Ejector tube and cooker burner including same

A burner and injection tube technology, which is applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problem of poor air injection ability of the injection tube, so as to improve the injection effect and save installation space , Increase the effect of the inner wall area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

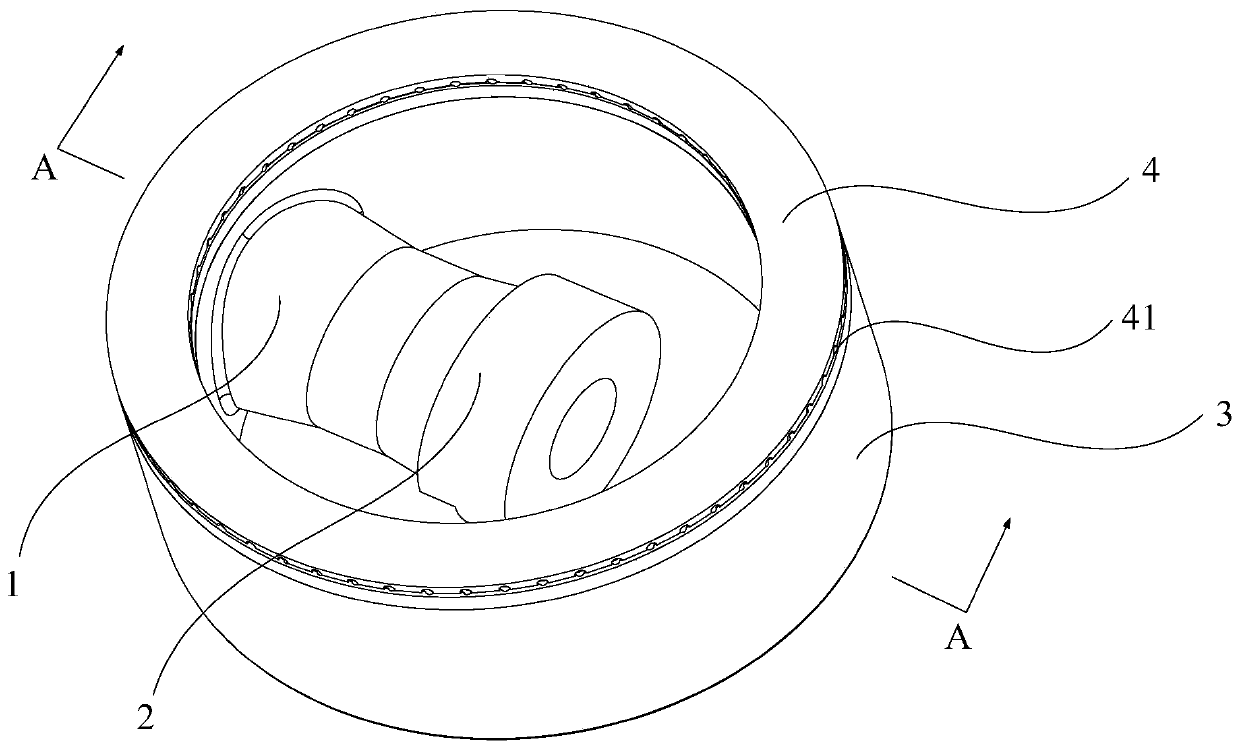

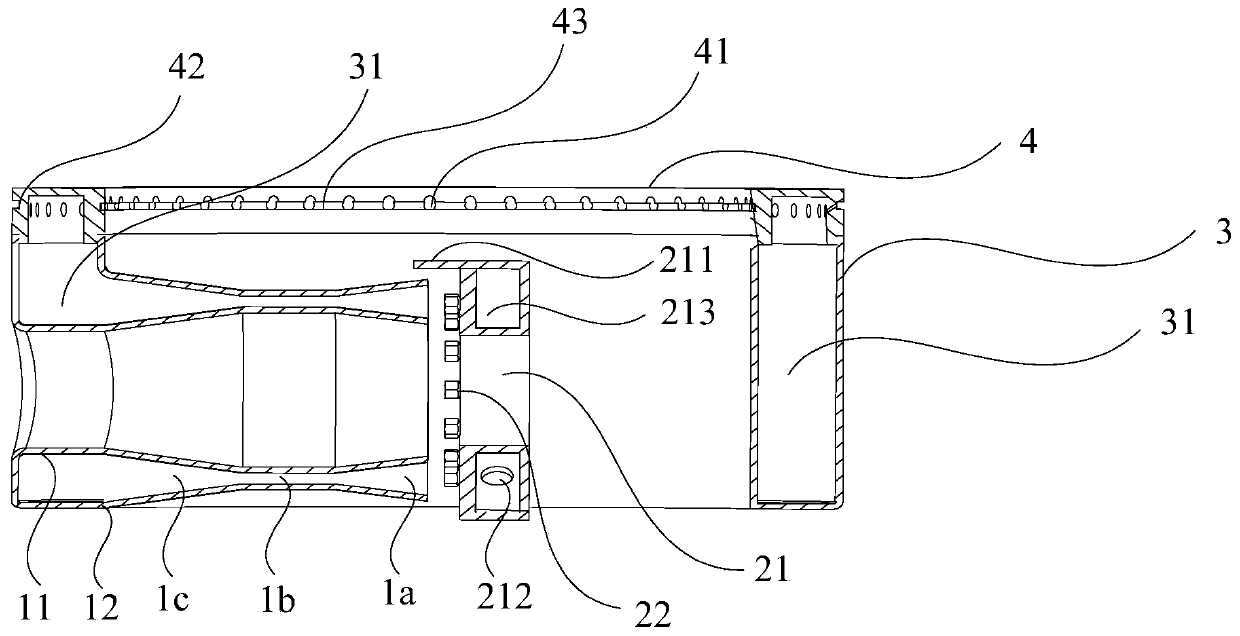

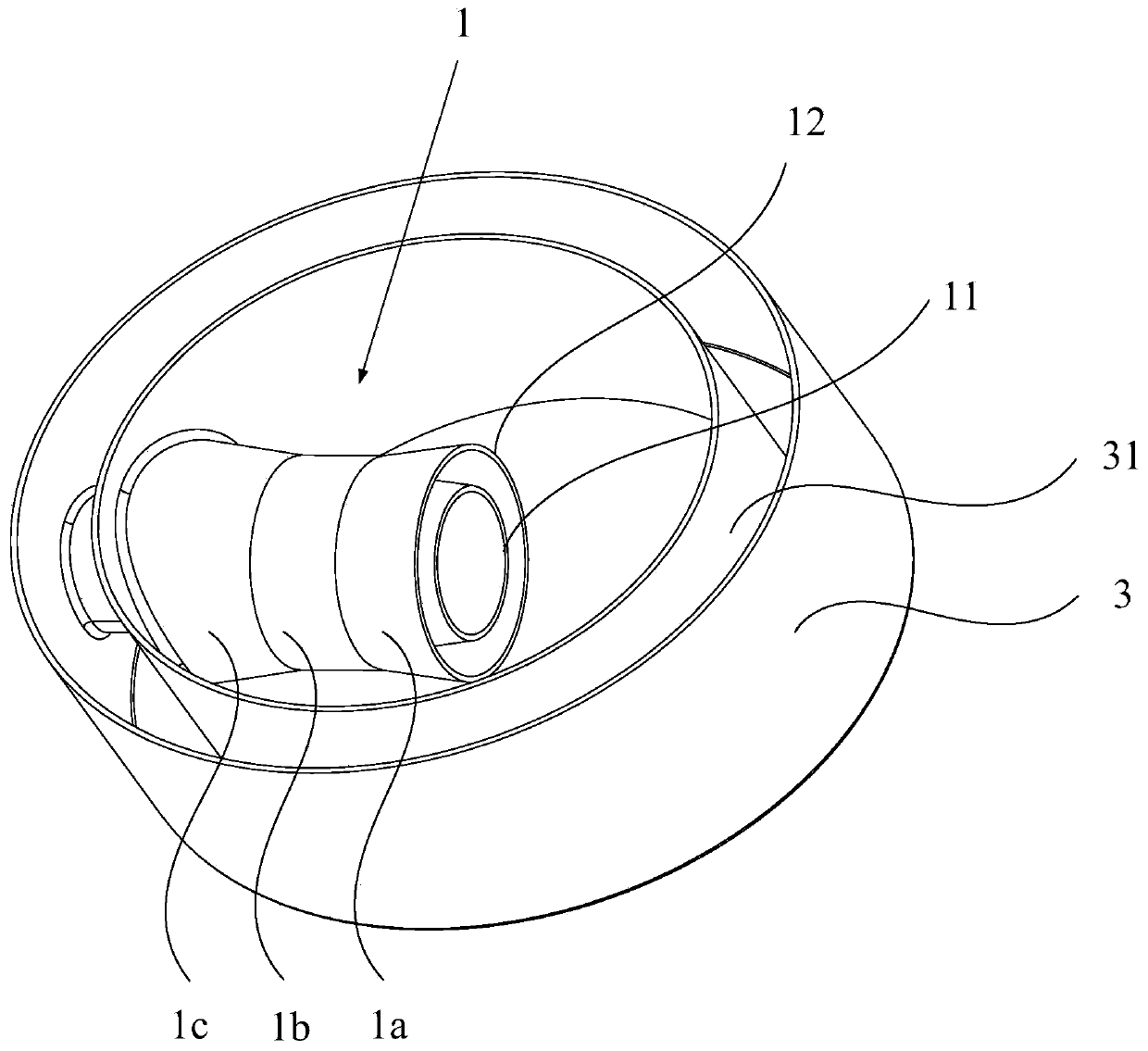

[0054] Such as Figure 1-Figure 6As shown, the present invention discloses an injection tube 1, which includes a pipeline body, the pipeline body is formed by a coaxial inner tube 11 and an outer tube 12, and the annular gap between the inner tube 11 and the outer tube 12 The ejection structure of the ejection tube 1 is formed.

[0055] Compared with the traditional circular, elliptical or other arc-shaped injection tubes 1, the injection tube 1 of this embodiment is formed by coaxial inner tube 11 and outer tube 12, and the inner tube 11 and the outer tube 12 are used. The annular gap between the outer tubes 12 is used as the injection structure of the injection tube 1, and the annular gap can have more inner wall circumference whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com