Production and manufacturing method of bearing

A manufacturing method and bearing production technology, applied in the direction of manufacturing tools, maintenance and safety accessories, coatings, etc., can solve the problems of failure to collect lubricating oil, low manual operation efficiency, poor lubrication effect, etc., to reduce labor input, Reduce the coefficient of friction, the effect of good factory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

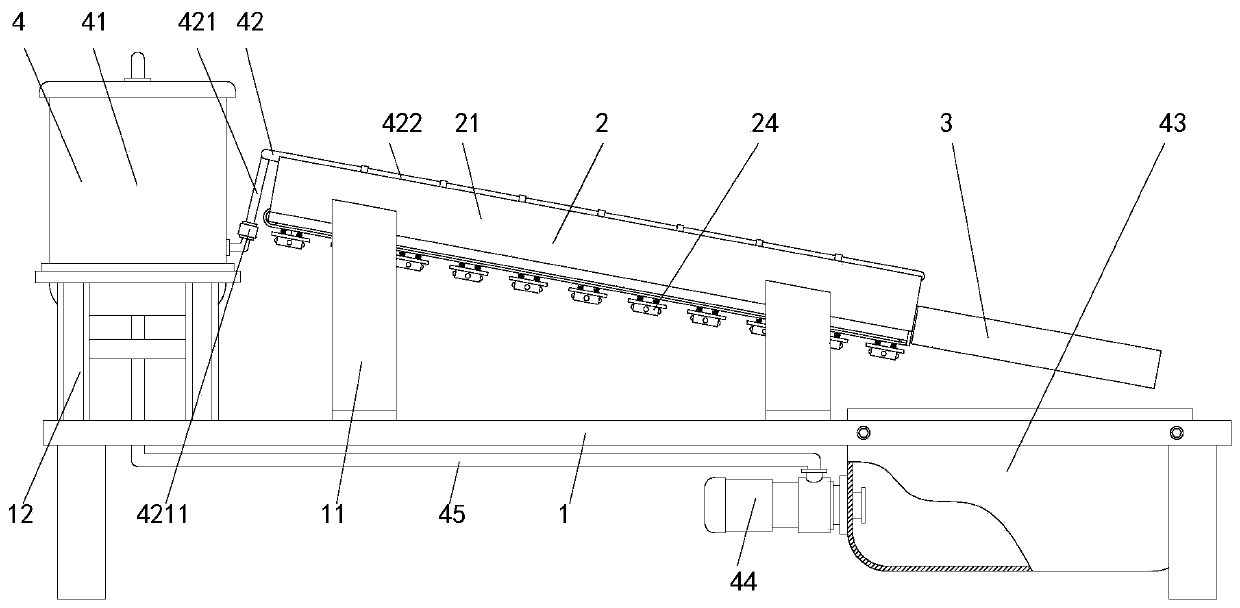

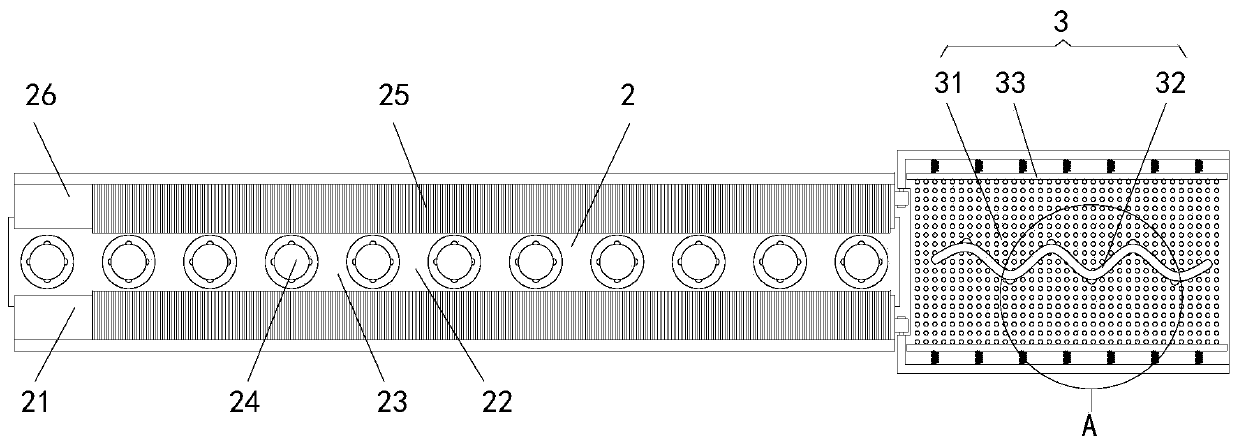

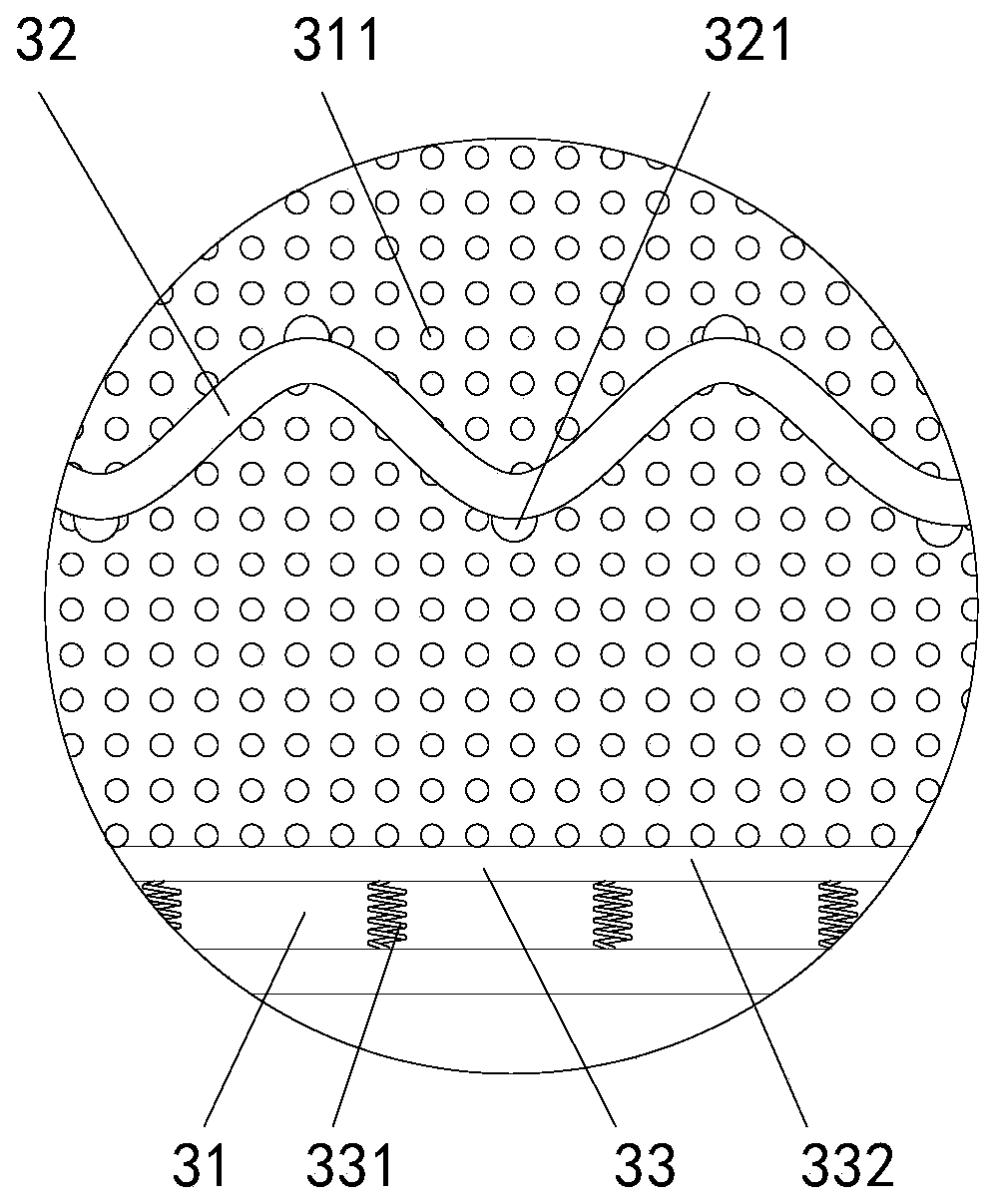

[0034] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

[0035] like Figure 1 to Figure 6 As shown, a bearing production and manufacturing method provided by the present invention specifically includes the following steps:

[0036] S1. Clean the surface of the bearing outer ring, bearing inner ring, cage and rollers processed by machining to remove dust, metal filings, stickies, etc. on the surface;

[0037]S2. Assemble the bearing outer ring, bearing inner ring, cage and rollers in step S1 to obtain a finished bearing;

[0038] S3. Manually place the finished bearings in step S1 into the limiter assembly 24 on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com