Preparation method of bepotastine besilate

A technology of bepotastine benzenesulfonate and hydrochloric acid is applied in the preparation of sulfonates, chemical instruments and methods, feeding devices, etc., and can solve problems such as difficulty in the method of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

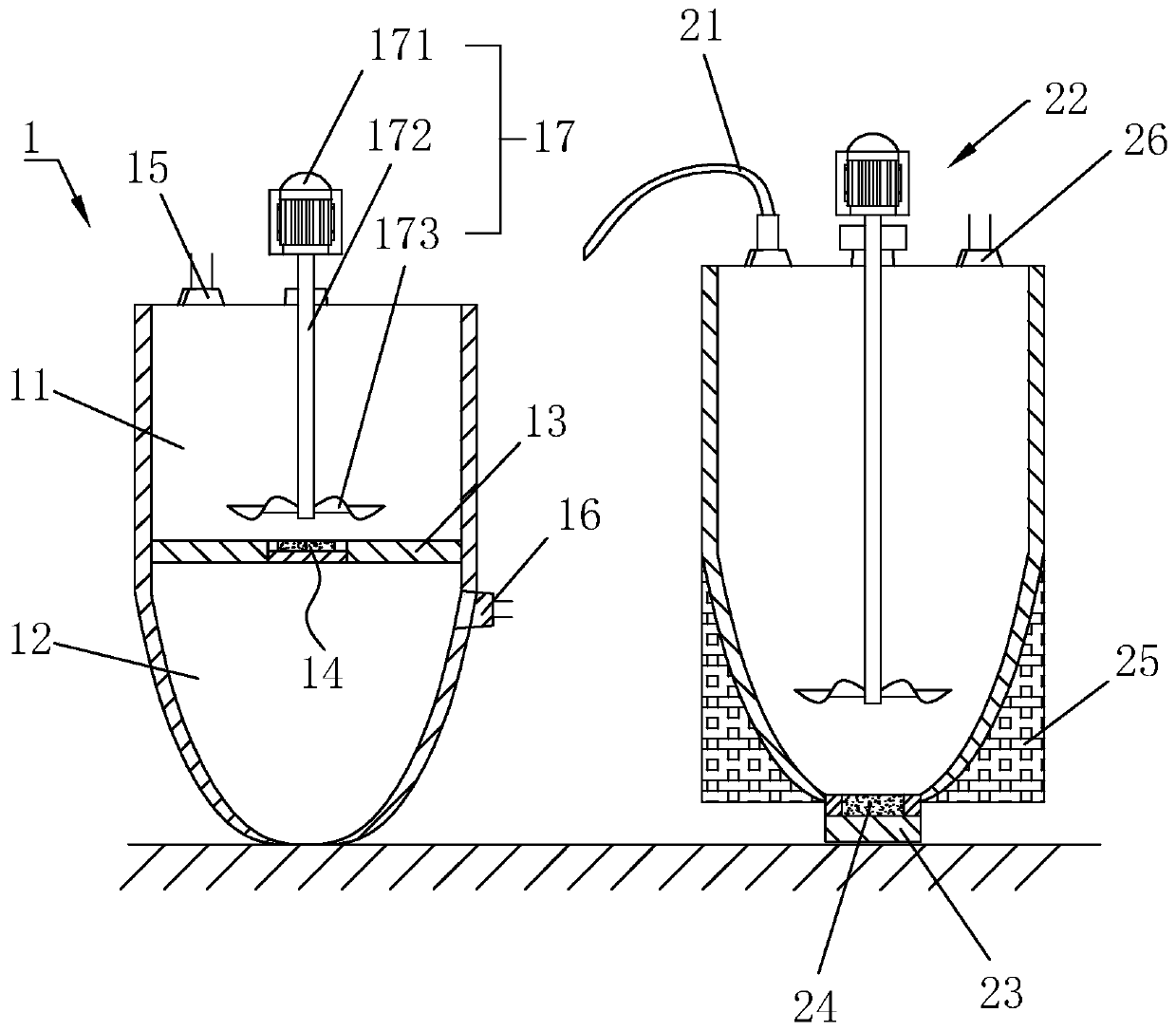

Image

Examples

Embodiment 1

[0024] Example 1, 100 g of the crude bepotastine besylate was added to 400 ml of an aqueous solution containing 40 g of potassium carbonate, cooled to 5-10° C., stirred until the solution was clear, and filtered to obtain a clear solution;

[0025] Add 100ml of dichloromethane to the solution, extract, separate, remove the water phase, then add 100ml of toluene, extract, separate, and collect the organic phase;

[0026] Add 96ml of 5mol / L hydrochloric acid to the organic phase, and slowly precipitate solids as the acid is added. During the dropping process, the temperature is controlled at 5-10°C, the pH is controlled at 8, and the stirring time is 30min;

[0027] Add the filtered solid to 1000mL water to make a slurry for 2h, filter, and repeat once;

[0028] The final obtained solid was added to a vacuum drying oven, and dried under reduced pressure at 85° C. for 24 hours (desiccant P2O5) to obtain 69 g of the product, with a yield of 69%. The purity of the final product is...

Embodiment 2

[0029] Example 2, add 100 g of crude bepotastine besilate to 400 ml of an aqueous solution containing 100 g of sodium carbonate, cool down to 5-10° C., stir until the solution is clear, and filter to obtain a clear solution.

[0030] Add 400ml of dichloromethane into the solution, extract, separate the liquid, remove the water phase, add 400ml of toluene therein, extract, extract, separate the liquid, and collect the organic phase;

[0031] Add 96ml of 5mol / L hydrochloric acid to the organic phase, and slowly precipitate solids with the addition of acid. During the dropping process, the temperature is controlled at 5-10°C, the pH is controlled at 7, and the stirring time is 30min;

[0032] The resulting solid was added to 5000mL water to make a slurry for 2h, filtered, and then repeated once;

[0033] The final obtained solid was added to a vacuum drying oven, and dried under reduced pressure at 85° C. for 24 hours (desiccant P2O5) to obtain 66 g of the product, with a yield o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com