Plug-in connector for differential data transmission

A plug-in connector and differential data technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems that cannot be applied to products with small external dimensions, cannot meet the processing requirements of parts, and have harsh processing technology, etc. problems, to achieve the effect of eliminating short stub effect, improving signal quality, and improving signal crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

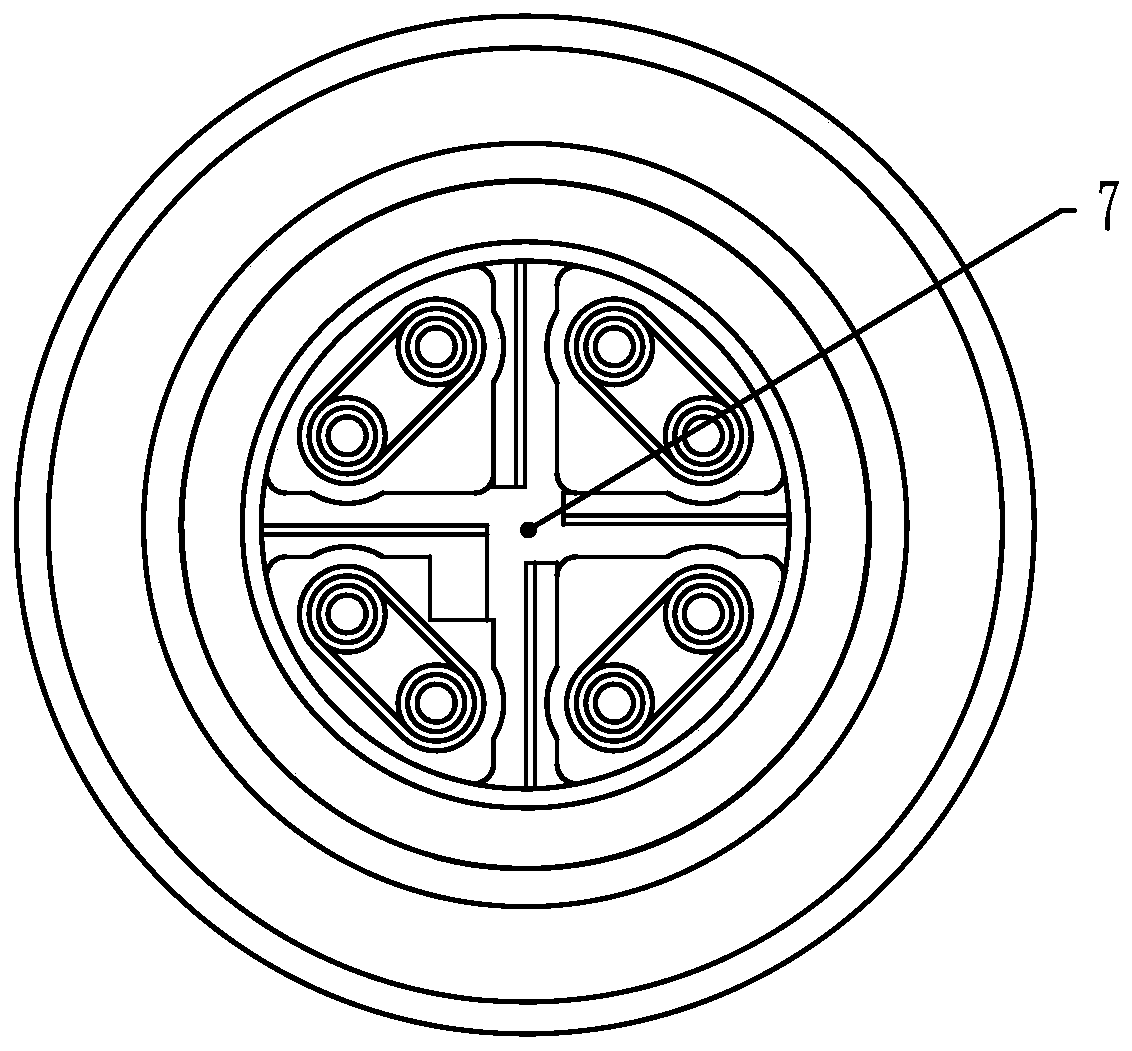

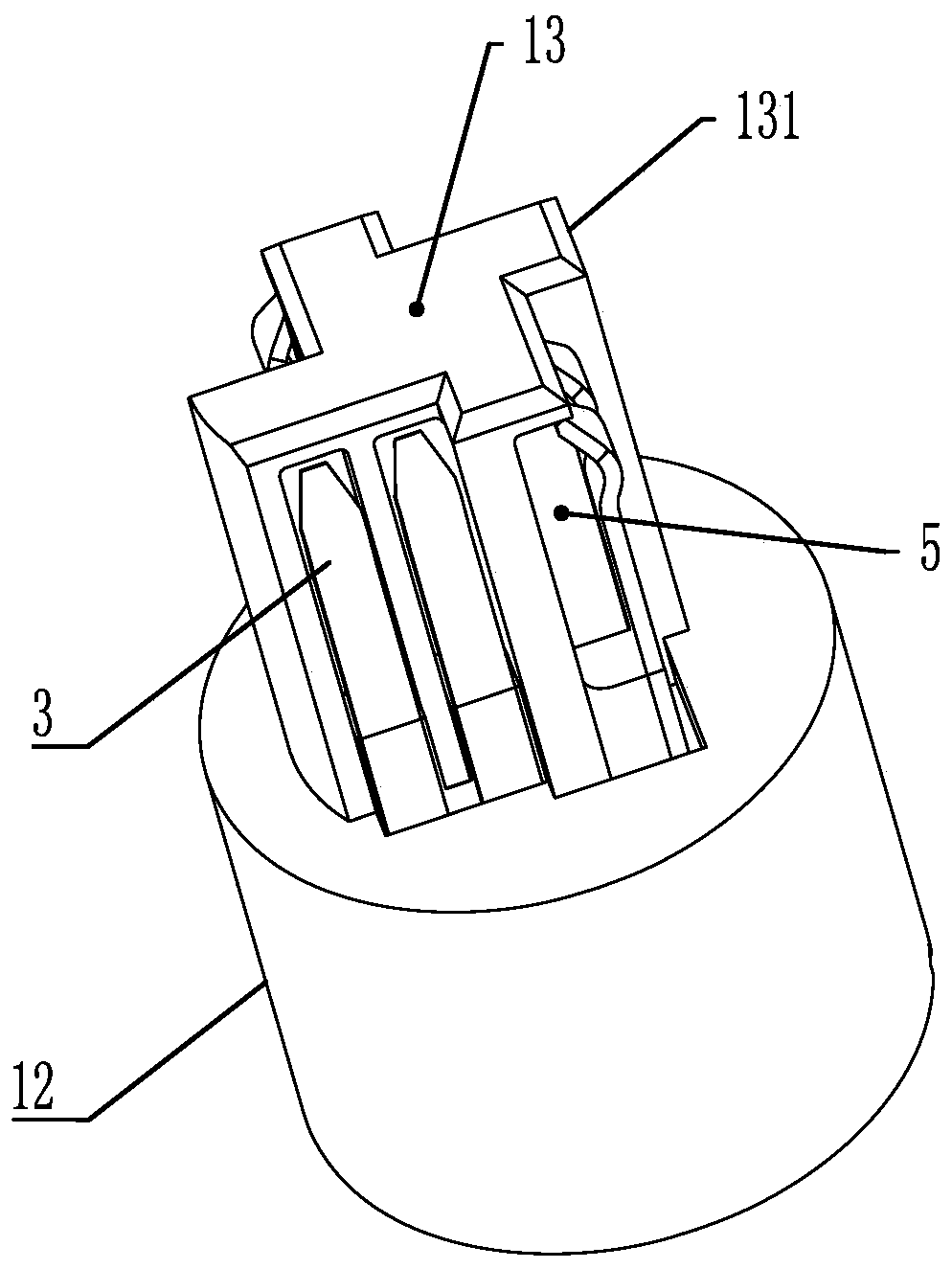

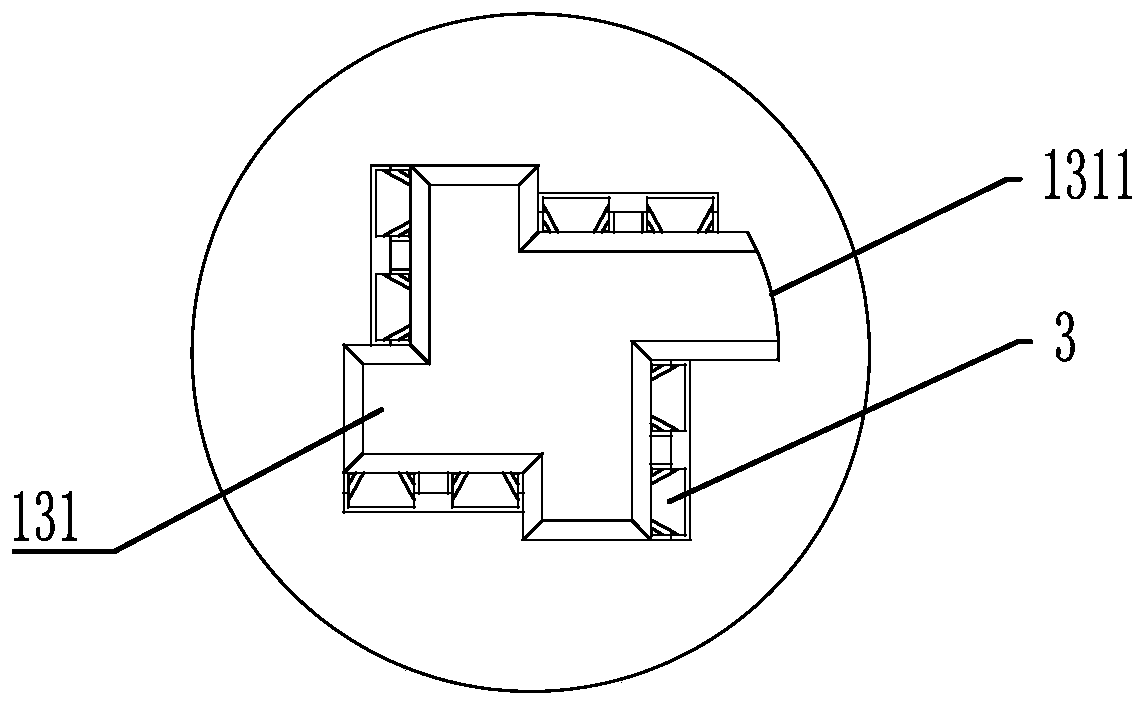

[0027] A specific embodiment of a plug connector for differential data transmission proposed by the present invention: as Figure 2 to Figure 7 As shown, it includes a plug connector and a socket connector for matching use. The plug connector includes a plug tail sleeve 12 installed in the plug housing 11 and a plug tail sleeve 12 installed in the plug tail sleeve 12 and protruding from the top of the plug tail sleeve. The plug insulator 13, the plug insulator 13 has four axially arranged protrusions 131 along the circumferential direction, so that the entire plug insulator is similar to a windmill shape, the circumferentially adjacent protrusions are perpendicular to each other, and the same side of each protrusion 131 is provided with parallel The plug blade contacts 3 are arranged, and the plug blade con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com