Construction site-spliced rigid node of frame beam and frame column for single-layer steel structure workshop

A steel structure and frame technology, which is applied in the direction of building structure and construction, can solve the problems of small on-site adjustment margin, and achieve the effects of avoiding high-altitude on-site welding, improving precision, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

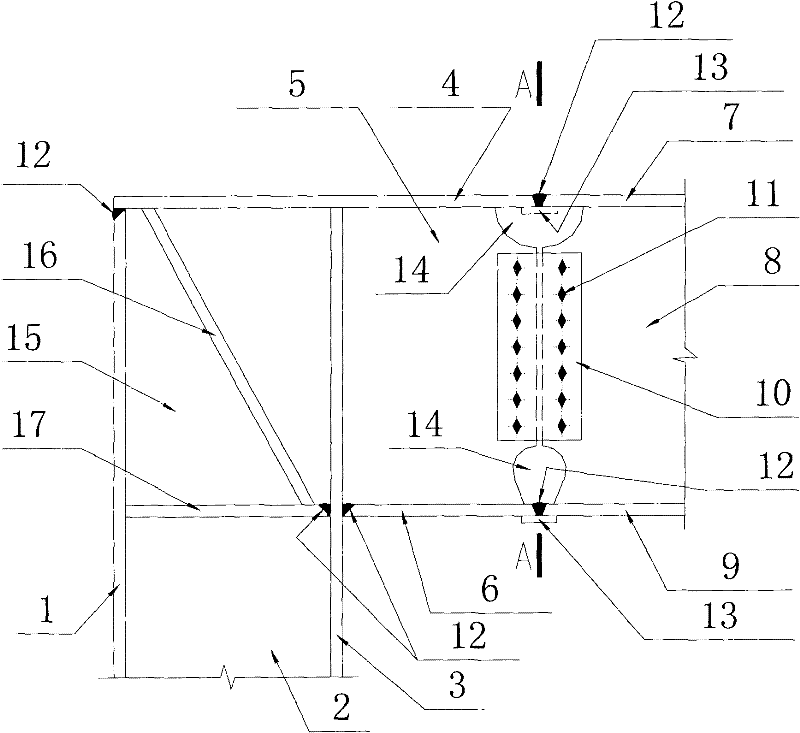

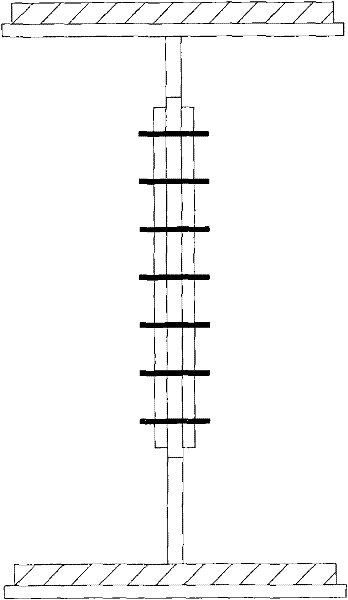

[0022] Embodiment one, as Figure 1-2 As shown, the frame beam-column rigid joints of a single-story steel structure factory building site include frame columns and frame beams, where the frame columns include outer column flanges 1, column webs 2, and inner column flanges 3; frame beams include cantilever beams section and middle beam section; the frame column is connected with a cantilever beam section, and the cantilever beam section includes the upper flange 4 of the cantilever beam section, the web plate 5 of the cantilever beam section, and the lower flange 6 of the cantilever beam section; the upper flange 4 of the cantilever beam section and the inner The column flange 3 and the top of the column web 2 are in contact with the outer column flange 1 with groove penetration welds; the lower flange 6 of the cantilever beam section is welded with the inner column flange 3 with groove penetration welds; The upper flange 4 of the cantilever beam section is welded to the upper ...

Embodiment 2

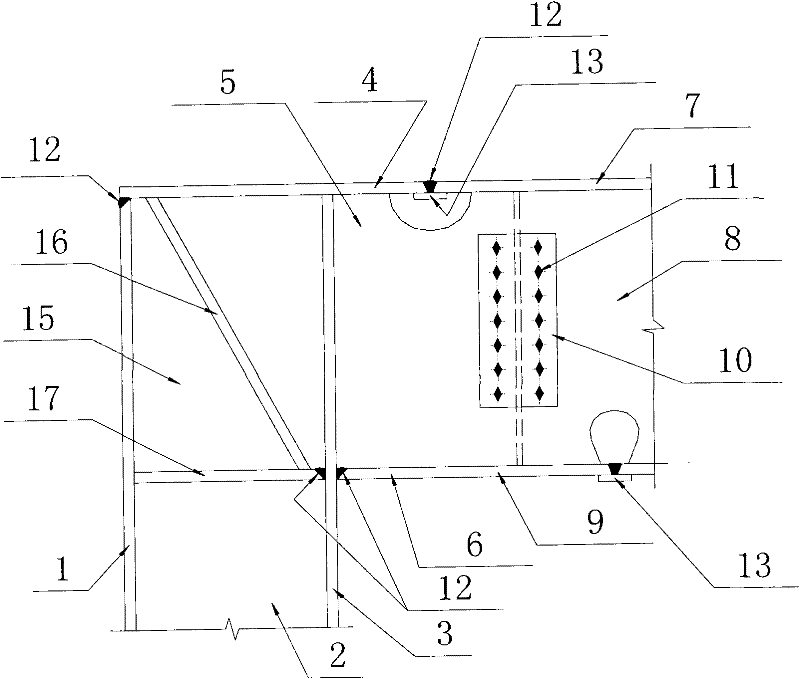

[0023] Embodiment two, such as image 3 As shown, the difference from Embodiment 1 lies in: the splicing seam between the upper flange of the cantilever beam section and the upper flange of the middle beam section, the splicing seam between the lower flange of the cantilever beam section and the lower flange of the middle beam section, and the web of the cantilever beam section The joints between the slab and the web of the middle beam section are not in the same vertical plane, and the extension length of the lower flange of the cantilever beam section from the flange of the inner column is greater than the extension length of the web of the cantilever beam section from the flange of the inner column , the extension length of the web of the cantilever beam section from the inner column flange is greater than that of the upper flange from the inner column flange.

Embodiment 3

[0024] Embodiment three, as Figure 4 As shown, the difference from Embodiment 1 is that the cantilever beam section and the middle beam section are inclined: the cantilever beam section and the middle beam section are inclined upward along the mid-span direction to facilitate drainage; or the cantilever beam section and the middle beam section are downward along the mid-span direction Inclined to form a single slope roof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com