Motor rotor permanent magnet attachment system

A technology for motor rotors and permanent magnets, applied in the manufacture of stator/rotor bodies, motor generators, electrical components, etc., can solve the problems of high labor costs, high technical level and proficiency requirements, and low production efficiency, and achieve Save labor cost, improve pasting effect and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

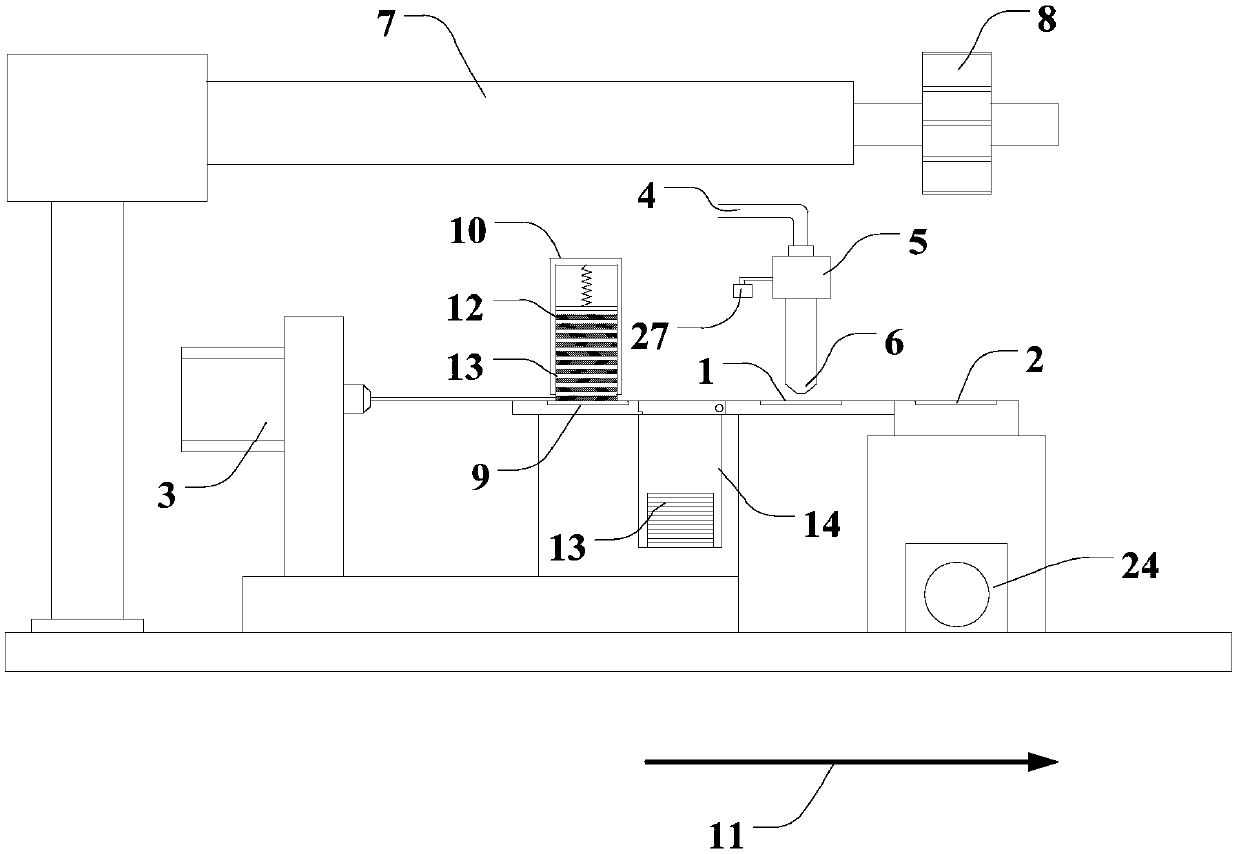

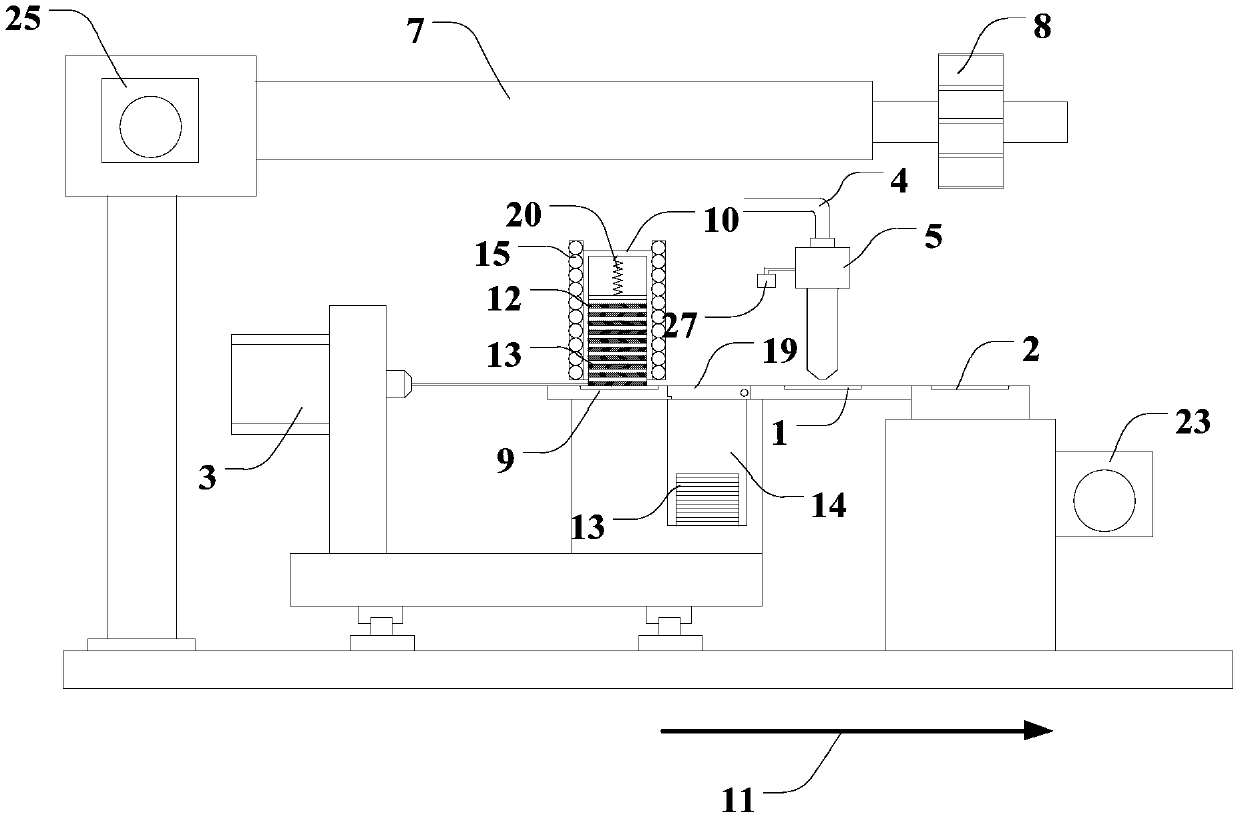

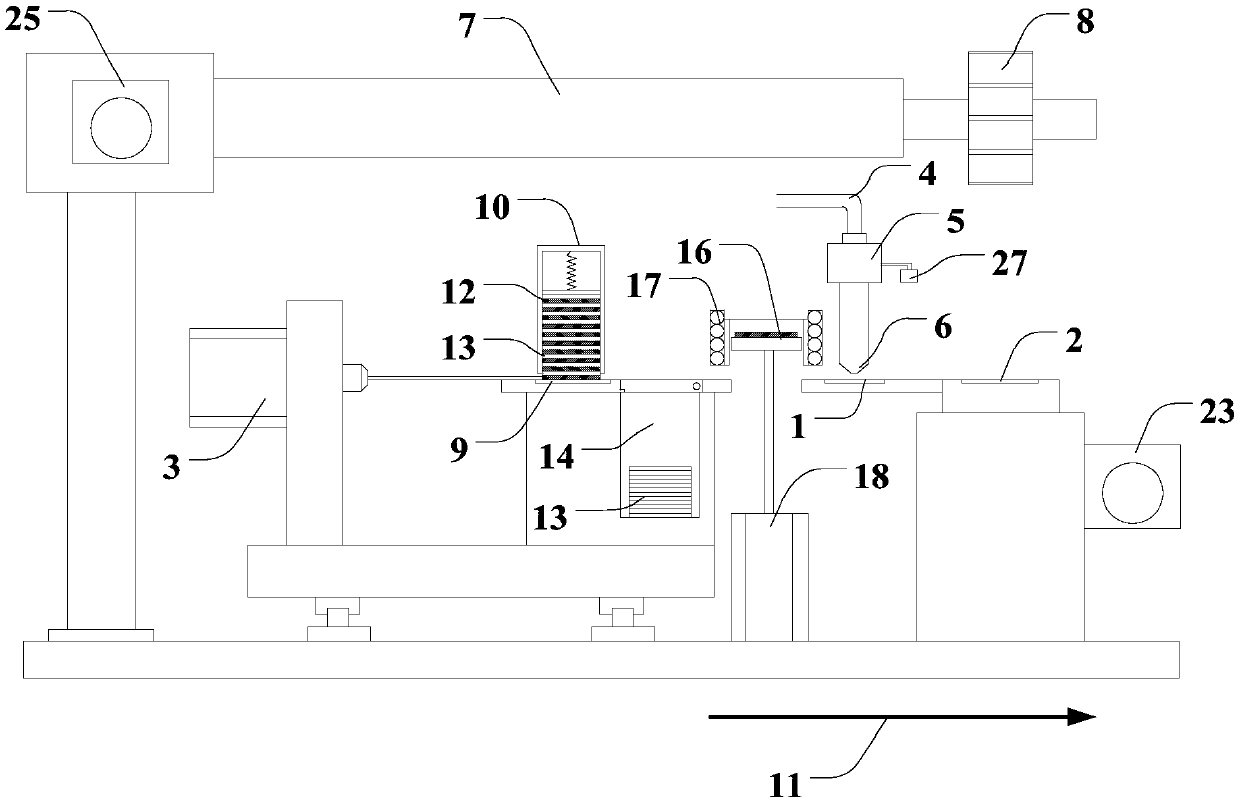

[0065] When making a motor, it is necessary to attach permanent magnets to the surface of the motor rotor. In the prior art, manual attachment is usually used, or semi-automatic mechanical equipment and manual cooperation are used to attach permanent magnets to the motor rotor. In the prior art, the process of attaching the magnetized permanent magnet to the rotor has high requirements for operators, high labor costs, and low production efficiency. The invention provides a motor rotor permanent magnet attaching system that can work fully automatically. The system at least includes a gluing station and a sticking station, as well as a permanent magnet pushing device, a gluing device and a rotor installation device. After the permanent magnet arrives at the gluing station, the gluing device applies glue on the surface of the permanent magnet, and then the permanent magnet pushing device pushes the glued permanent magnet to the pasting station, where the permanent magnet is paste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com