Numerical control drilling, tapping and milling integrated machining equipment with central through hole for water outlet

A center through hole, processing equipment technology, applied in metal processing equipment, metal processing mechanical parts, other manufacturing equipment/tools, etc., can solve the problem of the column gravity center being biased to one side of the shaft head, affecting the accuracy of the workpiece, poor equipment stability, etc. Achieve the effect of improving transmission efficiency, improving mute effect and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

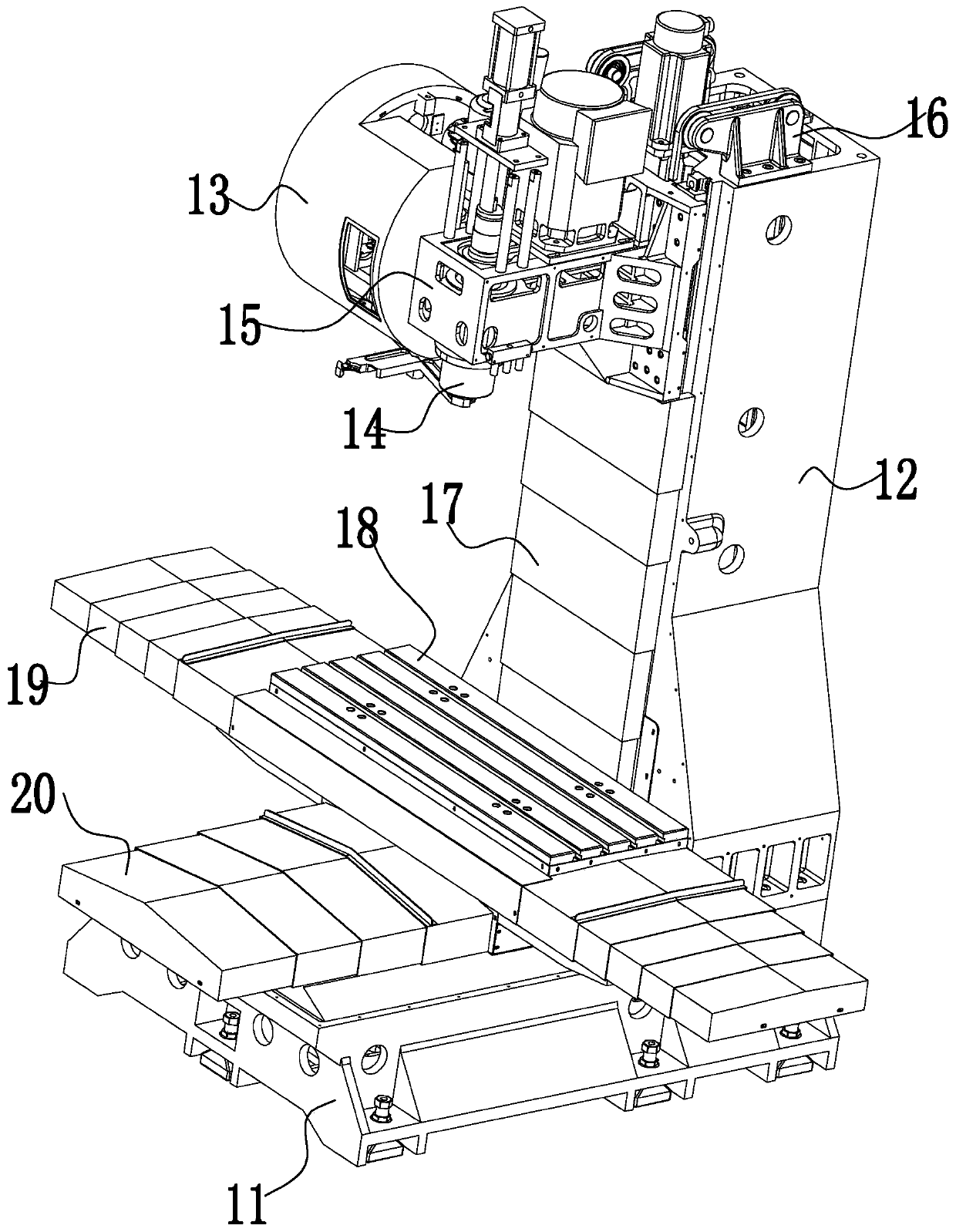

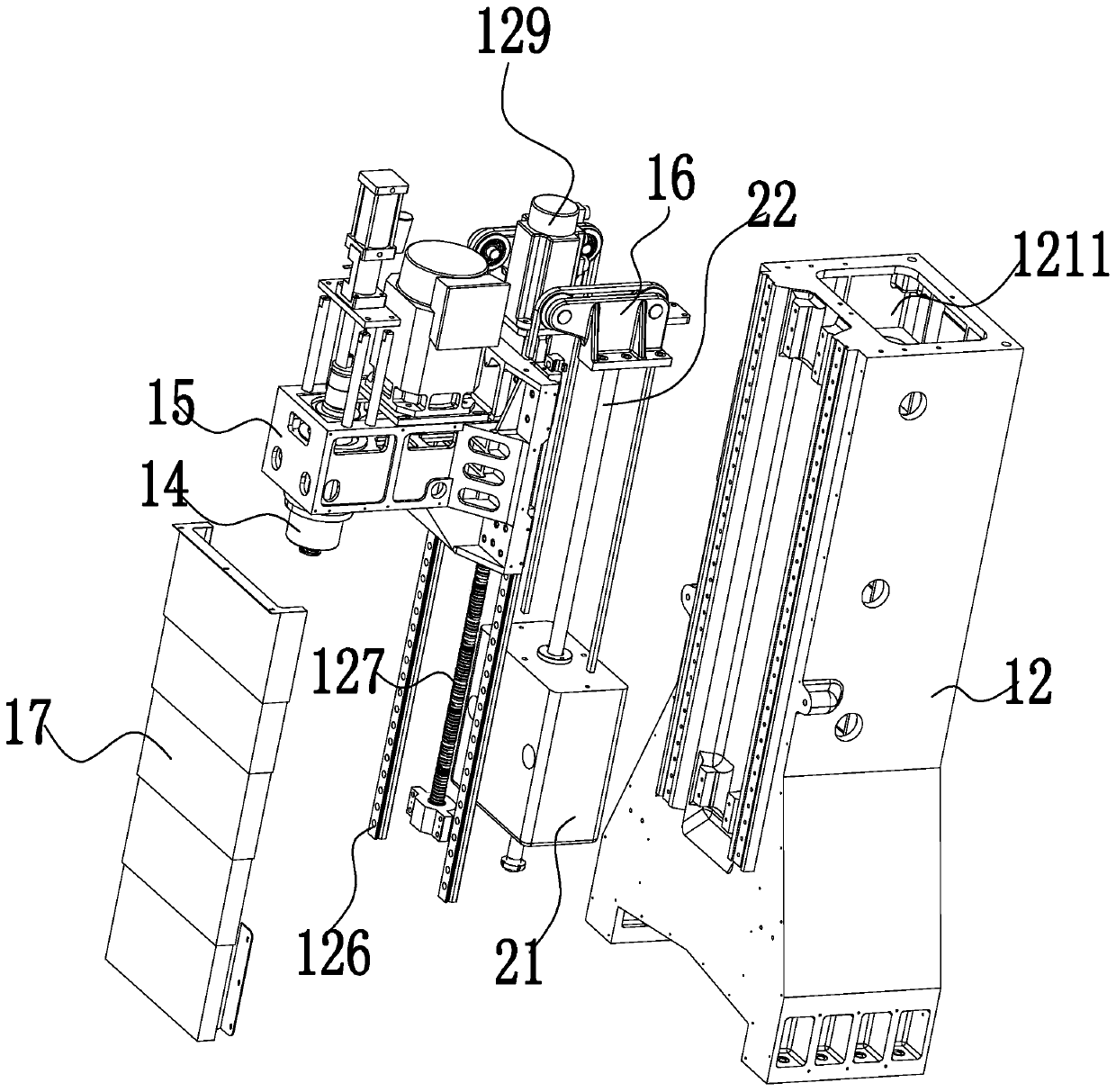

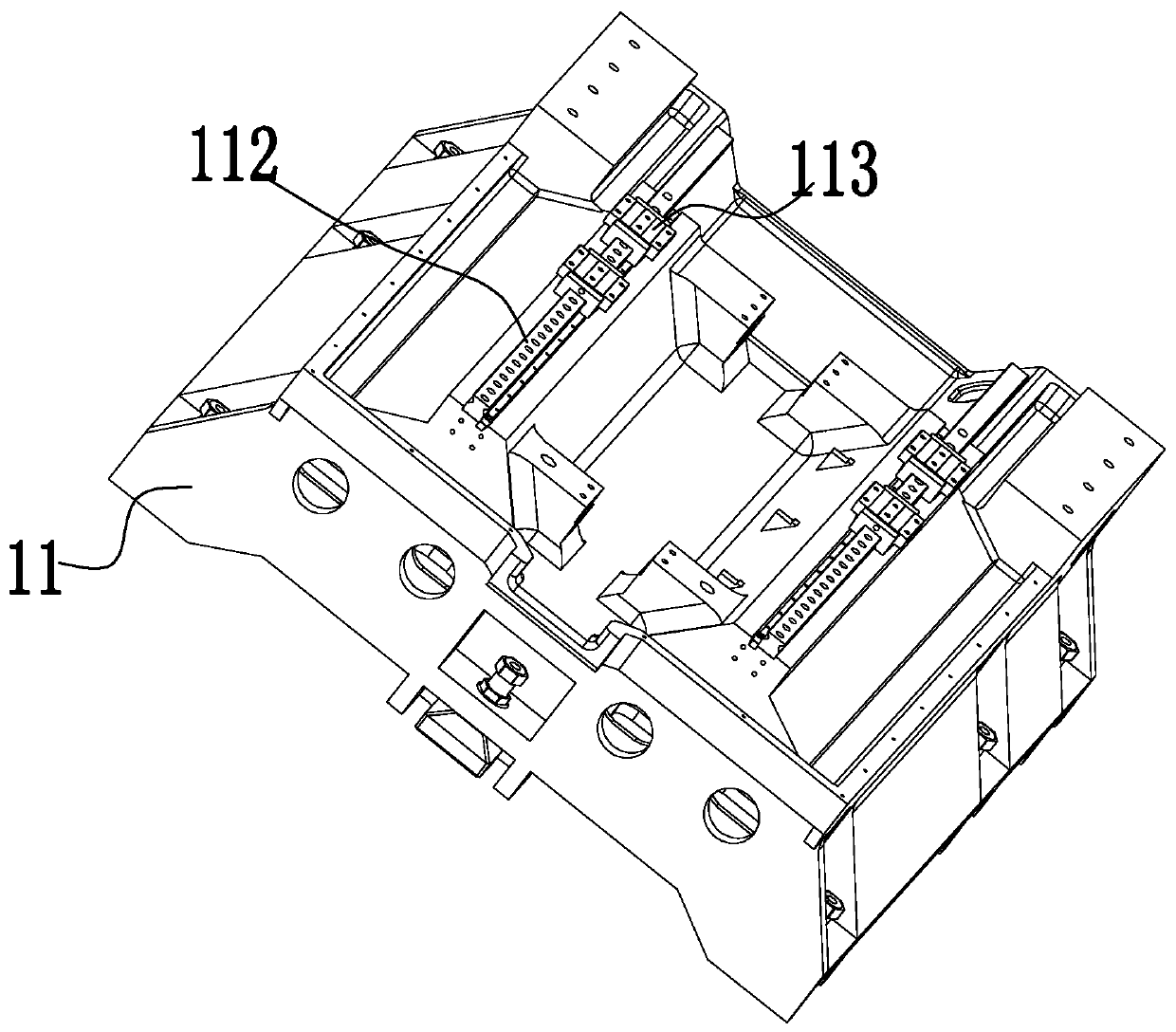

[0047] refer to figure 1 , Figure 4 , the embodiment of the present invention discloses a CNC drilling, tapping and milling integrated processing equipment with a central through hole for water outlet, including a frame, the frame is provided with a base 11, a horizontal frame 23 and a stand 12, and the base 11 is along the Its length direction is set as the Y direction, the base 11 is set as the X direction along its width direction, and the base 11 is set as the Z direction along its height direction, and the base 11 is fixedly installed with two A parallel slide rail 112, a first slide block 113 is slidably arranged on the first parallel slide rail 112, and the horizontal frame 23 is slidably installed on the base 11 along the Y direction through the first slide block 113, the The base 11 is located between the two first parallel slide rails 112 and is provided with a first installation groove. A first screw mandrel 114 is mounted on the bearing for rotation, and a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com