Vision-based abnormal state monitoring and fault diagnosis method for digital workshop MES system

A technology of fault diagnosis and abnormal state, applied in the direction of digital transmission system, transmission system, data exchange network, etc., can solve the problems of insufficient sensor arrangement, insufficient relevant data extraction, processing and analysis, affecting fault or abnormal detection and analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

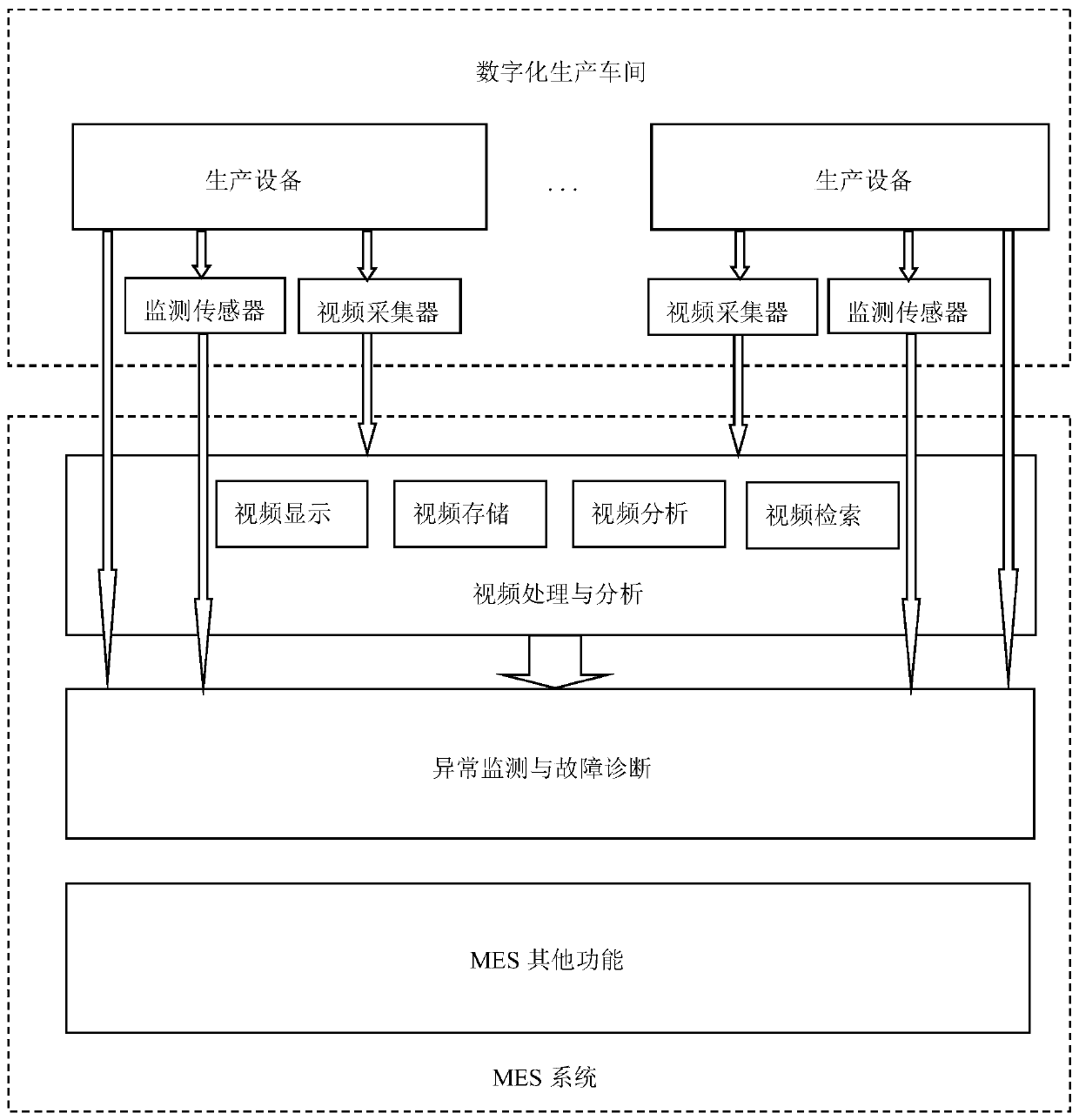

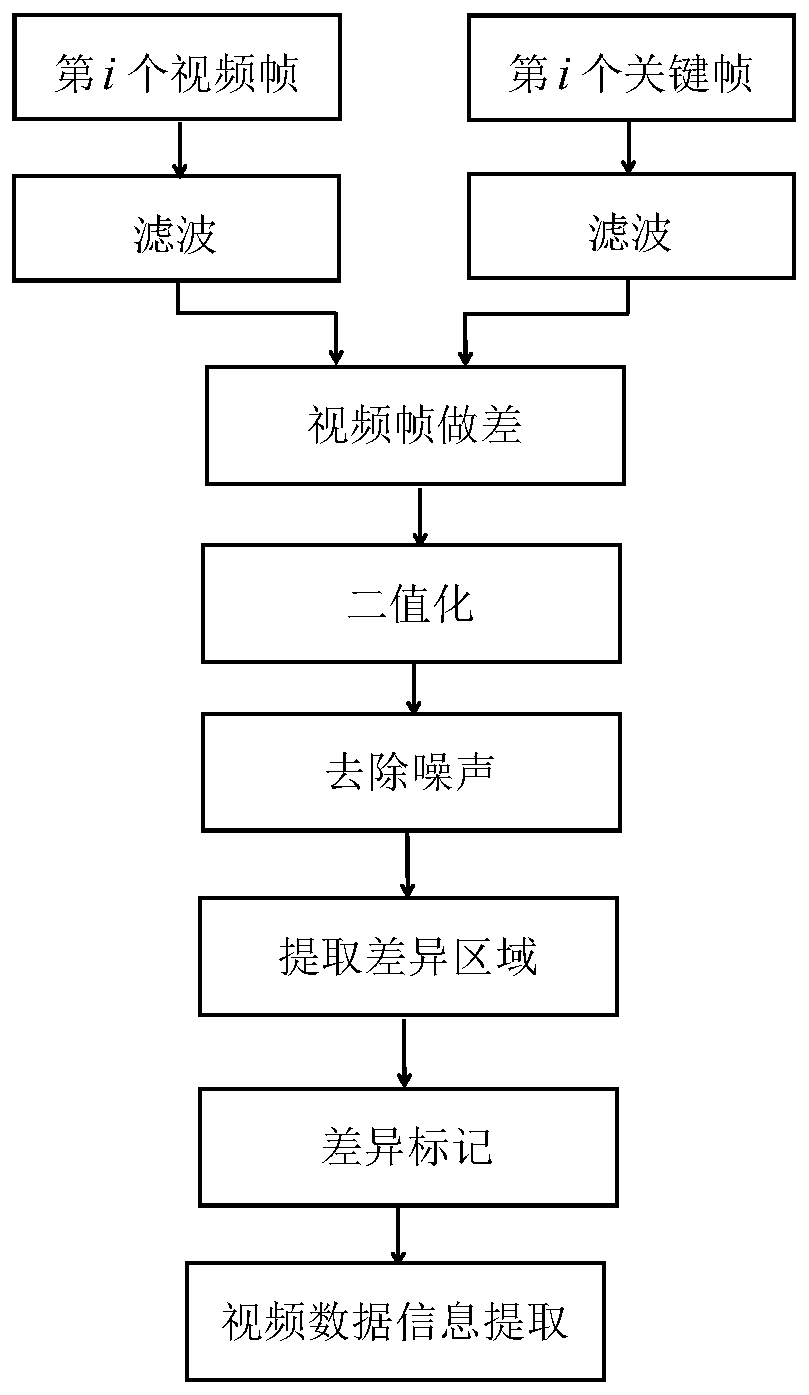

[0048] like figure 1 As shown, a specific embodiment of the present invention is a vision-based abnormal state monitoring and fault diagnosis method for the MES system of a chemical filling digital workshop. Integrate video acquisition equipment, video analysis and processing modules, abnormality monitoring and fault diagnosis modules in the MES system. The method of the present invention comprises following two modes:

[0049] 1. Online analysis mode. The video acquisition equipment collects live video in real time, extracts video data information at the current moment through the video analysis and processing module, synthesizes production data, monitoring data and video data information, and sends it to the abnormal monitoring and fault diagnosis module for abnormal monitoring and detection of abnormal events;

[0050] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com