An inner mold splicing module and a variable detachable inner mold and its construction technology

An internal mold, variable technology, used in construction, bridge construction, bridges, etc., can solve problems such as hidden quality problems, irregular deformation of concrete molding, and small internal space for steel internal molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

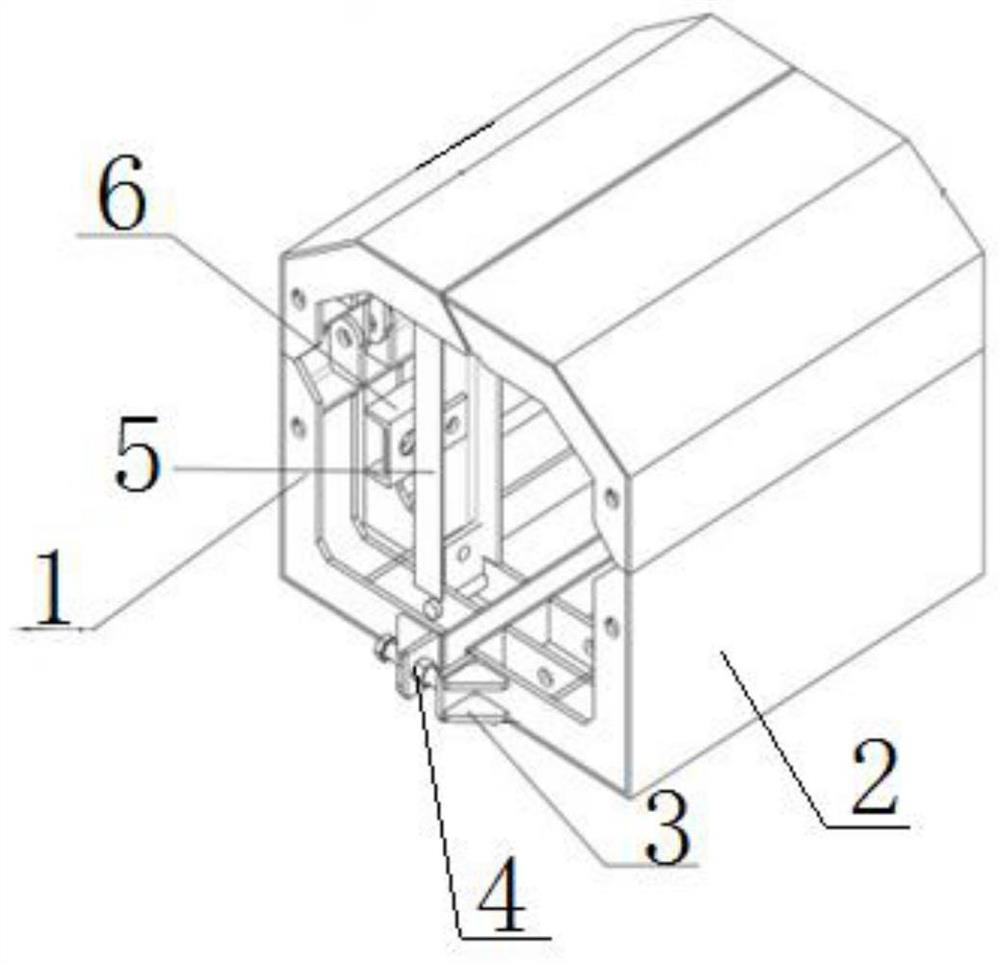

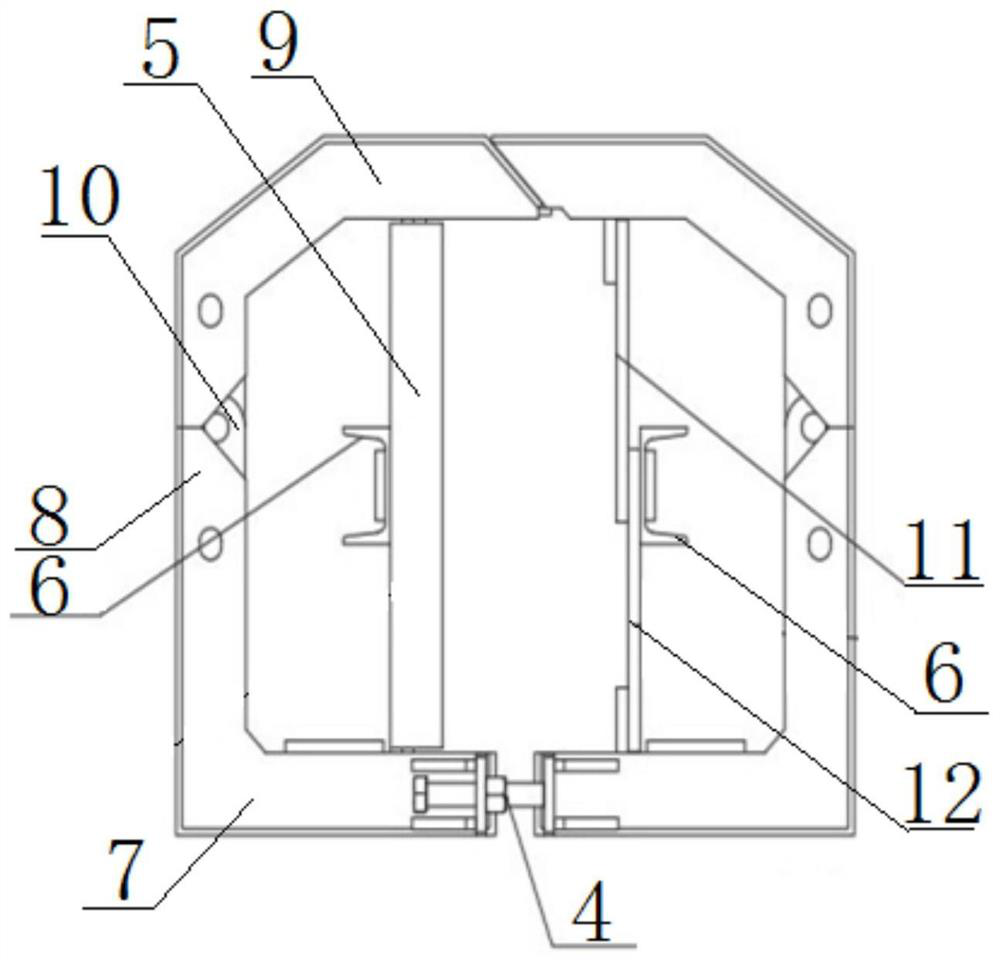

[0045] Such as figure 1 and figure 2 As shown, this embodiment provides an internal mold splicing module, including a first side mold 1, a second side mold 2, and a linkage mechanism. The cross-sections of the first side mold 1 and the second side mold 2 are both C-shaped structures and The lower end surface is horizontal, and the ends of the first side mold 1 and the second side mold 2 are spliced together to form a cavity structure with four sides closed and two sides penetrated. Both the first side form 1 and the second side form 2 include a top plate 9, a bottom plate 7 and a side plate 8. The side plate 8 is arranged in two sections and is connected by a hinge 10. The linkage mechanism includes a plurality of connecting rod groups and pull rods arranged in parallel. 6. The tie rod 6 is arranged along the length direction of the first side mold 1 and the second side mold 2. The connecting rod set includes an upper connecting rod 11 and a lower connecting rod 12. The lo...

Embodiment 2

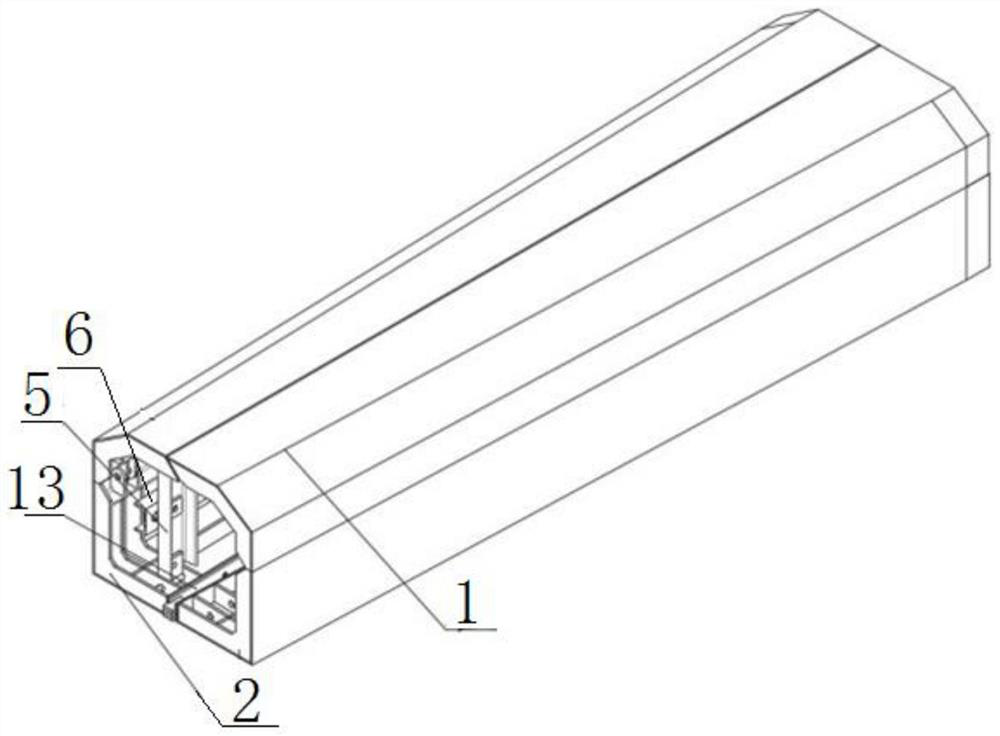

[0047] Such as image 3 and Figure 4 As shown, the present embodiment provides an internal mold splicing module, its structure is roughly the same as that of the internal mold splicing module in Embodiment 1, the difference technical feature is that its width gradually increases along its length direction, and its minimum end surface is the same as that of the implementation The end faces of the inner mold splicing modules in Example 1 are the same, and the height is the same as that of the inner module in Example 1. In this embodiment, the base plate 7 of the first side form 1 and the base plate 7 of the second side form 2 are connected by the first transverse strut 13, the width of the first transverse strut 13 gradually increases along the length direction, and the first transverse strut The length of 13 is less than the length of variable section module 16. The advantage of the first transverse strut 13 being shorter than the variable length is that when the first trans...

Embodiment 3

[0049] Such as Figure 5 and Figure 6 As shown, the present embodiment is a kind of internal mold splicing module, its structure is roughly the same as that of the internal mold splicing module in Embodiment 1, and the difference technical feature is that the bottom plate 7 and the second side of the first side mold 1 in this embodiment The bottom plates 7 of the mold 2 are connected by second transverse struts 14 . Such as Figure 11 As shown, the second transverse strut 14 includes two parallel vertical bars 25 and several horizontal bars 26, the horizontal bars 26 are arranged in parallel along the length direction of the vertical bars 25, and the two ends of the horizontal bars 26 are axially connected with the vertical bars 25 , the second transverse strut 14 is fixedly connected to the bottom pad 18 through pins. The height of the internal mold splicing module in this embodiment is the same as the height of the internal mold splicing modules in Embodiment 1 and Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com