Intelligent foundation pit measurement system and method

A technology of intelligent measurement and foundation pit, which is applied in infrastructure engineering, infrastructure testing, construction, etc., can solve the problems of operational errors in measurement results, low precision, and backward efficiency of measurement technology, so as to improve accuracy and increase safety The effect of guarantee and smooth communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

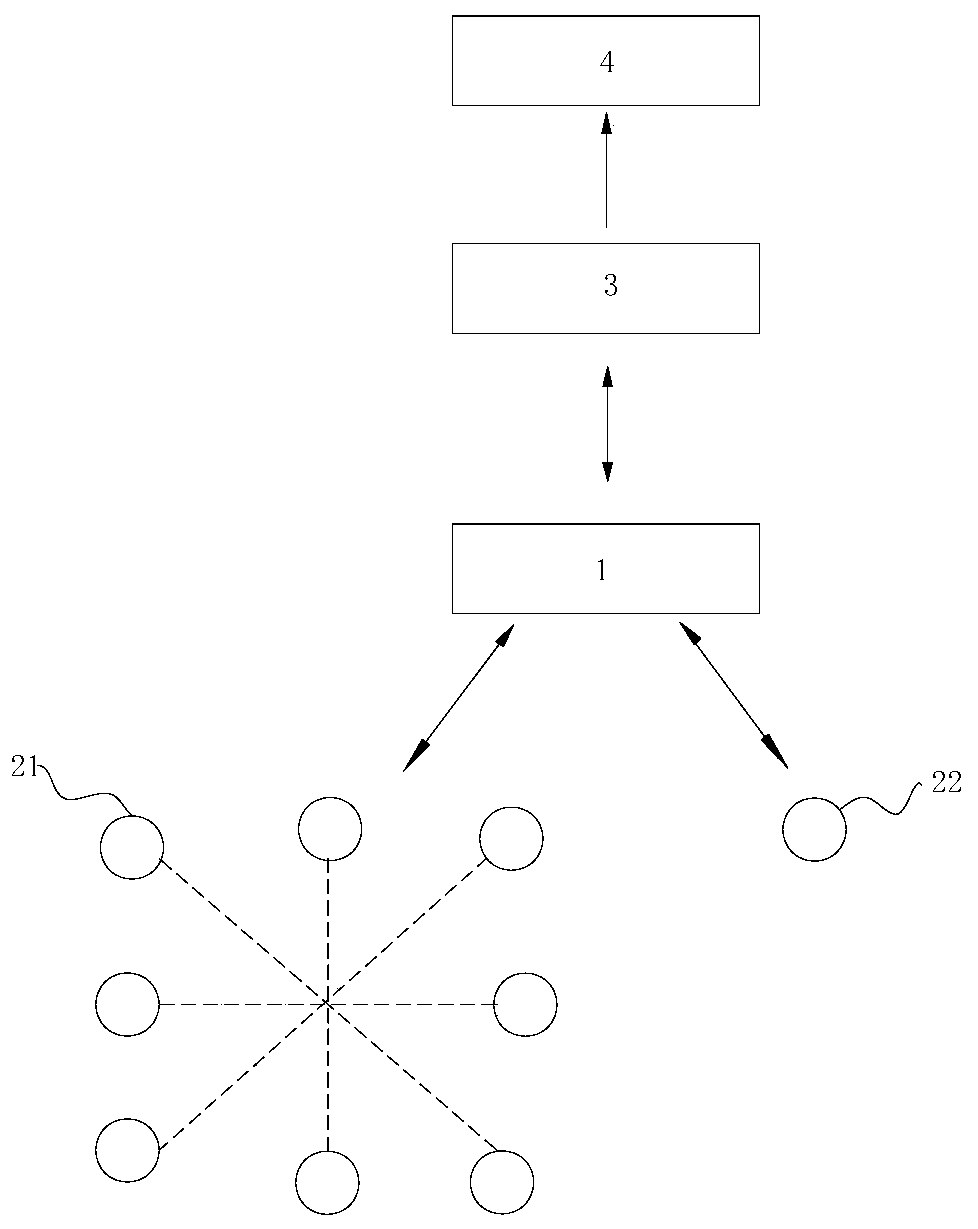

[0033] This embodiment provides a foundation pit intelligent measurement system, such as Figure 1-2 As shown, it includes a central processing unit 1 and at least 9 ranging units, all of which are communicatively connected to the central processing unit 1; wherein at least 8 ranging units are horizontal distance measuring units 21, and at least 1 ranging unit The distance unit is a vertical distance measurement unit 22 facing downward in the distance measurement direction; the central processing unit 1 is provided with a distance measurement terminal wireless communication module and a GPS positioning module; the distance measurement terminal wireless communication module is used for communicating with the intelligent mobile terminal Wireless 3 communication connection;

[0034] The intelligent mobile terminal 3 is connected to the central processing unit 1 by wireless communication, and is connected to the cloud data platform 4 by wireless communication, and it is equipped w...

Embodiment 2

[0044] This embodiment provides a method for utilizing the system described in Embodiment 1, including the following steps:

[0045] S1. Arrange each horizontal distance measuring unit and vertical distance measuring unit in the foundation pit to be measured, and establish a wireless connection between the central controller and the intelligent mobile terminal;

[0046] S2. Send a starting measurement signal to the central controller through the intelligent mobile terminal, and the central controller controls each distance measuring unit to start measurement;

[0047]S3. Each ranging unit transmits the foundation pit measurement data measured by itself to the central processor, and the central processor wirelessly transmits the foundation pit measurement data and the foundation pit geographic location information obtained by the GPS positioning module to the smart mobile terminal ;

[0048] S4. In the foundation pit intelligent measurement software in the intelligent mobile t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com