Wear detection system and method for grinding head

A detection system and grinding head technology, which are used in measuring devices, testing wear resistance, image data processing, etc., can solve problems such as no solutions, and achieve the effects of avoiding trouble, saving energy, and improving processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

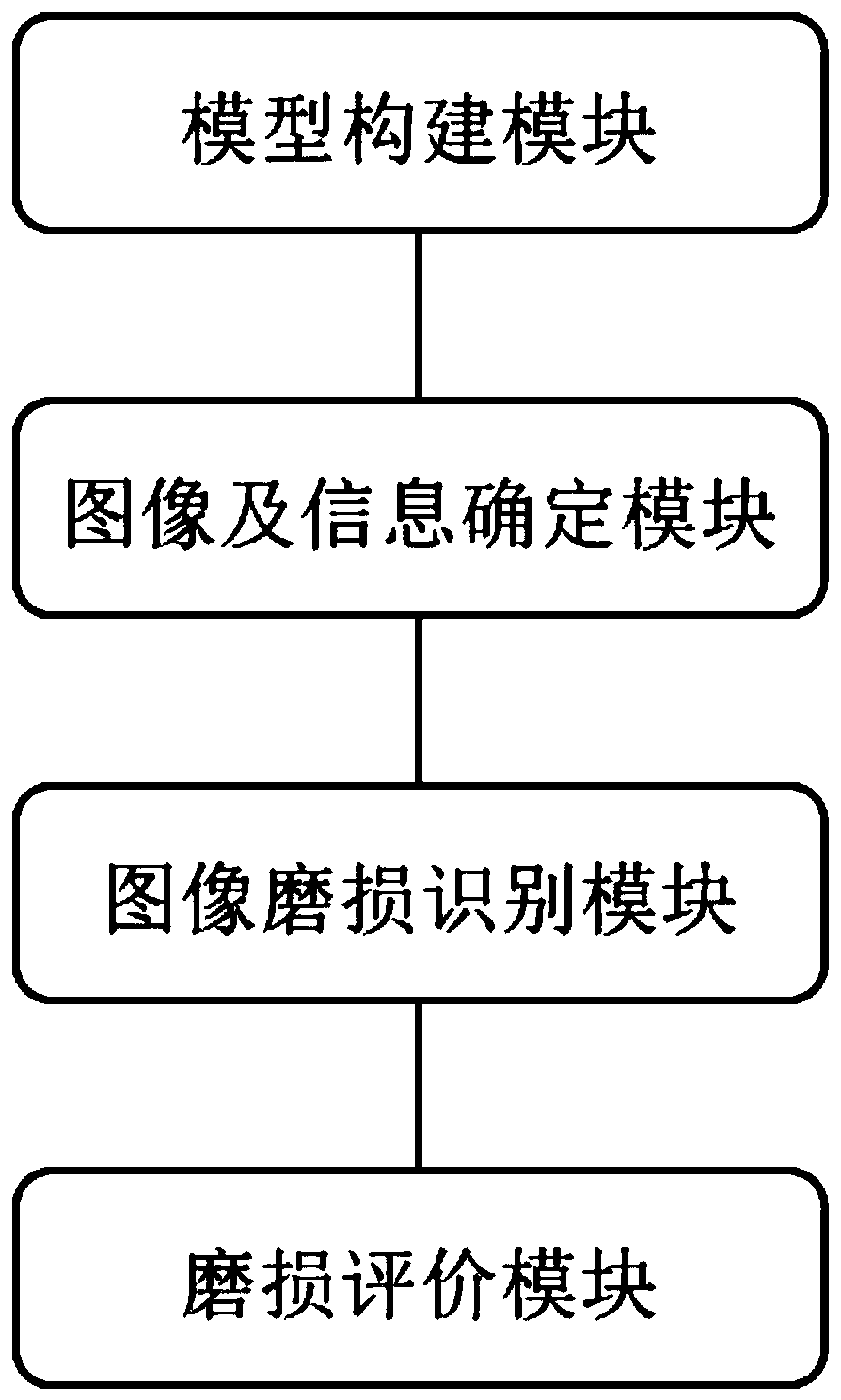

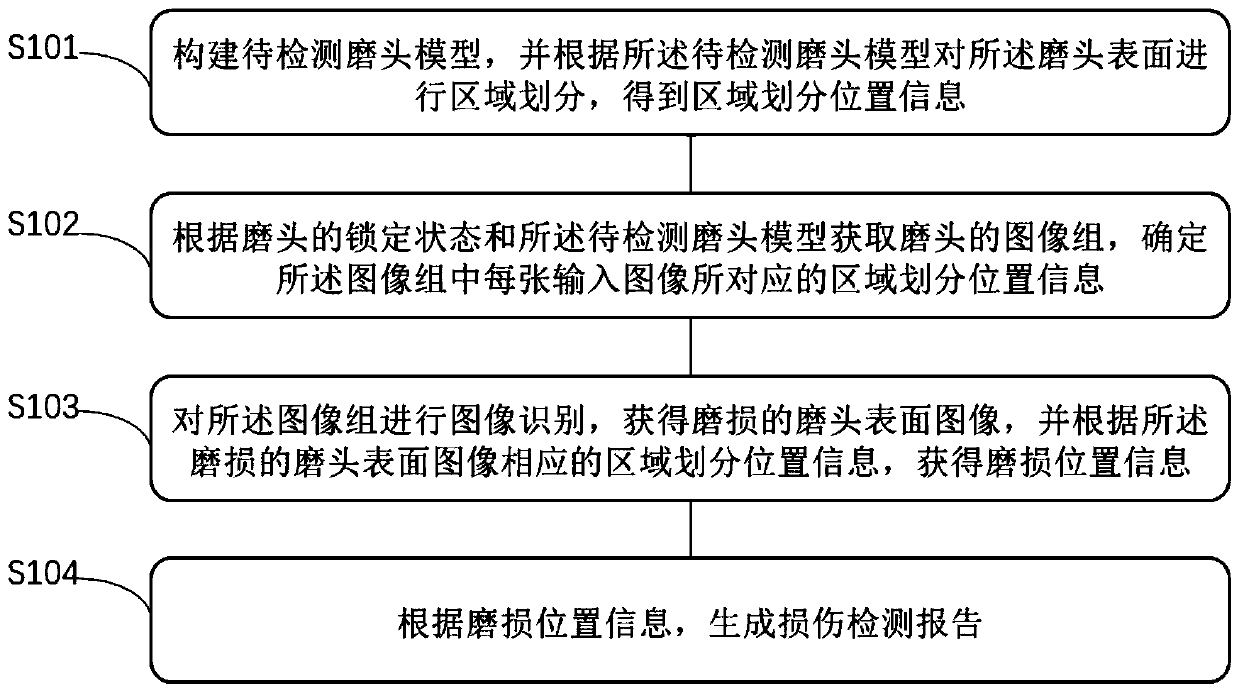

[0026] This embodiment provides a wear detection system for a grinding head, including a grinding head, a model building module, an image and information determination module, an image wear recognition module, and a wear evaluation module, wherein the model building module is used to construct The grinding head model to be detected, and the surface of the grinding head is divided according to the grinding head model to be detected, and the area division position information is obtained; the image and information determining module is used to determine the grinding head according to the locking state of the grinding head and the The grinding head model to be detected obtains the image group of the grinding head, and determines the area division position information corresponding to each input image in the image group; the image wear recognition module is used to perform image recognition on the image group to obtain the worn grinding head. The head surface image, and according t...

Embodiment 2

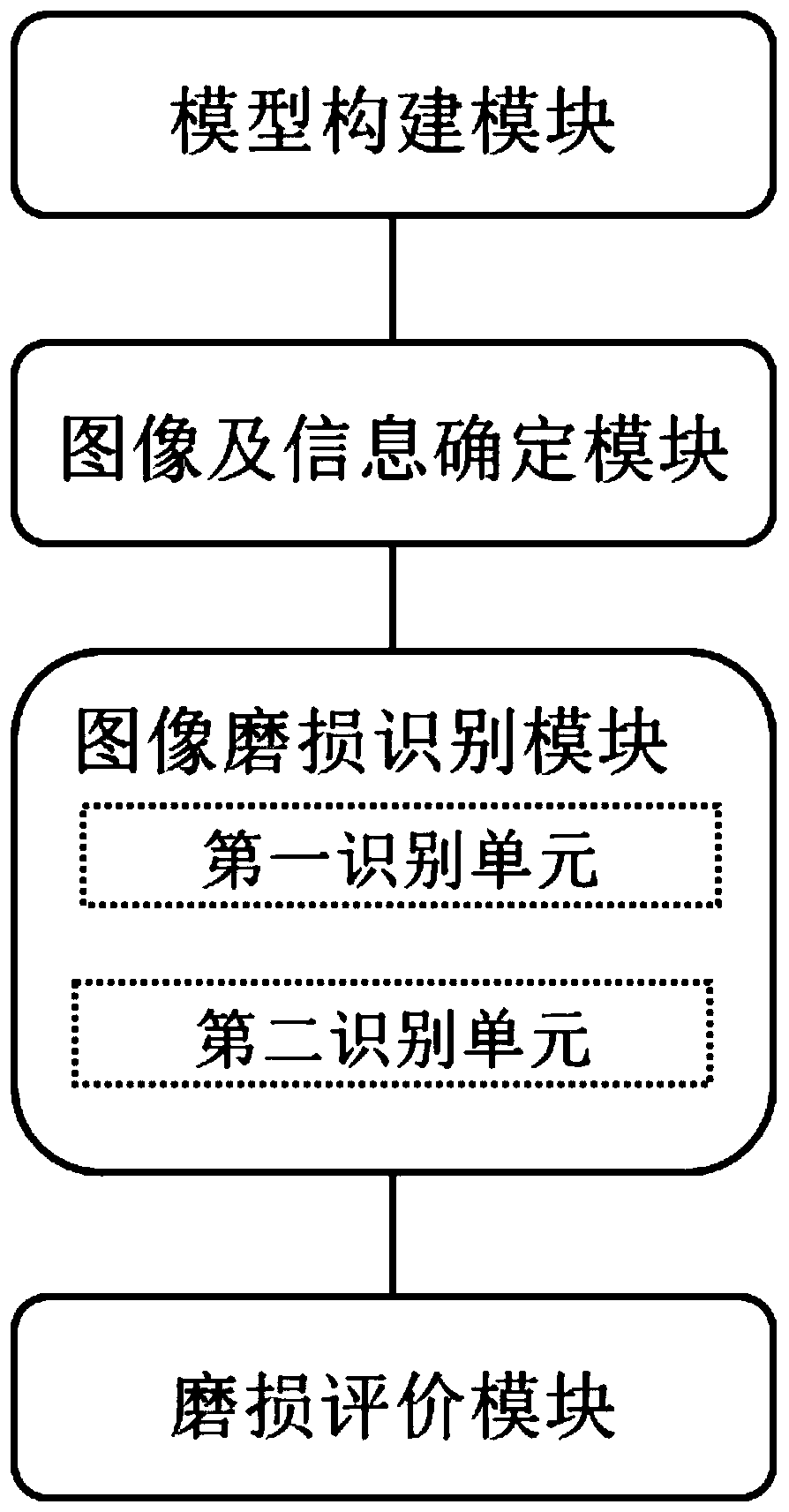

[0042] This embodiment provides a wear detection system for a grinding head, including a grinding head, a model building module, an image and information determination module, an image wear recognition module, and a wear evaluation module, wherein the model building module is used to obtain The model information of the grinding head to be constructed model, and construct the grinding head model to be detected according to the state of the grinding head when it is not put into use and the current state information of the grinding head, and carry out the surface of the grinding head according to the grinding head model to be detected area division, obtaining area division position information, and after the area division, constructing an XY-axis Cartesian coordinate system for each area, so that each feature point of the grinding head falls into the XY-axis coordinate system, and Because the Cartesian coordinate system is constructed after dividing the area, the coordinate inform...

Embodiment 3

[0058] Based on this embodiment, it is basically the same as Embodiment 2, except that: the detection system further includes a rotation detection module and a voltage detection module, wherein, when the detection determines that the remaining thickness value, the average gray value and / or When the area of the matching feature point area is abnormal, the rotation detection module responds and starts to calculate the rotation speed value of the grinding head and the rotation torque value of the connecting rod connected to the grinding head according to the specified time, and calculate the rotation speed value of the grinding head. The amount of change, the amount of change in the rotational torque value of the connecting rod connected to the grinding head, and judge whether the amount of change exceeds the specified value. Specifically, in order to improve the accuracy of detection, the rotation detection module uses the average value of the maximum value and the minimum valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com