Cleaning frame sheet inserting mechanism and cleaning mechanism

A technology of cleaning mechanism and cleaning rack, which is applied in the directions of cleaning flexible articles, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effect of improving operation accuracy and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

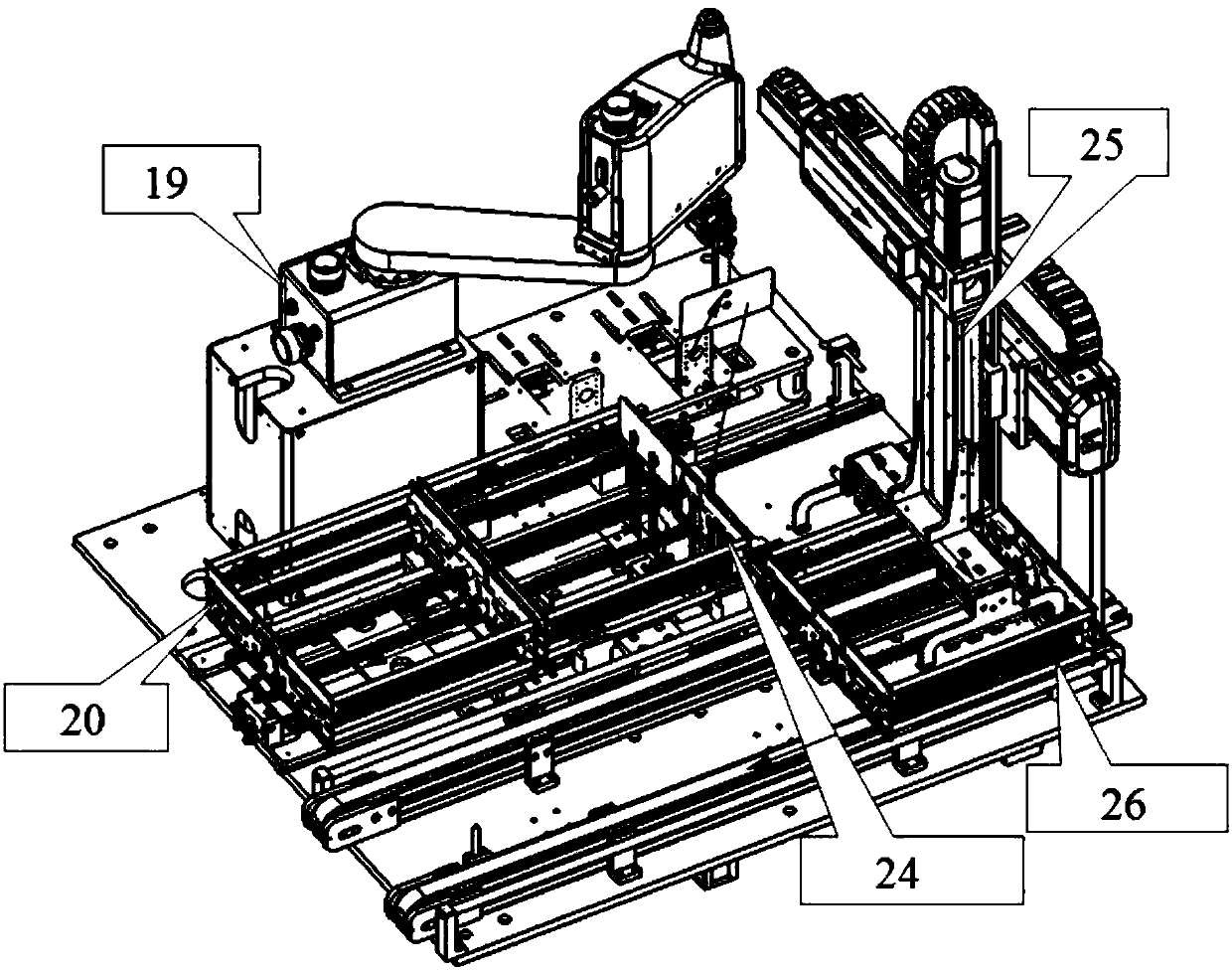

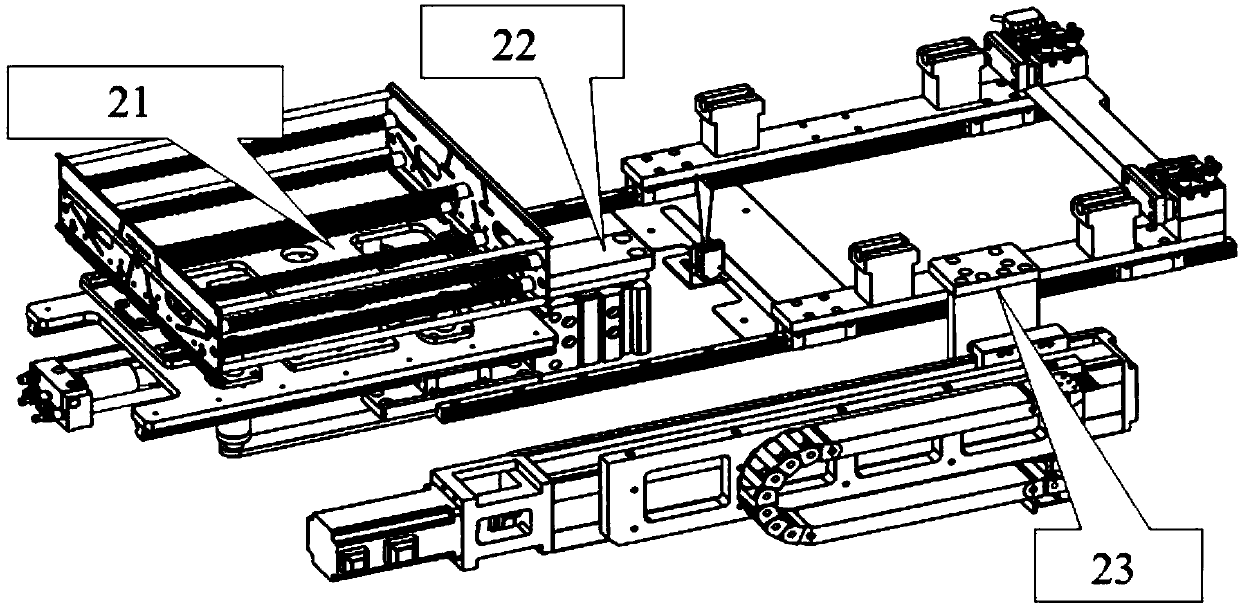

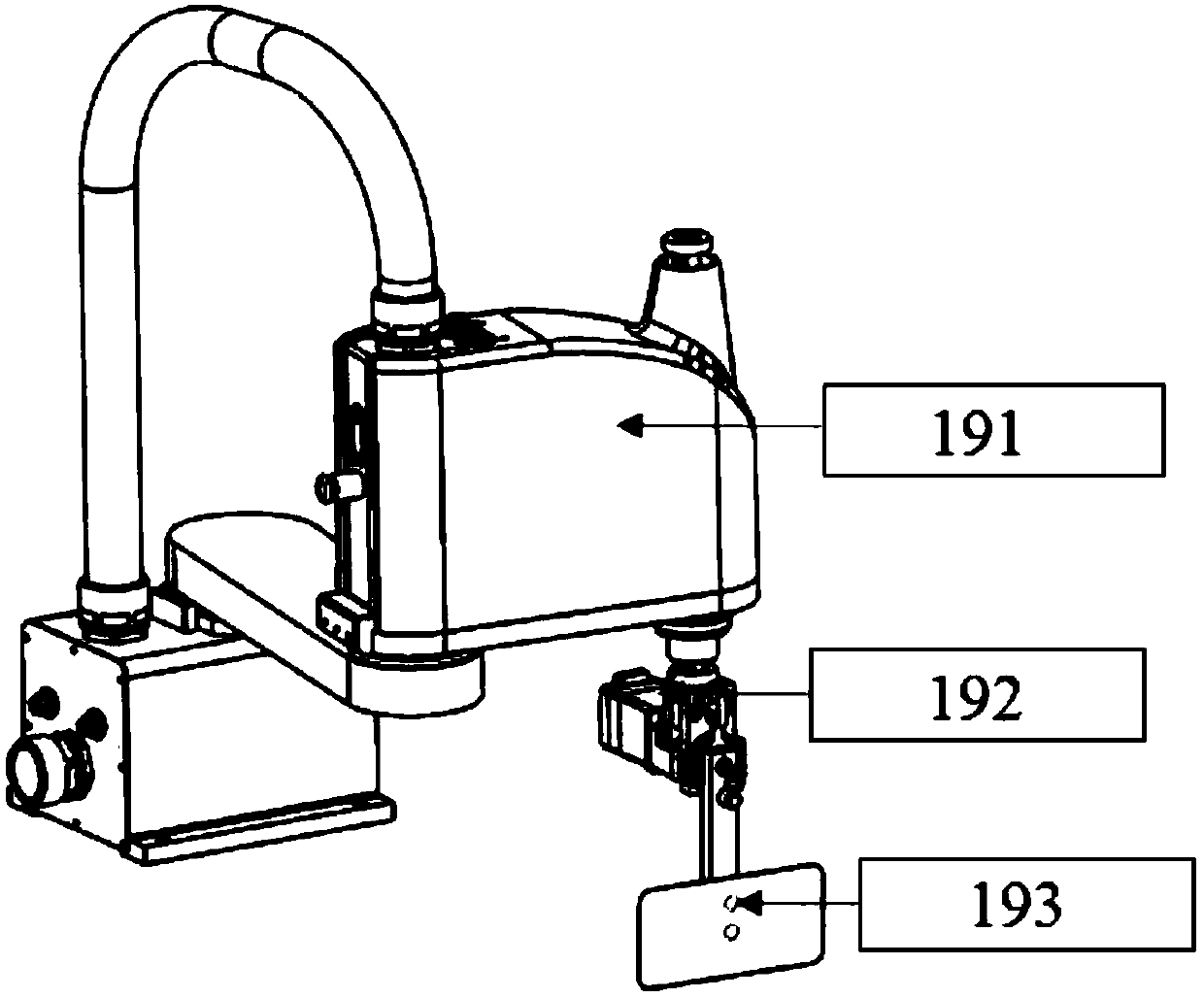

[0049] The specific implementation method is: the cleaning frame 20 transplanting mechanism 25 and the return belt line 26 are fixed on the equipment table panel through the support plate 251 and the bracket 261; after the cleaning frame 20 inserts the operation, the X-direction transplanting module 252 moves to the left Position above it, grab slide table cylinder 253 to open, Z direction transplanting module 254 descends, clamped by jaws 255. The Z-direction transplanting module 254 rises, and the X-direction transplanting module 252 shifts to the top of the 26 return belt lines to the right; Group 254 goes down, puts cleaning frame 20 on conveyor belt 263, grabs slide table cylinder 253 and opens, and the cleaning frame 20 completed by inserting frame returns to the position to be recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com