A multi-functional dipping machine for preparing nylon 6 cord fabric based on the principle of split-vibration flat-combing

A cord fabric, multi-functional technology, applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems such as the inability to guarantee the smoothness of the coating, the uneven distribution of the glue, and the easy occurrence of cracked glue, etc. Achieve the effect of realizing shock separation, improving permeability and improving stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

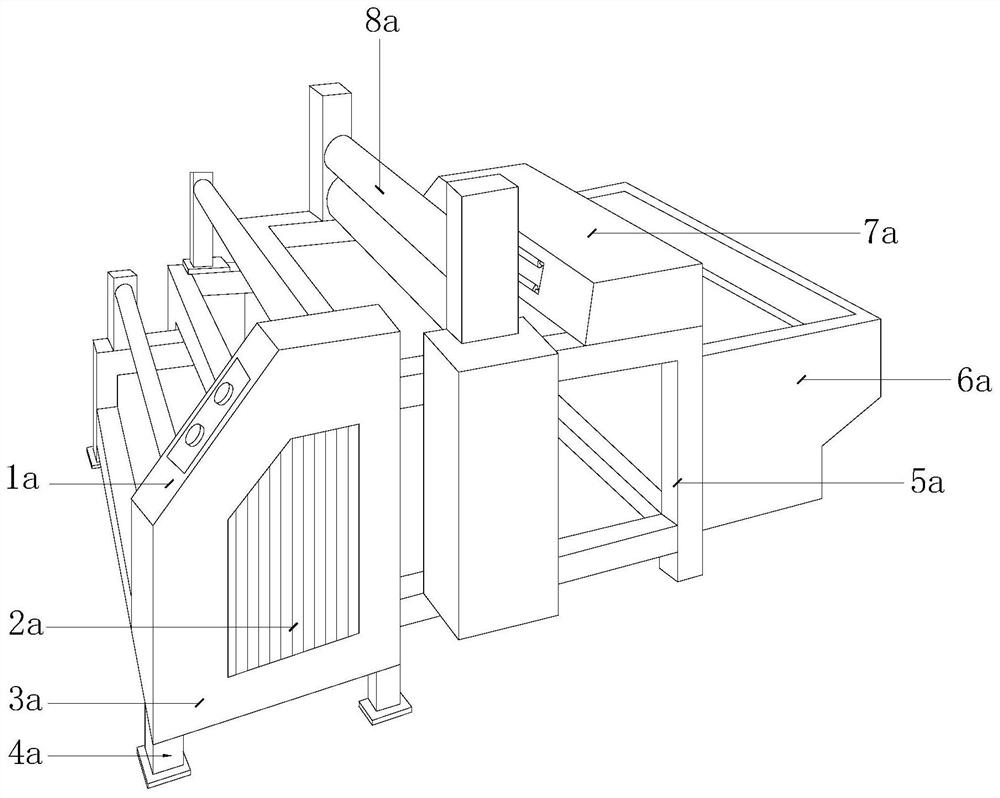

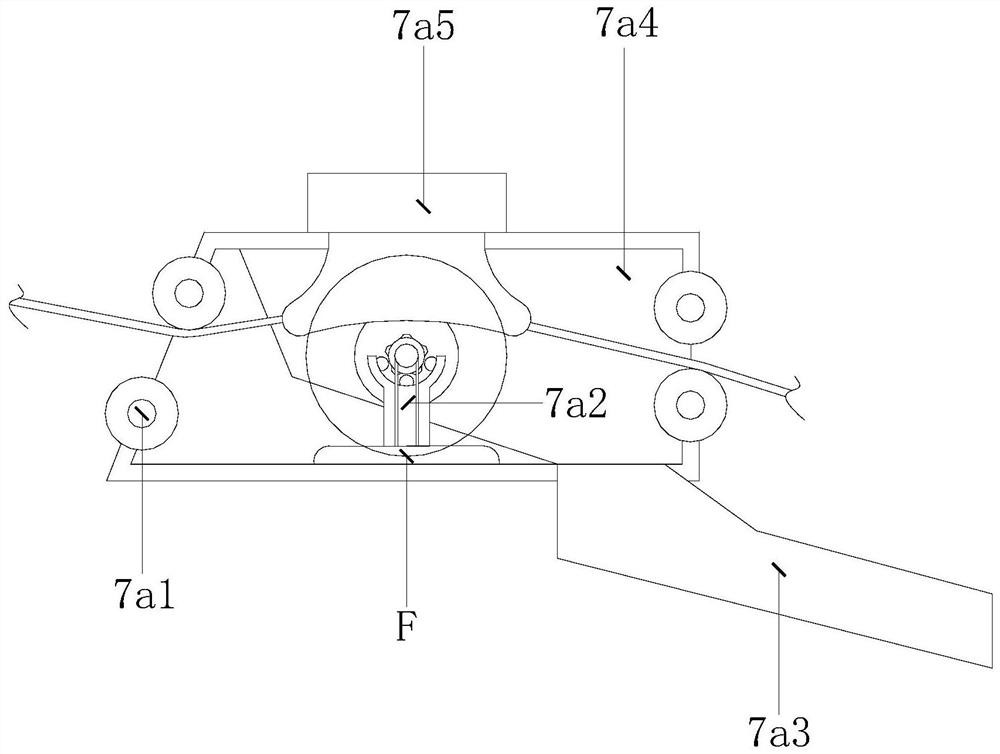

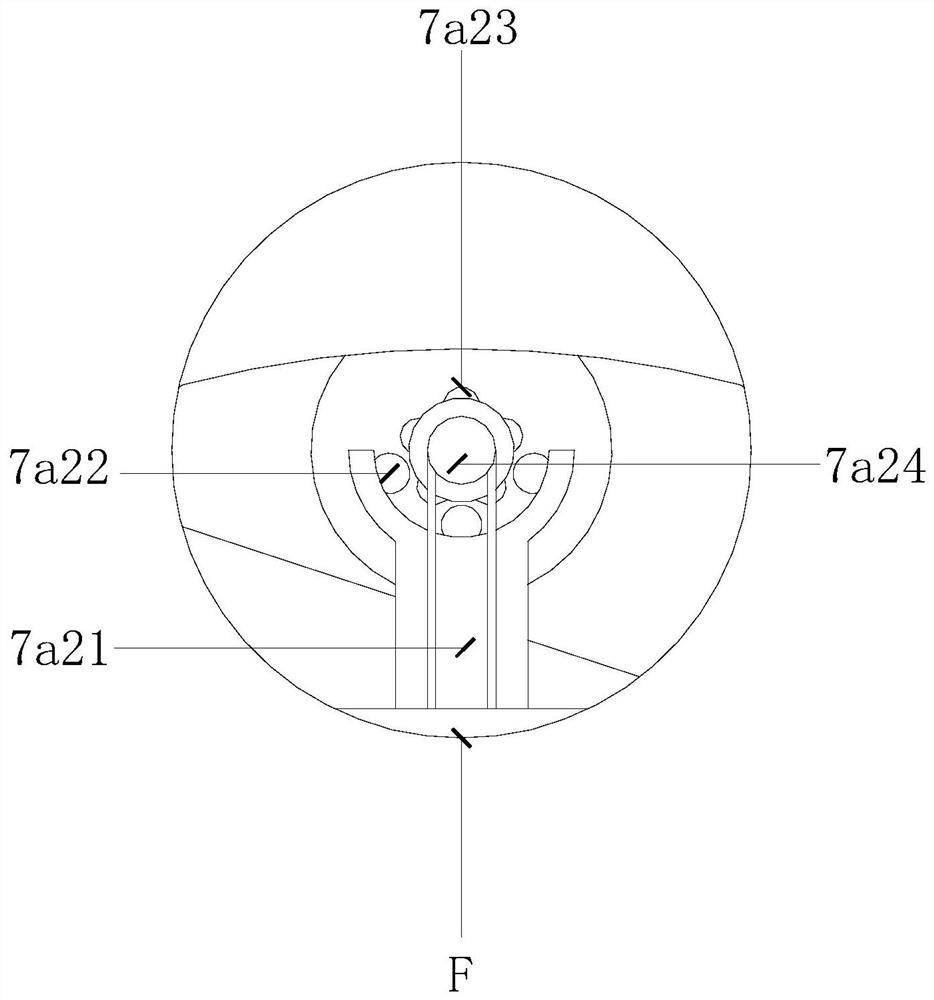

[0029] see Figure 1-Figure 6 , the present invention provides a multifunctional dipping machine for preparing nylon 6 cord fabric based on the principle of split-vibration flat combing, the structure of which includes a control panel 1a, a cooling tank 2a, a main device 3a, fixed feet 4a, a mounting frame 5a, and a dipping bin 6a , flat comb mechanism 7a, intermediate shaft 8a, the fixed feet 4a are provided with four, and are evenly and equidistantly installed on the bottom of the equipment host 3a, and the right side of the equipment host 3a is provided with a cooling groove 2a, which is integrated structure, the control panel 1a is installed on the top of the right end of the main equipment 3a by embedding, the front end of the installation frame 5a is fastened with the middle part of the control panel 1a, and the dipping chamber 6a is arranged on the rear end of the installation frame 5a by fitting , the rear end of the top of the mounting frame 5a is provided with a flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com