Preparation method of silicon dioxide antibacterial microsphere

A technology of silicon dioxide and microspheres, applied in the field of antibacterial nanomaterials, can solve the problems of inability to achieve bacterial aggregation and adhesion, high quaternary ammonium salt addition, poor antibacterial effect, etc., and achieve efficient and long-lasting antibacterial performance and good antibacterial effect , Antibacterial performance, efficient and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 100 parts of N,N-dimethyl-3-aminopropyltrimethoxysilane (Hangzhou Jessica Chemical Co., Ltd.), 120 parts of bromooctane (Aladdin), 0.1 part of p-hydroxyanisole (A Latin) was added to 200 parts of acetonitrile, reacted at 30°C for 8h, and the solution obtained by the reaction was rotary evaporated at 50°C for 2h, and the unreacted alkyl halide and solvent were removed to obtain Silicon-containing quaternary ammonium salt 1 , the structural formula is as follows:

[0042]

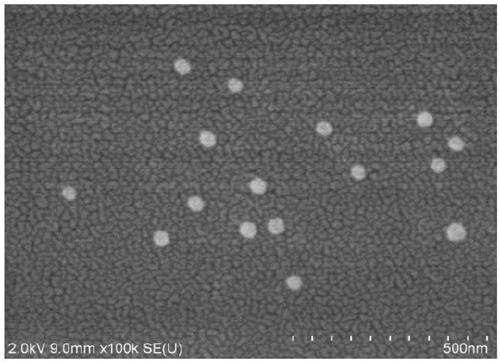

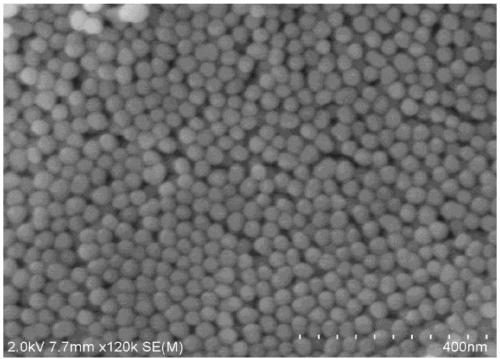

[0043] Mix 10 parts of tetramethoxysilane (Aladdin), 5 parts of 1mol / L sodium hydroxide aqueous solution (Chinese medicine), 5 parts Deionized water and 1 copy Silicon-containing quaternary ammonium salt 1 Prepared by dispersing in 200 parts of toluene (Sinopharm) and reacting at 35°C for 24 hours Silica Antibacterial Microspheres 1 . The antibacterial test was carried out according to relevant standards, and the results of the antibacterial rate test and the particle size of the microsphere...

Embodiment 2

[0045] 100 parts of N,N-dimethyl-3-aminopropyltrimethoxysilane (Hangzhou Jessica Chemical Co., Ltd.), 150 parts of bromodecane (Aladdin), 0.125 parts of 2-tert-butyl-p-phenyl Diphenol (Aladdin) was added to 250 parts of ethyl acetate, reacted at 45°C for 10h, and the solution obtained by the reaction was rotary evaporated at 60°C for 1.5h, and the unreacted alkyl halide and solvent were removed to obtain Silicon-containing quaternary ammonium salt 2 , the structural formula is as follows:

[0046]

[0047] Mix 10 parts of tetrapropoxysilane (Aladdin), 10 parts of 0.5mol / L potassium hydroxide aqueous solution (Chinese medicine), 5 parts deionization water and 1 copy Silicon-containing quaternary ammonium salt 2 Prepared by dispersing in 250 parts of acetonitrile (Sinopharm) and reacting at 75°C for 20 hours Silica antibacterial micro ball 2 . The antibacterial test was carried out according to relevant standards, and the results of the antibacterial rate test an...

Embodiment 3

[0049] 100 parts of N,N-dimethyl-3-aminopropyltrimethoxysilane (Hangzhou Jessica Chemical Co., Ltd.), 250 parts of bromododecane (Aladdin), 0.15 parts of p-hydroxyanisole ( Aladdin) was added to 300 parts of acetone, reacted at 60°C for 12h, and the solution obtained by the reaction was rotary evaporated at 70°C for 1h, and the unreacted alkyl halide and solvent were removed to obtain Silicon-containing quaternary ammonium salt 3 , the structural formula is as follows:

[0050]

[0051] Mix 10 parts of TEOS (Chinese medicine), 15 parts of ammonia water (Chinese medicine), 5 parts Deionized water Disperse in 300 parts of ethanol (Sinopharm), pre-react at 45°C for 4 hours, add 1 part of the above mixed solution dropwise Silicon-containing quaternary ammonium salt 3 , prepared by reacting at 50°C for 24h Silica antibacterial micro ball 3 . The antibacterial test was carried out according to relevant standards, and the results of the antibacterial rate test and the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com