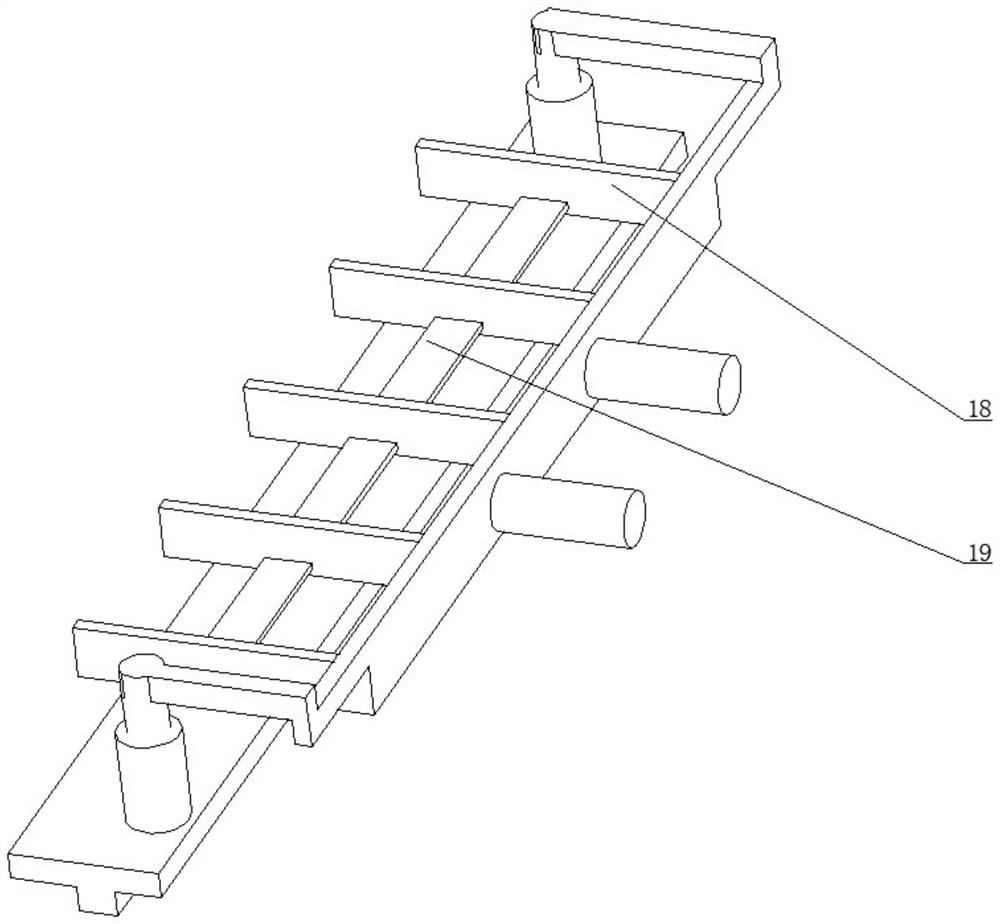

[0055] Embodiment 1: It is possible to clean one end of the bridge. Manually control the retraction of the electric push rod 17, and manually control the motor 18 to advance to the next position for automatic cleaning. Manually control the electric push rod 2 11 to drive the U-shaped rod 6 to move upwards, and then move in the opposite direction. Through related components, the cleaning mechanism is driven to move up and down reciprocatingly. At the same time, the motor 2 16 is turned on, and the motor 2 16 drives the gear 13 rotates, so that motor 2 16 controls one end of the half ring gear 14 to contact with gear 2 13 until the other end of the half ring gear 14 contacts with gear 2 13, then turn on motor 2 16 in reverse to make gear 2 13 reverse again With the same number of turns, the hairbrush 24 moves up and down while reciprocating rotation through related components, and the hairbrush 24 wipes the bridge guardrail, realizing semi-automatic cleaning.

Embodiment 2

[0056] Embodiment 2: The controller controls the motor 8 and the motor 17 to cooperate to keep the cleaning mechanism still relative to the railing. The controller records the moving distance of the electric push rod 1 7, the movement of the electric push rod 2 11, and the rotation of the motor 2 16 And motor three 17 rotation situations, and control corresponding electric push rod one 7, electric push rod two 11, motor two 16 and motor three 17 in order. Make the electric push rod one 7 reciprocatingly move back and forth, and the electric push rod two 11 reciprocate up and down to realize the reciprocating up and down movement and forward and backward movement of the cleaning mechanism. The controller controls the rotation of the motor two 16, thereby realizing the reciprocating rotation of the brush 24, and The brush 24 reciprocates and moves up and down while reciprocating rotation, and the hairbrush 24 wipes the bridge guardrail, and realizes fully automatic at last.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com