Coal mill coal interrupting control method under low-load three-coal mill running mode

A technology of operation mode and control method, applied in combustion method, combustion control, and fuel supply adjustment, etc., can solve problems such as unfavorable safe and stable operation, large fluctuation of boiler steam temperature, and difficulty in control of feed water flow, and achieves a safe and stable operation. The effect of running the request

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

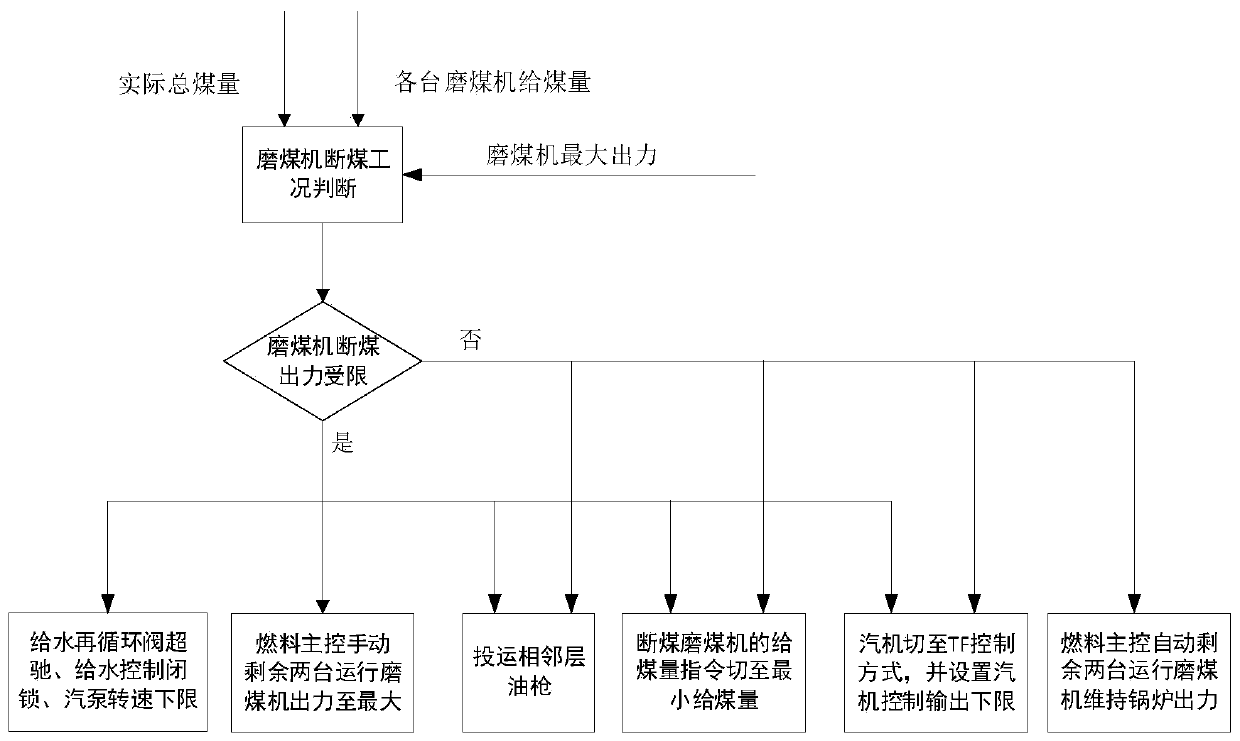

[0039] The implementation of the coal cutting control of the coal mill in the low-load three-mill operation mode of a 660MW unit:

[0040] 1) The operating load of the unit is 260MW, adopting the B / C / D three-mill operation mode, and the DCS control system monitors the operation of the pulverizing system in real time. The coal quantity command of C coal mill is maintained at 35t / h (greater than 15t / h), but the coal quantity feedback is 0t / h (less than 5t / h), which triggers the low-load third mill operation coal mill cut-off signal. The actual total coal volume of the unit before the coal mill is cut off is 110t / h less than the maximum output total coal volume of the remaining two coal pulverizers in normal operation 120t / h (the maximum output of a single coal pulverizer is 60t / h), the following control is adopted Strategy:

[0041]1) Cut the coal feeding command of C coal mill to the minimum coal feeding command of 18t / h;

[0042] 2) The CCS control mode of the unit is releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com