A softening method for remaining coal pillars in hard coal seams

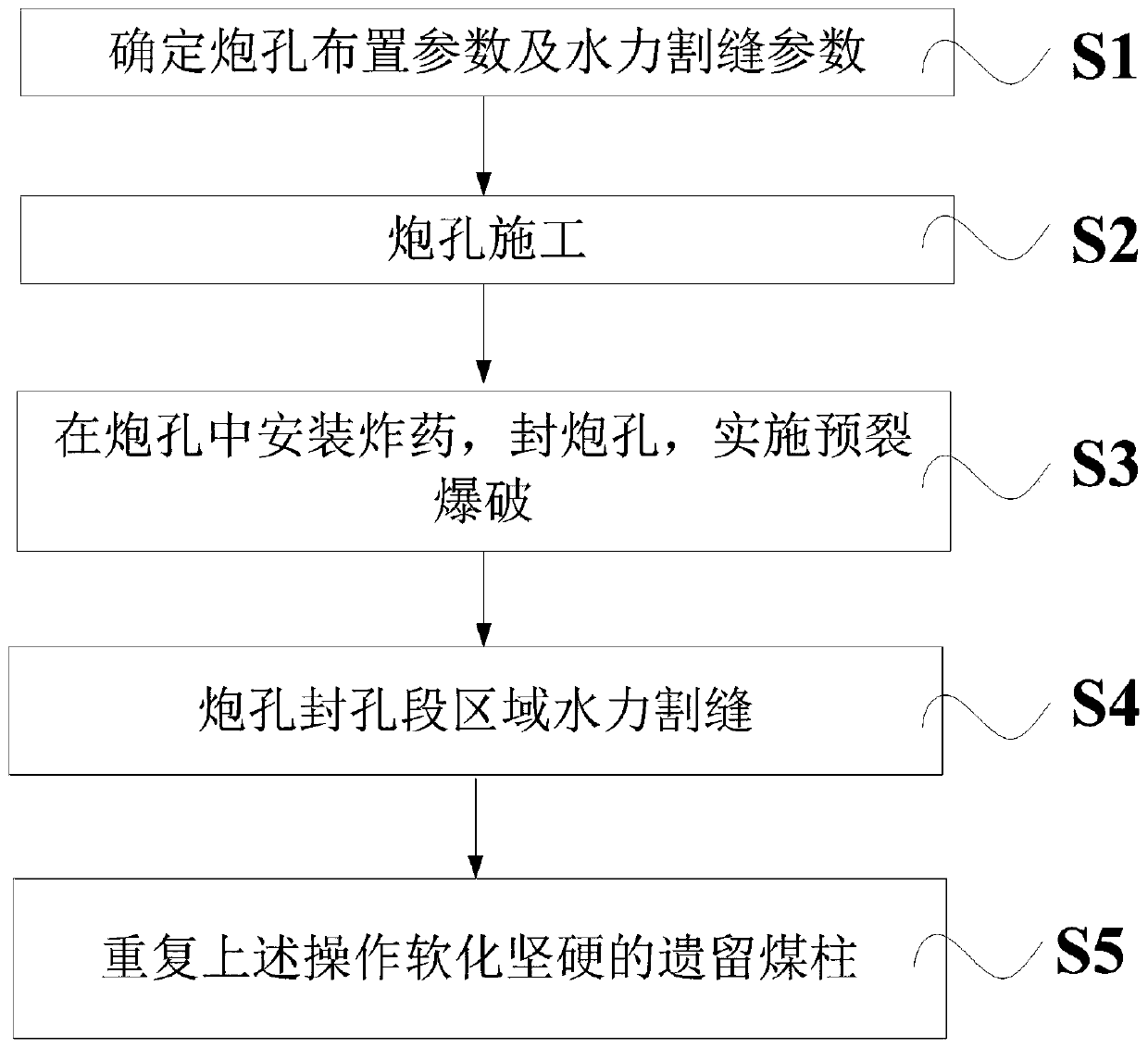

A technology for left coal pillars and coal seams, which is applied in the field of softening of left coal pillars in hard coal seams, can solve problems such as difficulty in mining the remaining coal pillars in hard coal seams, and achieve the effects of good softening effect, small construction amount, and safe and efficient mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

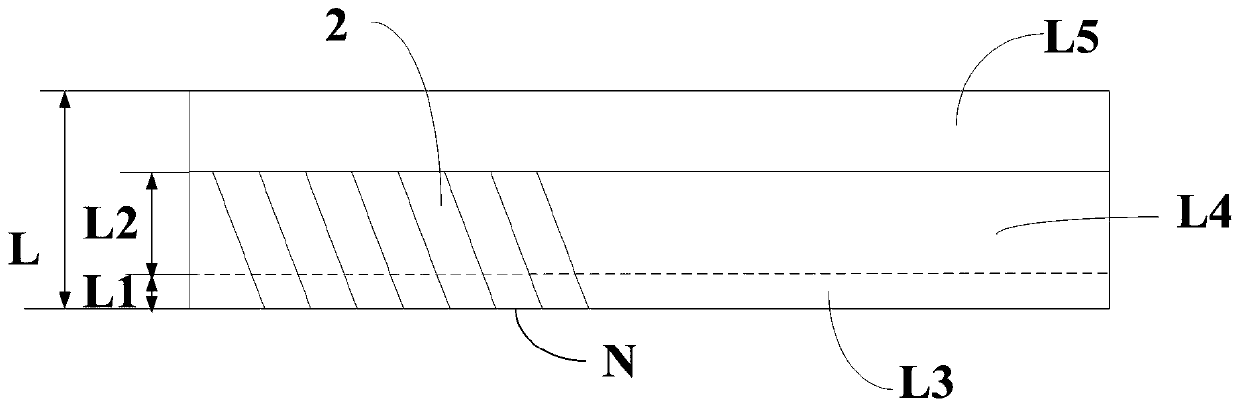

[0041] See attached Figure 2-3 , according to the characteristics of the hard coal pillar to be softened in this embodiment, the scheme for arranging blastholes is determined. According to the thickness L of the coal pillar 1, a row of blastholes 2 is arranged, and the blastholes 2 form an included angle of 60° with the length direction of the coal pillar 1. The width of the coal pillar to be softened is 20m, the length of the blast hole is selected to be 22m, and the diameter is 60mm. There is a certain distance from the reserved hard coal pillar area L5 that is not going to be recovered, and this plan chooses 1m. After comprehensively analyzing the strength and stability of the coal pillar, it is determined that the coal mine gas drainage water-gel explosive with a diameter of 50 mm (that is, a blasting charge made of a special grade 3 coal mine-approved water-gel explosive) is selected as the explosive, and the detonator is made of a mine-approved water-gel explosive. De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com