Bright glaze ceramic tile and preparation method thereof

A technology for ceramic tiles and ceramic tile blanks, which is applied in clay products, other household appliances, applications, etc., can solve the problems of affecting the appearance and decoration effect of ceramic tiles, poor integration of blank glaze, unfavorable environmental protection and energy saving, etc. The effect of flatness, surface smoothness, and enhancement of pattern decoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

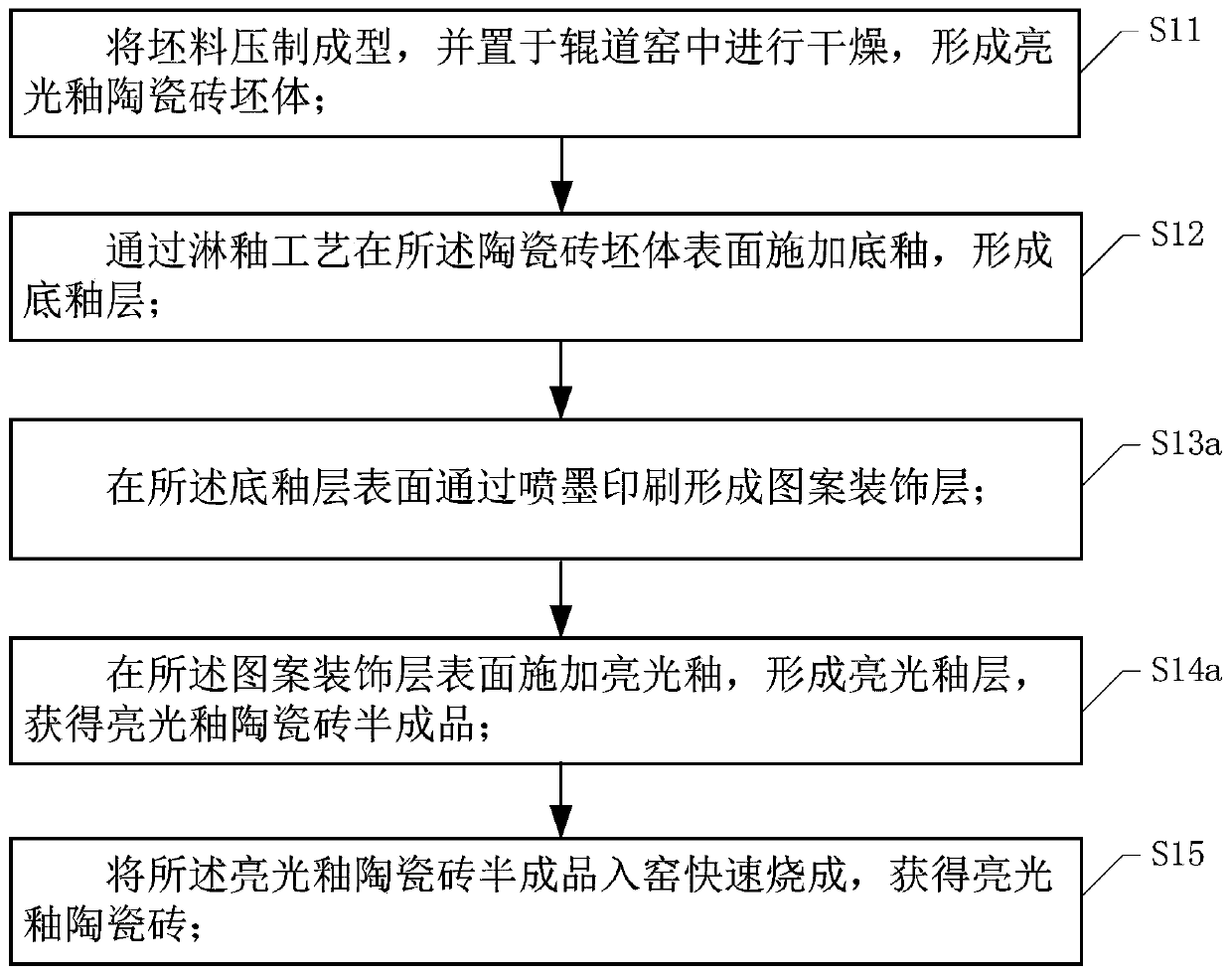

[0108] A preparation method for bright glazed ceramic tiles, comprising:

[0109] Step S11, pressing the blank into shape, and placing it in a roller kiln for drying to form a bright glazed ceramic tile body;

[0110] Step S12, applying an underglaze on the surface of the ceramic tile body through a glazing process to form an underglaze layer;

[0111] Step S13a, forming a pattern decoration layer on the surface of the underglaze layer by inkjet printing;

[0112] Step S14a, applying bright glaze on the surface of the pattern decoration layer to form a bright glaze layer to obtain

[0113] semi-finished bright glazed ceramic tiles;

[0114] Step S15, putting the semi-finished bright glazed ceramic tiles into a kiln for rapid firing to obtain bright glazed ceramic tiles;

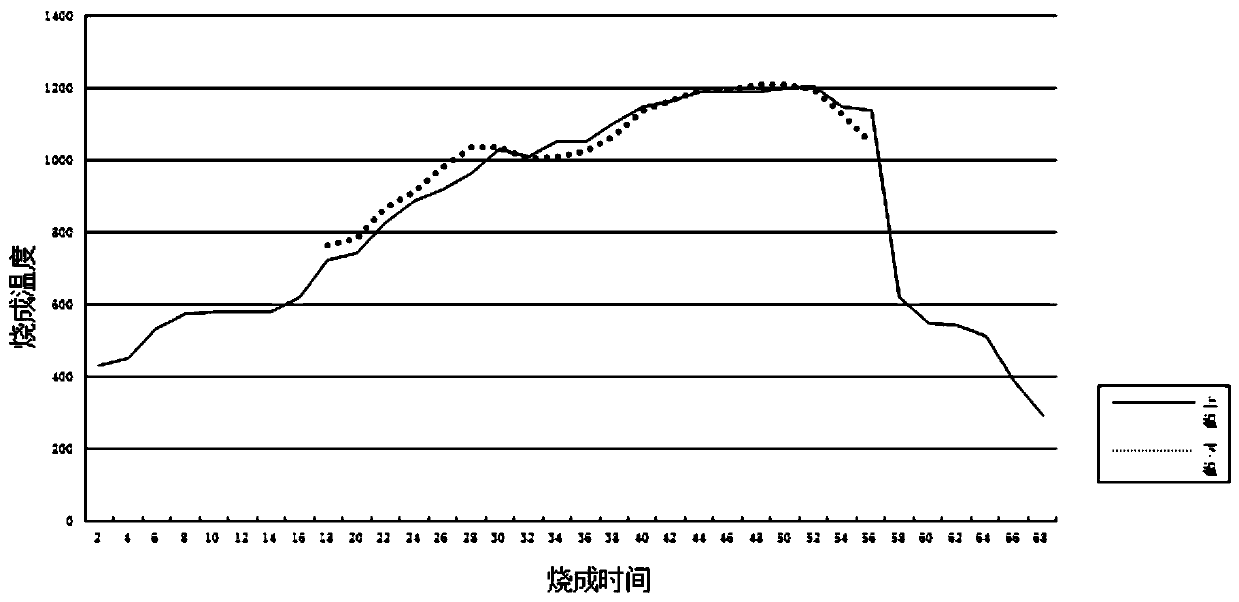

[0115] Wherein, the firing period in the step S15 is 45-70 minutes; the firing temperature is not greater than 1210°C.

[0116] The chemical composition of the bottom glaze in the step S12 includes:

[0...

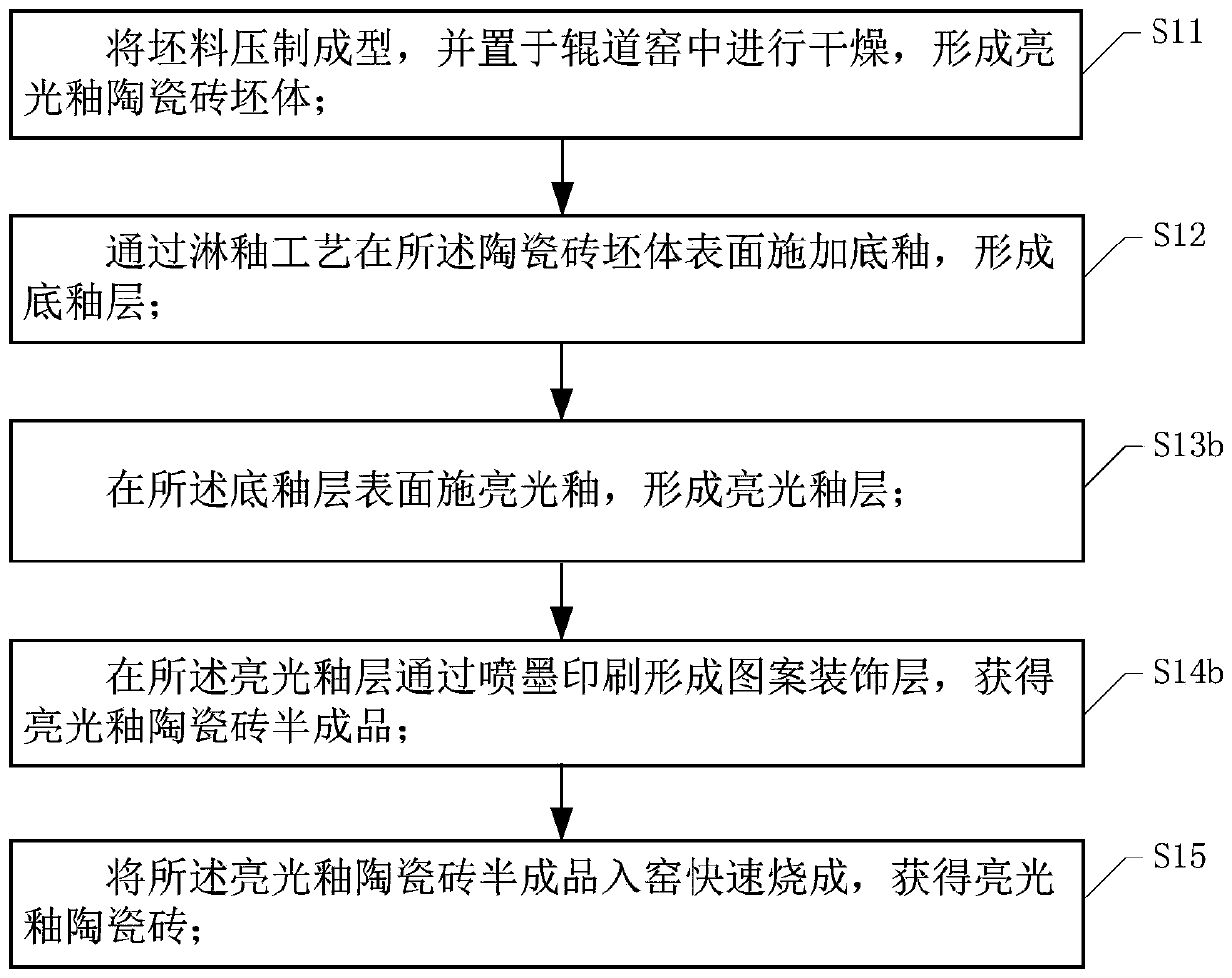

Embodiment 2

[0143] The difference between this embodiment and the first embodiment above is:

[0144] The chemical composition of the bottom glaze in the step S12 is by mass percentage, and specifically includes:

[0145] SiO 2 53.77%, Al 2 o 3 26.83%, Fe 2 o 3 0.17%, CaO 1.38%, MgO 3.98%, K 2 O2.67%, Na 2 O 3.04%, ZrO 2 8.16%.

Embodiment 3

[0147] The difference between this embodiment and the first embodiment above is:

[0148] The chemical composition of the bright glaze in the step S14a is calculated by mass percentage, and specifically includes:

[0149] SiO 2 53.54%, Al 2 o 3 16.52%, Fe 2 o 3 0.28%, CaO 14.10%, MgO 2.03%, K 2 O3.59%, Na 2 O 2.66%, ZnO 2.94%, B 2 o 3 0.30%, TiO2 0.04%, BaO 4.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com