A complete set of equipment and method for energy-saving pressure swing adsorption tail gas recovery and utilization

A technology of tail gas recovery and pressure swing adsorption, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of power consumption, large energy consumption of drying equipment, and high waste, so as to save power consumption and reduce Operating cost, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

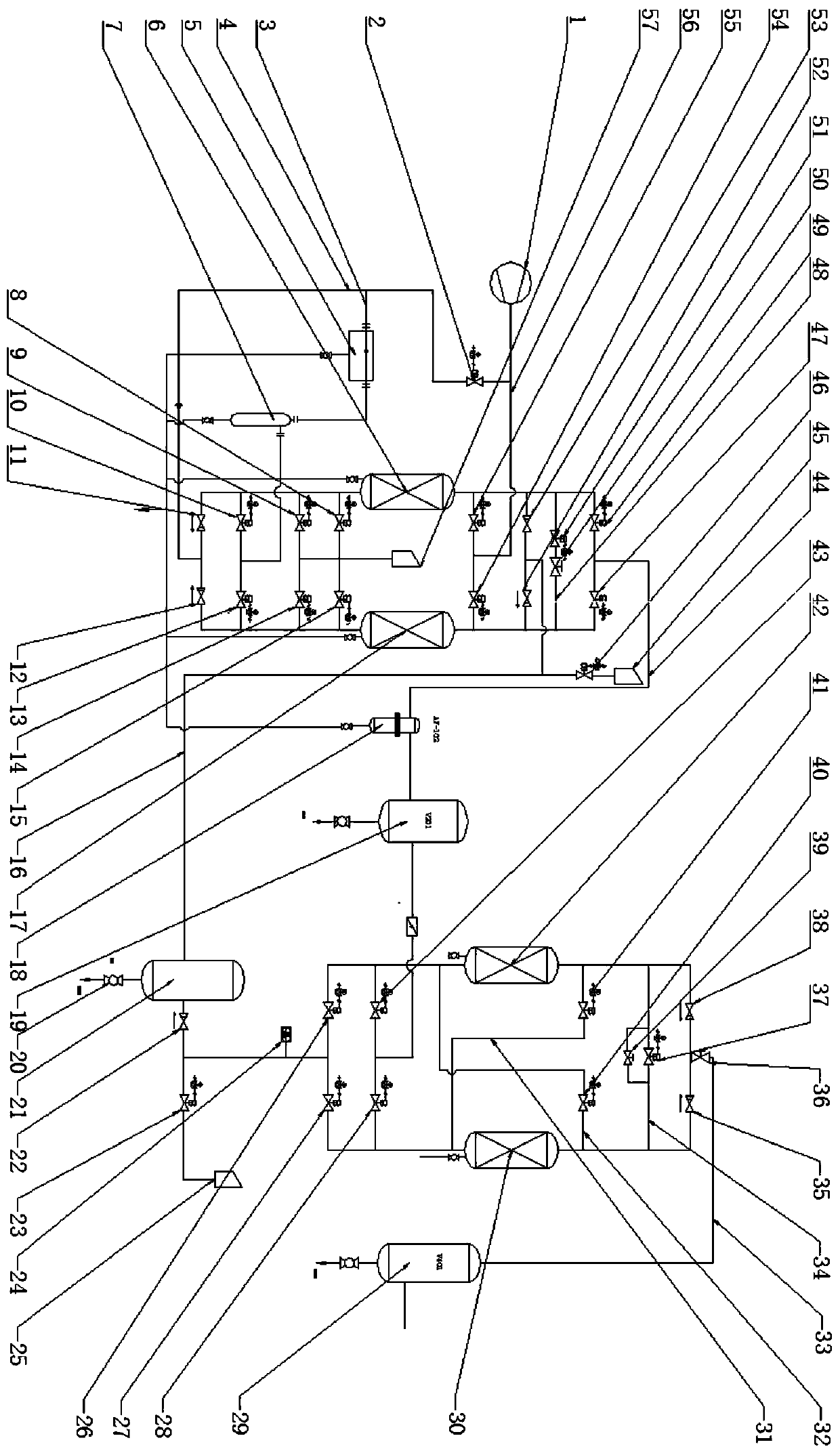

[0045] see figure 1 , a complete set of equipment for energy-saving pressure swing adsorption tail gas recovery and utilization, including an intake pipeline, a compression heat regeneration drying device, a gas transmission pipeline, a tail gas regeneration pipeline 16 and an oxygen and nitrogen separation device, and the intake pipeline includes a first The air intake pipeline 3 and the second air intake pipeline 56; the air intake ends of the first air intake pipeline 3 and the second air intake pipeline 56 are connected with a centrifugal compressor 1; There is a first pneumatic valve 2, a cooler 5 and a gas-liquid separator 7; the gas outlets of the first air intake line 3 and the second air intake line 56 are connected to the compression heat regenerative drying device;

[0046] The heat of compression regenerative drying device includes a first drying tower 6 and a second drying tower 17, the first drying tower 6 and the second drying tower 17 are filled with an alumina...

Embodiment 2

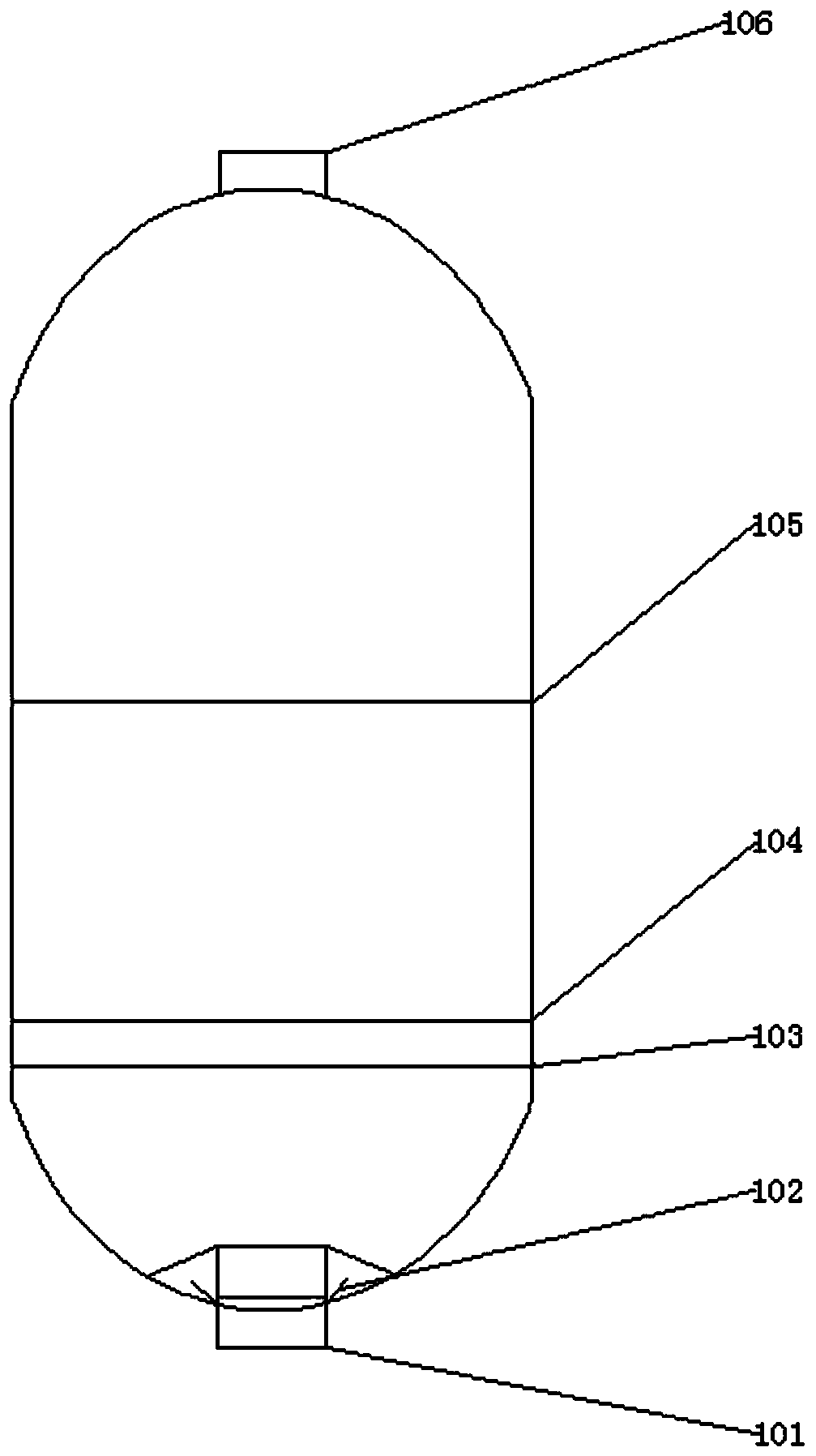

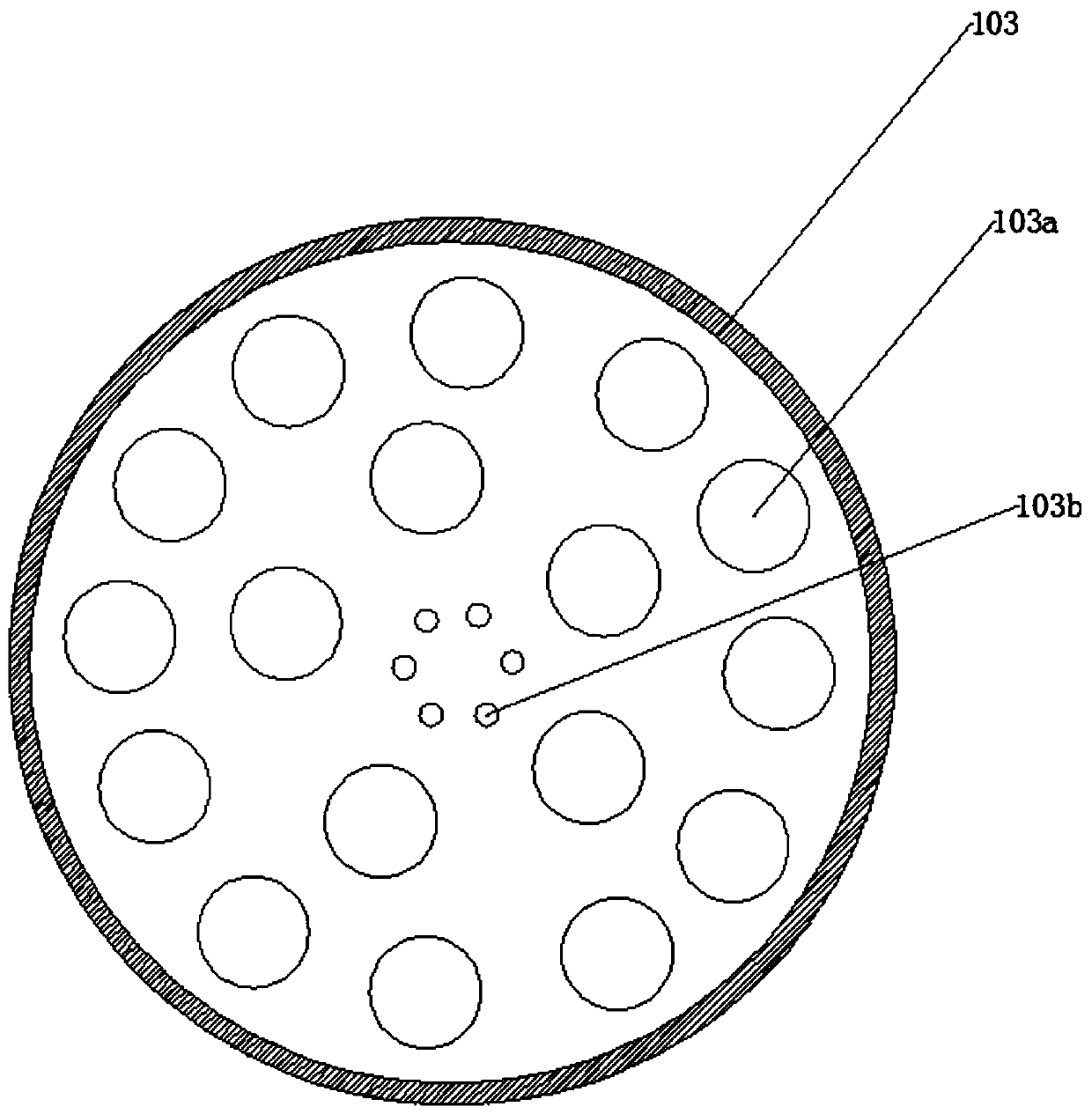

[0052] see figure 2 , image 3 , the adsorption tower can also be referred to as an adsorber, an adsorption bed, or a separator, and refers to a container filled with an adsorbent. The adsorbent has a strong adsorption capacity for components that are more easily adsorbed in the air, such as nitrogen production. In the process, an oxygen adsorbent is used, that is, a molecular sieve that absorbs oxygen. Oxygen is a strong adsorption component, nitrogen is a weak adsorption component, and a strong adsorption component is a relatively weak adsorption component; in the oxygen production process, nitrogen adsorption is used. Nitrogen is a strongly adsorbed component and oxygen is a weakly adsorbed component. In this embodiment, the internal structure of the adsorption tower is, from bottom to top, an air inlet 101, an airflow baffle 102, an airflow distributor 103, an alumina adsorption layer 104, a molecular sieve adsorption layer 105, and an air outlet 106. The plate 102 is c...

Embodiment 3

[0059] An energy-saving method for recovering and utilizing PSA tail gas, the operation of the compression heat regeneration drying device includes the following steps:

[0060] Step 1, the first drying tower 6 is adsorbed, the second drying tower 17 is regenerated, the ninth pneumatic valve 54, the second check valve 12, the second pneumatic valve 10, the eleventh pneumatic valve 49 are opened, and the centrifugal compressor 1 discharges The high-temperature compressed air above 110°C enters the second drying tower 17, purges and regenerates the second drying tower 17, enters the cooler 5 and the gas-liquid separator 7, and then enters the first drying tower 6, and the first drying tower 6 enters the drying working state , the compressed air obtained after drying with a low dew point passes through the dust filter 18 and enters the air buffer tank 19;

[0061] Step 2, the first drying tower 6 is adsorbed, the second drying tower 17 is decompressed, the first drying tower 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com