A kind of grass-shaped zinc oxide photocatalytic film coated with nano-silver and its preparation method

A photocatalytic thin film, zinc oxide technology, applied in the field of photocatalysis, can solve the problems of reduced specific surface area of the substrate, weakened photocatalytic performance, aggregation of Ag nanoparticles, etc., to achieve improved photocatalytic performance, excellent photocatalytic activity, and avoid agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare the seed layer solution: dissolve 0.11 g of zinc acetate with 25 mL of absolute ethanol in a 58 °C water bath for 0.5 h to obtain solution A; meanwhile, stir and dissolve 0.075 g of sodium hydroxide with 25 mL of absolute ethanol at room temperature for 0.5 h to obtain Solution B. A and B solutions were mixed with each other in a water bath at 70 °C and stirred for 2 h, and then poured into a prepared clean beaker and aged at room temperature for 4 h to obtain a uniform seed layer solution.

[0027] Preparation of the seed layer substrate: the seed layer solution was coated on the glass substrate with a spin coater, and finally the substrate was placed in a crucible and annealed in a resistance oven at 400 °C for 1 h, and the seed layer substrate was obtained after air cooling.

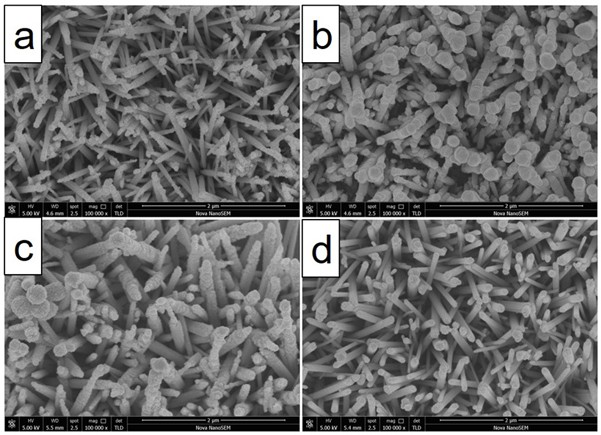

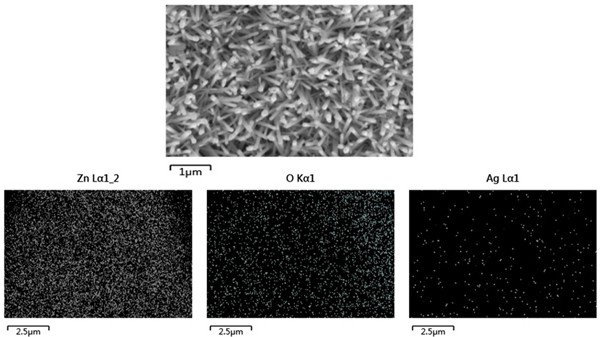

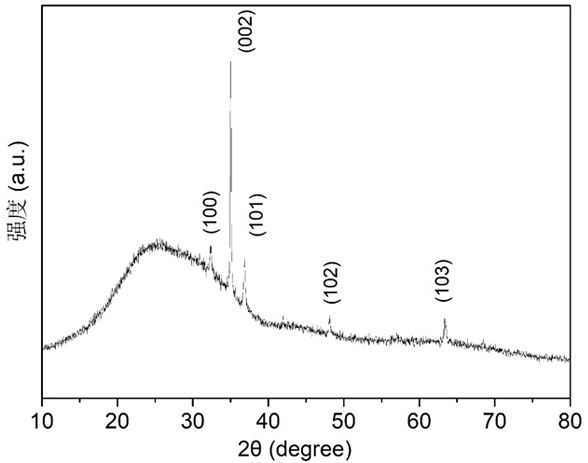

[0028] Preparation of tussock-like zinc oxide substrate: place the seed layer substrate in an aqueous solution containing 0.05 M zinc nitrate hexahydrate, 0.05 M hexamethylenetetramine,...

Embodiment 2-4

[0031] Keep other steps unchanged, change the addition amount of stannous chloride, trifluoroacetic acid and silver nitrate, and adjust the concentrations in the following table to obtain samples Ag / ZnO-2, Ag / ZnO-3 and Ag / ZnO-4 respectively.

[0032] Table 1 Experimental material formula list

[0033]

Embodiment 5

[0035]Prepare 10 mg / L RhB solution, take 50 ml each time as organic waste liquid, immerse the glass sample, and stir the degradation solution throughout. In order to achieve adsorption-desorption equilibrium, samples were taken in a dark room without xenon lamp irradiation for 30 min. Then put it under the xenon lamp under dark room conditions for 2.5 h, take 5 ml samples at intervals for ultraviolet absorption test, and keep the height between the lamp source and the liquid level at 9 cm after each sampling. Thus, the concentration of RhB in each time period can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com