Operating and regenerating control method of one-stage ion demineralization equipment

A regeneration control and equipment technology, which is applied in the direction of ion exchange regeneration, ion exchange, water treatment parameter control, etc., can solve the problems of debugging, waste of operating materials, and low degree of automation, so as to save water production costs, operate flexibly and conveniently, and simplify The effect of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

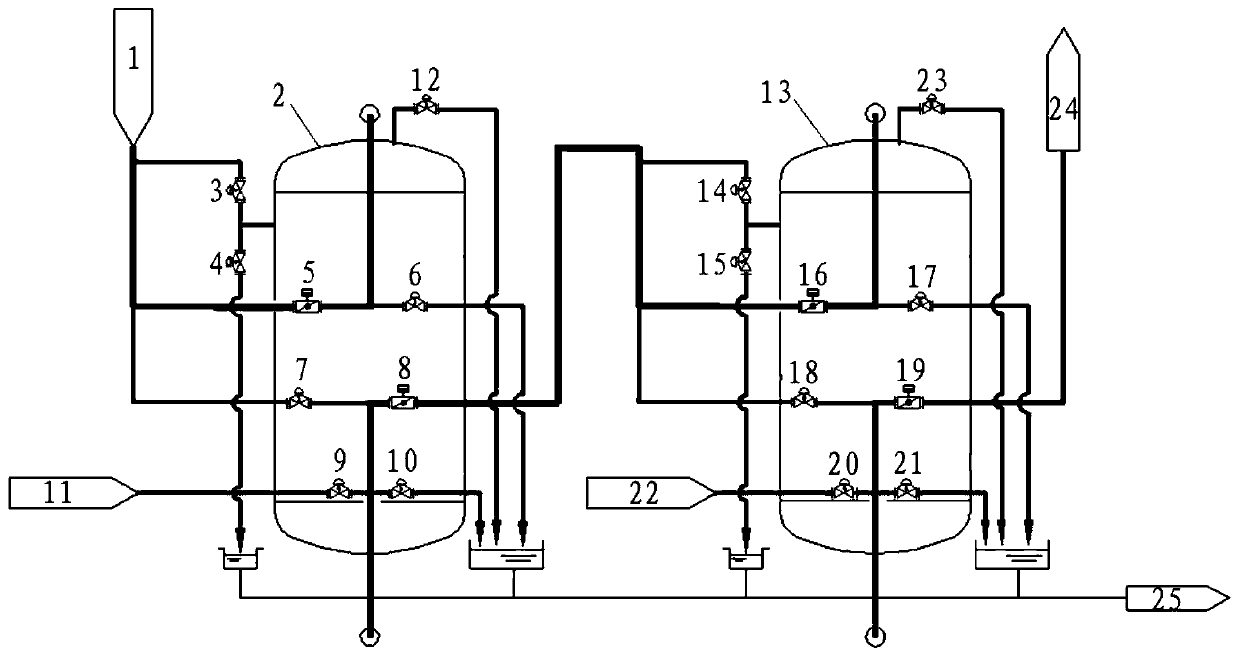

[0060] The operation and regeneration control method of a first-level ion desalting equipment provided by the present invention is used for the control of the first-level ion desalting equipment in the desalinated water production system of a nuclear power plant, and the first-level ion desalting equipment (such as figure 1 As shown) includes a first water inlet valve 5, a first water outlet valve 8, a first bottom drain valve 10, a first exhaust valve 12, a first large backwash water inlet valve 7, a first backwash drain valve 6 , the first middle drain valve 4, the first middle water inlet valve 3, and the positive bed 2 of the acid inlet valve 9 are provided with a second water inlet valve 16, a second water outlet valve 19, a second bottom drain valve 21, a second row Air valve 23, the second largest backwash water inlet valve 18, the second backwas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com