Roasted snack machine with salt left

A technology of cargo plane and salt frying, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of cumbersome operation, loss of heat, and uneven heating, etc., and achieve uniform heating, simple operation, and good light and color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

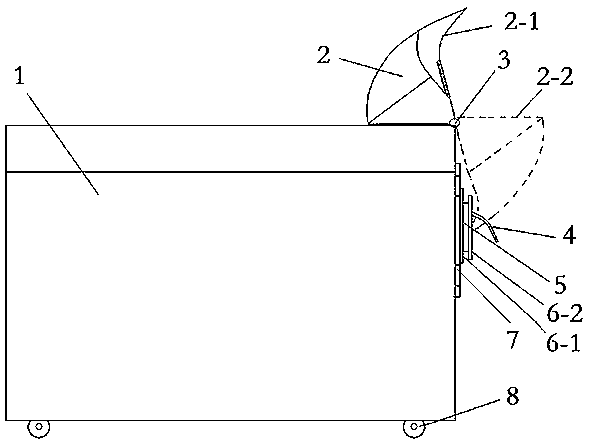

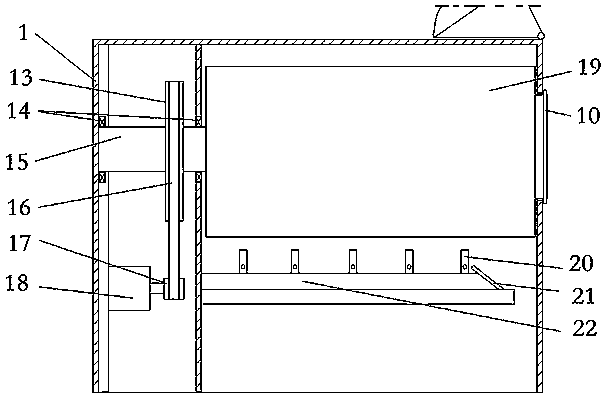

[0022] See Figure 1-2 , one end of the upper part of the casing 1 equipped with casters 8 is connected to the flip feeding hopper 2 through the hinge shaft 3, and the feeding hopper 2 has a feeding port 2-2 and a feeding port 2-1; when not feeding, turn the feeding hopper 2 to the machine On the top of the shell 1, when feeding, turn the feeding hopper 2 down, its feeding port 2-2 faces upwards, and the feeding port 2-1 is designed as an angled shape, and the feeding port 2-1 can extend into the opening of the drum ( That is, after the machine cover is buckled, observe the position of the feeding port 9) for feeding. See image 3 , a drum is arranged in the casing 1, the outermost circumference of the drum is an outer cylinder 19, the two ends are welded with end plates, the inner end of the drum is welded with a rotating shaft 15, and the rotating shaft 15 is assembled in the casing 1 through a bearing 14 and a support plate, The outer end of the drum is connected to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com