Lifting appliance equipment for nuclear power shielding factory building and installation method

A technology for shielding workshops and installation methods, applied in the directions of transportation and packaging, load hanging components, cranes, etc., can solve the problem that the nuclear power site does not have a large-scale assembly site, etc. The effect of the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

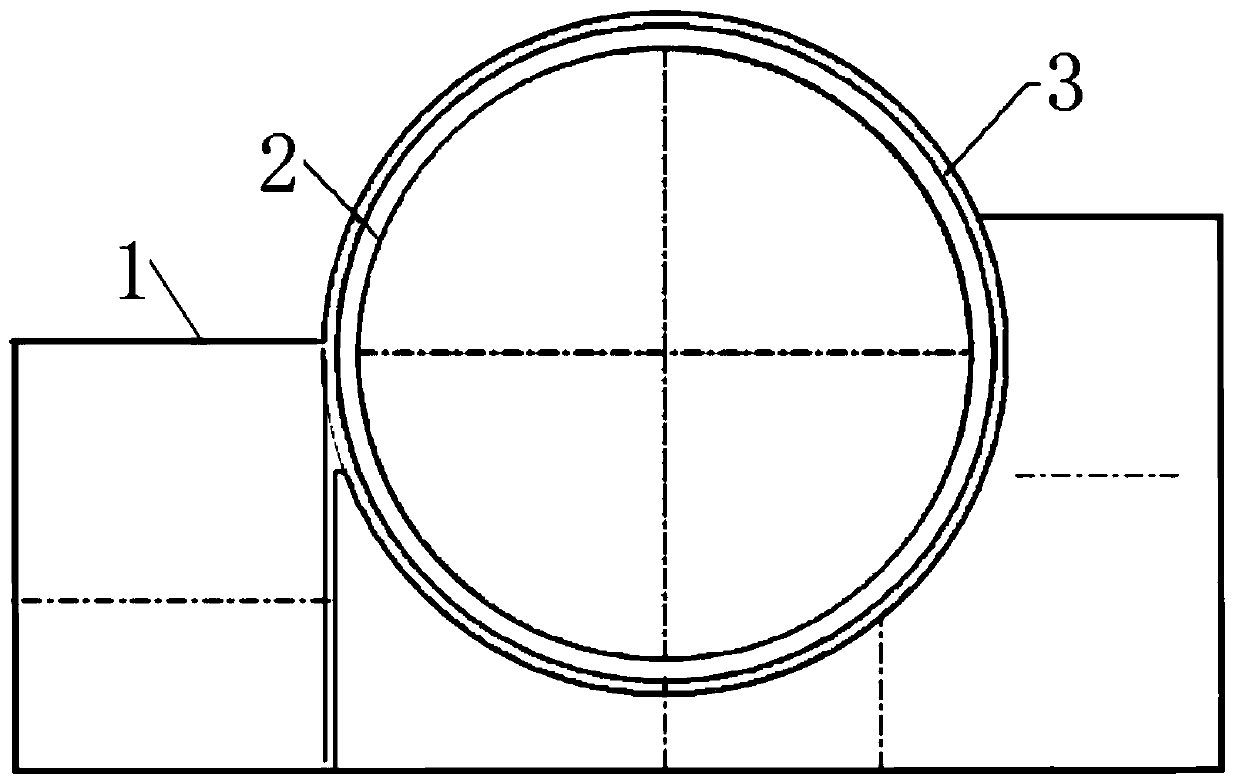

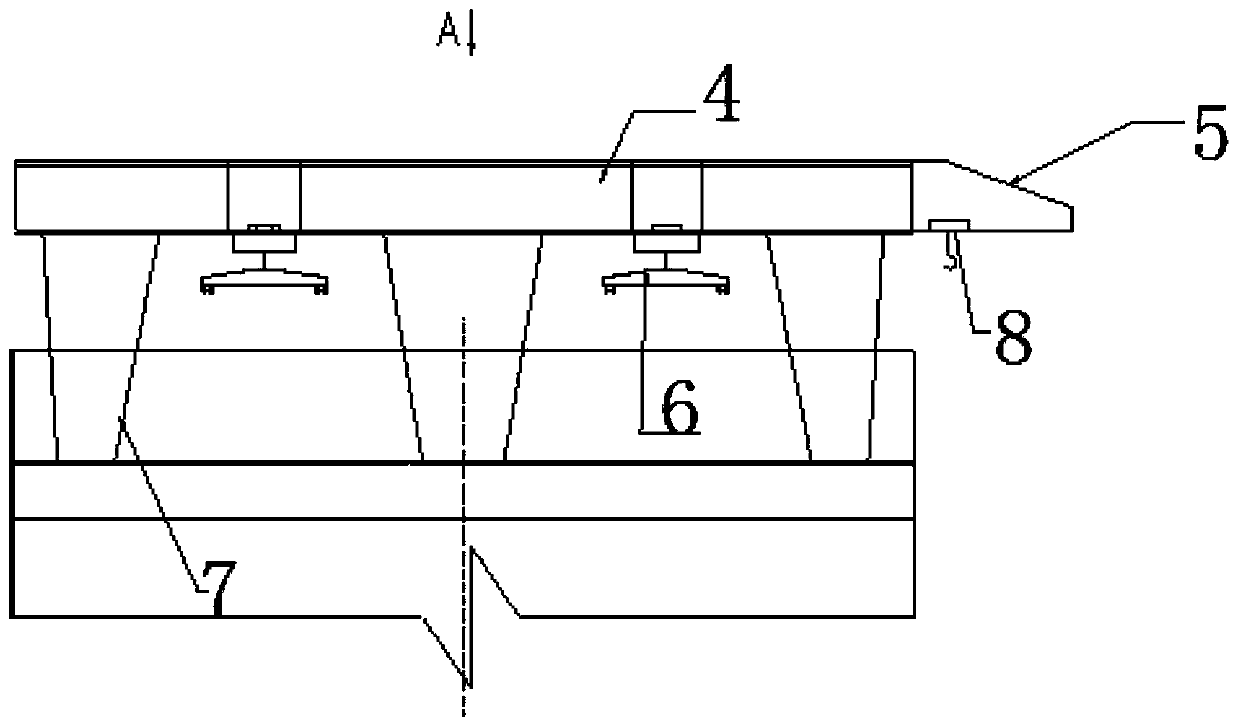

[0058] In a typical embodiment of the present invention, such as image 3 and Figure 4 As shown, the spreader equipment installed on the suspension beam of the steel containment ring is the first spreader, and the first spreader includes a ring-shaped first main structure 4, which is a truss structure, and the cross-section of the first main structure 4 It is rectangular, and the first main body structure 4 is supported by a plurality of legs. In this embodiment, the legs 7 are supported by steel containment ring suspension beams, and there are six legs 7, and the legs 7 are Trapezoidal truss structure, a 360° circular track 9 is provided on the outer side of the lower surface of the first main structure 4, and a number of rotary cantilevers 5 are arranged through the circular track 9, and the rotary cantilever 5 can run on the circular track 9 through the traveling mechanism and supporting wheels , The lower end surface of the rotary cantilever 5 is provided with an introdu...

Embodiment 2

[0066] The installation method of the shielded factory building includes the following contents:

[0067] 1) Installation of sub-modules below the steel containment cylinder elevation:

[0068] The shielding factory building is from 1 to 5 floors, and several assembled sub-modules on each floor ( Figure 7 The submodules numbered ①~⑥) are mainly within the range of 180°~360°, and are hoisted and installed by the first spreader, or according to the layered elevation position of the shielded workshop and the hoisting weight of the submodule, use a 30t~120t wheeled crane or Car cranes are hoisted and installed in place. According to the planning of the nuclear island hoisting area, the stations of cranes or truck cranes are distributed in the outer area of the containment building, such as Figure 7 shown;

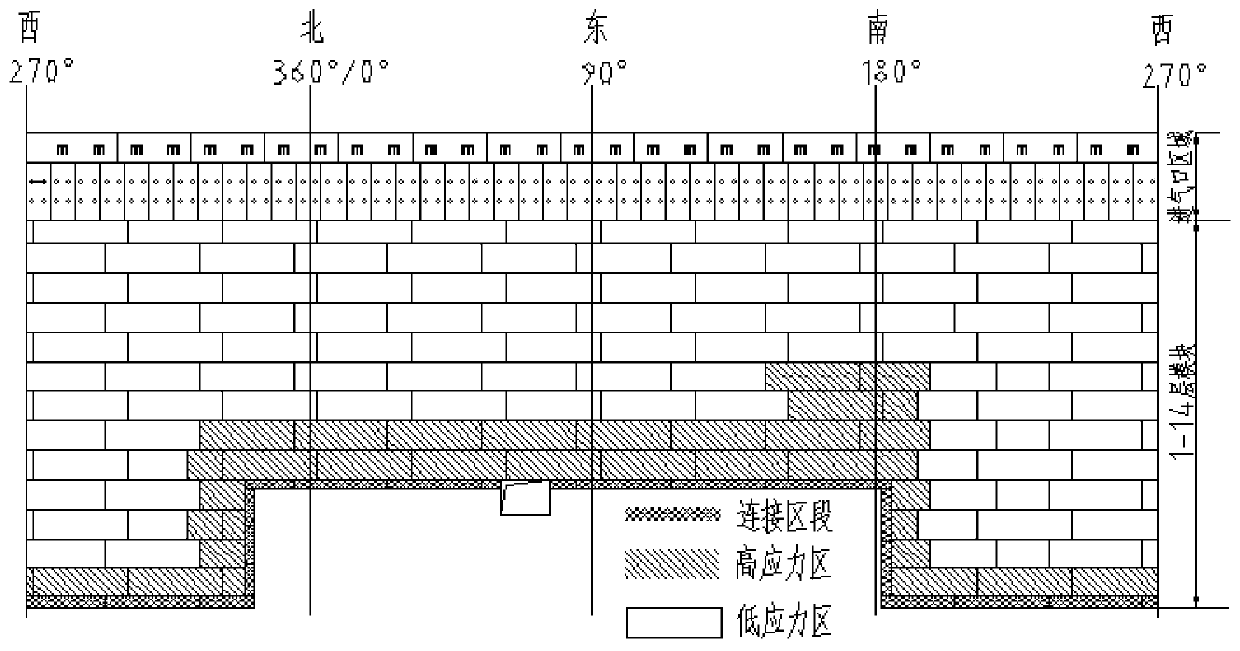

[0069] From the 6th floor to the 14th (m is greater than 2) floors, the sub-modules here are the whole ring structure, and the sub-modules distributed in the inner area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com