Drum-type thermal-insulation fermentation device used for production of bio-organic fertilizer

A bio-organic fertilizer, heat preservation and fermentation technology, applied in the direction of organic fertilizer, fertilization device, organic fertilizer preparation, etc., can solve the problems of poor temperature control effect, affecting the quality of organic fertilizer, insufficient contact with air, etc., to facilitate horizontal guidance , good constant temperature effect, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

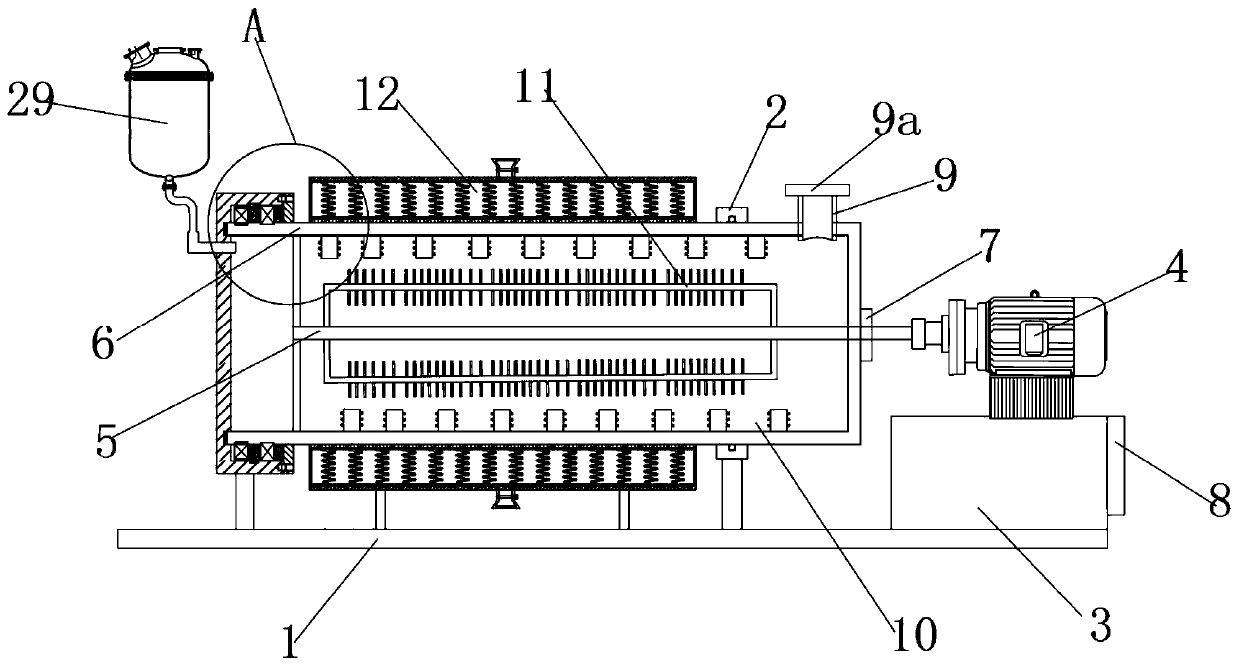

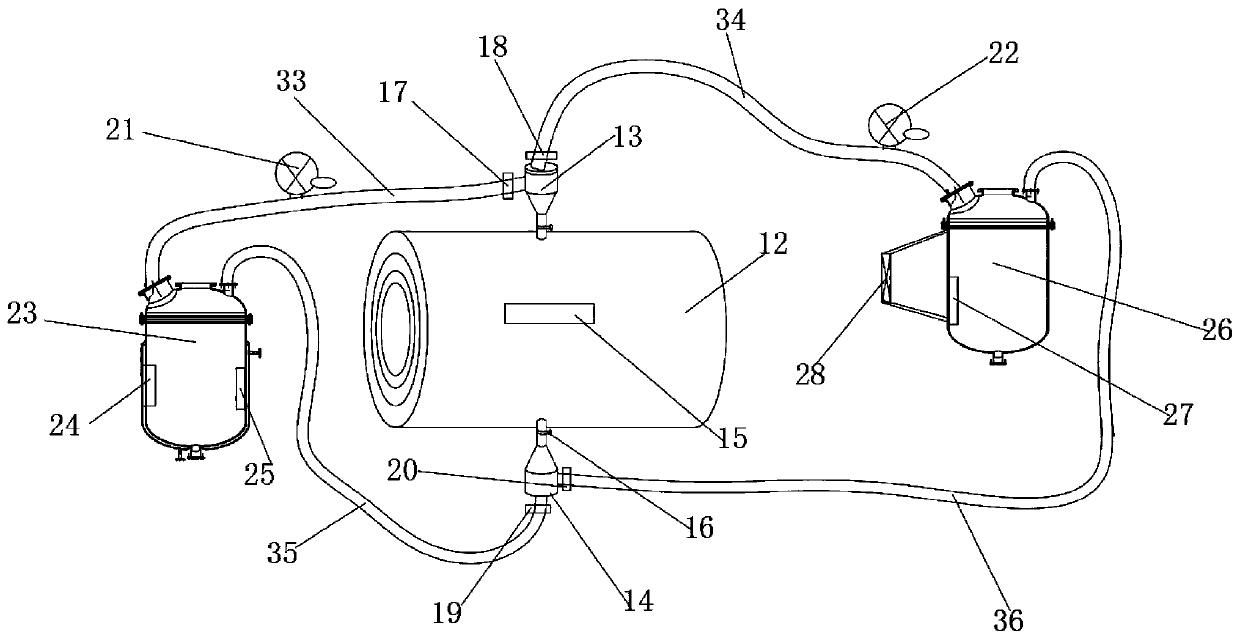

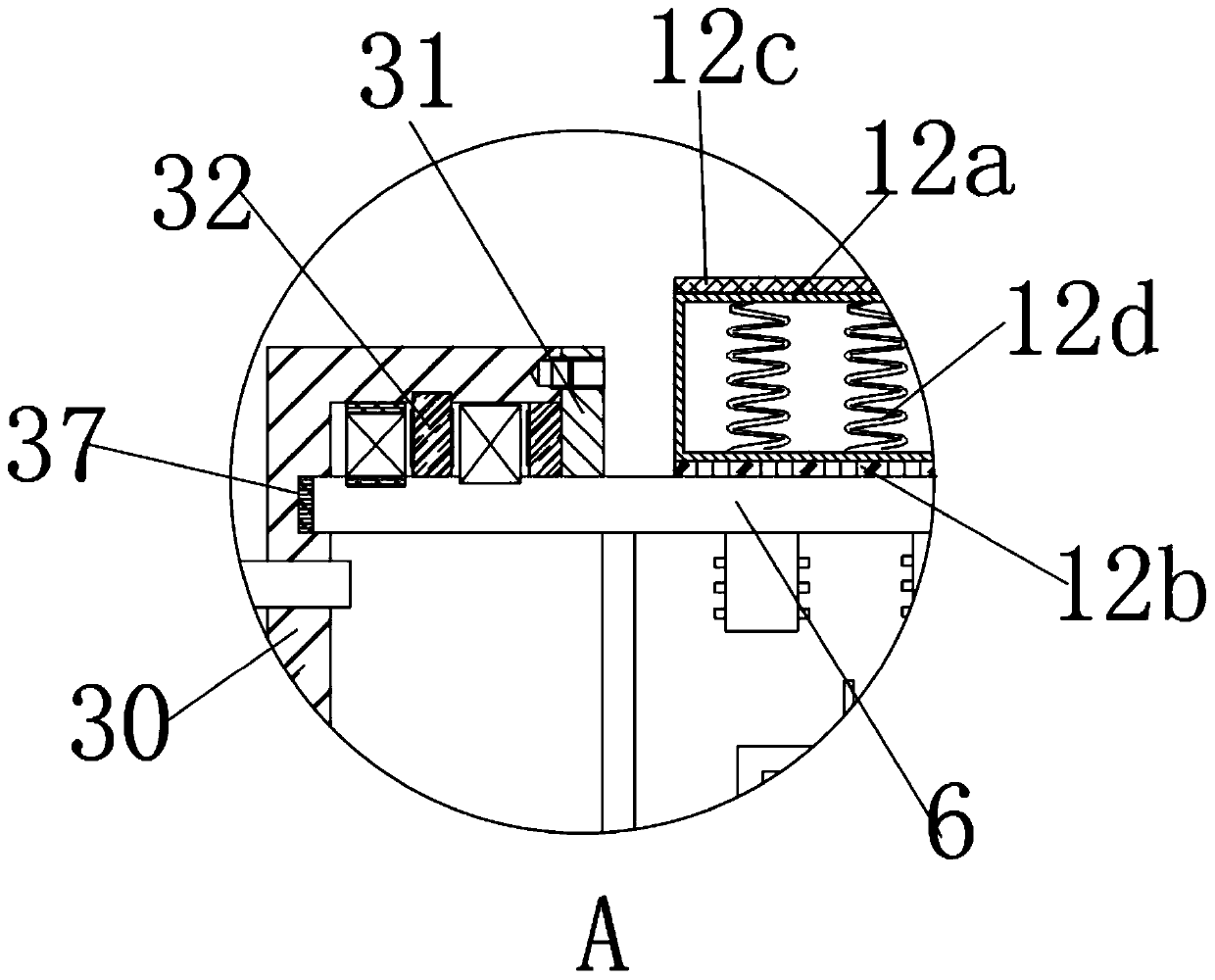

[0029] Example: see Figure 1-4 , the present invention provides a technical solution: a drum-type thermal insulation fermentation device for bio-organic fertilizer production, which includes a drum-type stirring assembly and a temperature control assembly, the drum-type stirring assembly includes a drum 6, and the drum 6 is placed with Bio-organic fertilizer, the drum-type stirring assembly is used to periodically turn and throw the bio-organic fertilizer in the drum 6, and the temperature control assembly is arranged on the outside of the drum 6 for the bio-organic fertilizer at each stage inside the drum 6 Real-time temperature control processing.

[0030]Wherein, the drum type mixing assembly also includes a fixed seat 30 for supporting the rotation of the drum 6 and a support bearing 2, the inner circumference of the support bearing 2 is fixedly sleeved on the drum 6, and the outer circumference of the support bearing 2 The circumference is fixed on the base 1 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com