Optical fiber coating even shaking device and method

A coating and optical fiber technology, which is applied in the field of optical fiber coating shaking device, can solve the problems of unclean mold curing, cost reduction, uneven coating, etc., and achieve the effects of reducing pretreatment time, reducing production energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

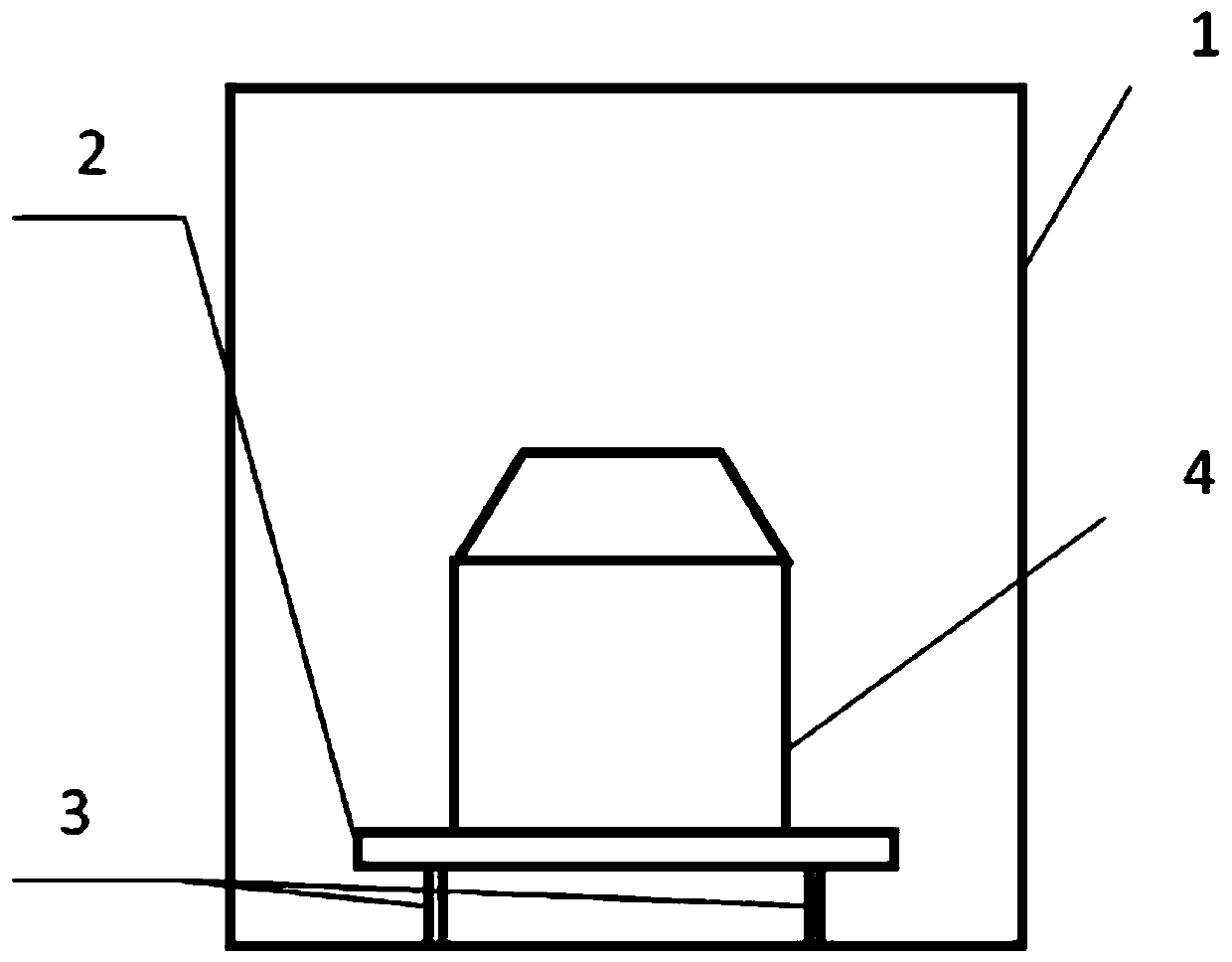

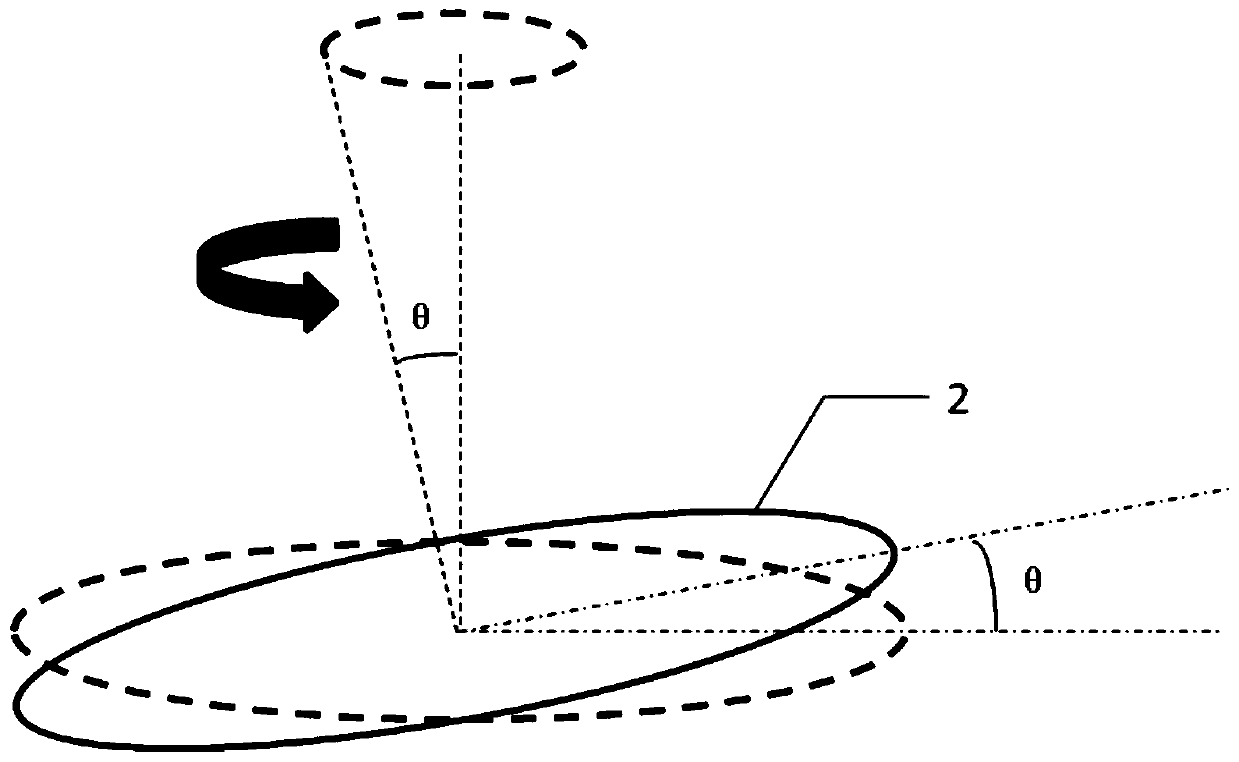

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0023] As mentioned in the background art, there are coating defects in optical fiber coatings in the prior art, which are mainly caused by uneven coating, dirty molds and poor curing. Among them, the unevenness of the coating is caused by the incomplete dispersion of the additives and the high density of air bubbles in the coating before wire drawing. Moreover, the current pretreatment of the paint needs to be left to stand in an oven at 40-80°C for 6-8 hours, and the recovered paint is left to stand for more than 12 hours. The processing time is long and the heat preservation energy consumption is high, which is not conducive to rapid production and energy consumption reduction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com