Carbon-based absorbing material, and preparation method and application thereof

An absorbing material and carbon-based technology, applied in the field of interface solar seawater desalination, can solve problems such as high requirements and complicated preparation process, and achieve the effects of improving utilization efficiency, accelerating evaporation efficiency, and improving light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a carbon-based absorbent material provided by the invention comprises the following steps:

[0028] Step 1, weighing biomass carbon powder, ethyl cellulose and stearic acid according to the mass ratio of 1:(1~2):(1~2);

[0029] Step 2, dissolving the biomass carbon powder, ethyl cellulose and stearic acid weighed in step 1 in an ethanol solvent to obtain a configured solution;

[0030] Step 3, heating and stirring the solution configured in step 2 to obtain a stirred solution, the mass concentration of which is 8-16 g / L;

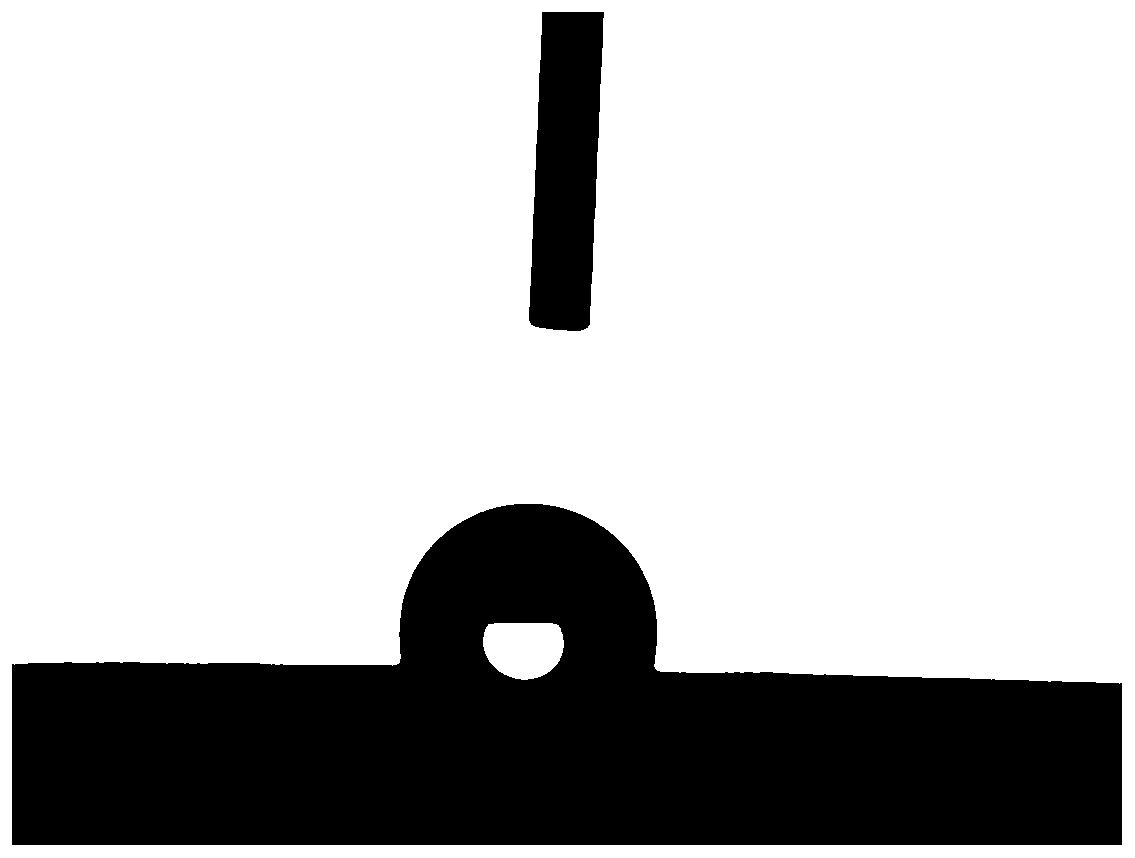

[0031] In step 4, the sponge is placed in the stirred solution obtained in step 3 by dip-dipping method to prepare a carbon-based absorbent material, and the carbon-based absorbent material is surface soaked, half soaked or completely soaked.

[0032] Wherein, in step 3, the technical conditions for heating and stirring the solution prepared in step 2 are: stirring at 250-350 r / min for 10-20 hours with a magnetic stirrer at a t...

Embodiment 1

[0038] A method for preparing a carbon-based absorbent material, comprising the steps of:

[0039] Step 1, weigh 0.4g of biomass carbon powder, 0.4g of ethyl cellulose and 0.4g of stearic acid;

[0040] Step 2, dissolving the biomass carbon powder, ethyl cellulose and stearic acid weighed in step 1 in 50ml of ethanol solvent to obtain a configured solution;

[0041] Step 3, stirring the solution prepared in step 2 at a temperature of 30° C. with a magnetic stirrer at 250 r / min for 10 h to obtain a stirred solution, the mass concentration of which is 10 g / L;

[0042] In step 4, the sponge is placed in the stirred solution obtained in step 3 by dip-dipping method to prepare a carbon-based absorbent material, and the carbon-based absorbent material is surface-immersed.

Embodiment 2

[0044] Step 1, weigh 0.2g biomass carbon powder, 0.4g ethylcellulose and 0.2g stearic acid;

[0045] Step 2, dissolving the biomass carbon powder, ethyl cellulose and stearic acid weighed in step 1 in 50ml of ethanol solvent to obtain a configured solution;

[0046] Step 3, stirring the solution prepared in step 2 at a temperature of 40° C. with a magnetic stirrer at 300 r / min for 13 hours to obtain a stirred solution with a mass concentration of 8 g / L;

[0047] In step 4, the sponge is placed in the stirred solution obtained in step 3 by dipping-dipping method to prepare a carbon-based absorbent material, and the carbon-based absorbent material is half soaked.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com