A kind of glaze for double-layer glazing, preparation method and application

A glaze and double-layer technology, applied in the field of ceramics, can solve problems such as cracks in the glaze layer, mesh deformation, and screen wire displacement, so as to reduce glaze stain defects, improve customer satisfaction, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

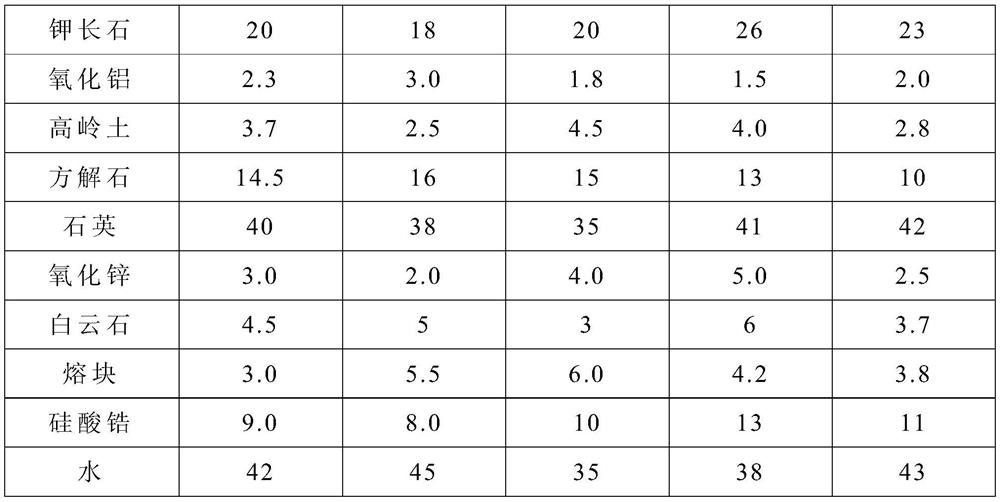

[0023] A kind of glaze material for double-layer glazing, its specific formula is shown in Table 1.

[0024] Table 1 Glaze formula table

[0025] Unit: grams

[0026]

[0027]

[0028] The glaze is prepared by the following method, which specifically includes the following steps:

[0029] (1) The preparation method of bottom glaze, comprises the following steps:

[0030] 1) Mix the components in the glaze formula, pass through wet iron removal, ball milling, and pulping in sequence, then pass through a 140-mesh static sieve, then pass through an electric iron removal, a 200-mesh vibrating screen, and an iron removal tank in turn, and then pass through 140 mesh static sieves, obtain slurry A;

[0031] 2) Add carboxymethyl cellulose sodium to the slurry A and stir evenly to obtain the bottom glaze; the carboxymethyl cellulose sodium accounts for 0.15% to 0.3% of the total mass of the slurry A;

[0032] (2) The preparation method of face glaze, specifically comprises th...

Embodiment 2

[0038] A method for applying a glaze in double-layer glazing (the glaze is prepared by the method described in Example 1), specifically comprising the following steps: first spraying the bottom glaze on the surface of the green body, the thickness of the sprayed glaze is 0.15-0.20 mm ; Then spray the surface glaze on the green body, and the thickness of the spray glaze is 0.6-0.8 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com