Stainless steel cold-rolled plate treatment process

A processing technology, cold-rolled sheet technology, applied in the direction of workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of low safety, high production cost, accidental injury of workers, etc., to reduce labor intensity, improve Efficiency and reduction of process changeover time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

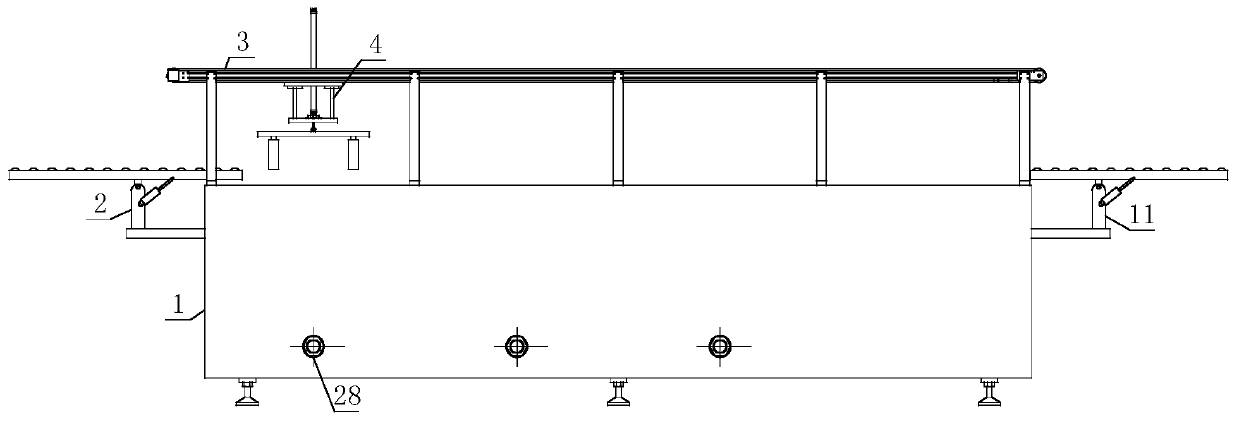

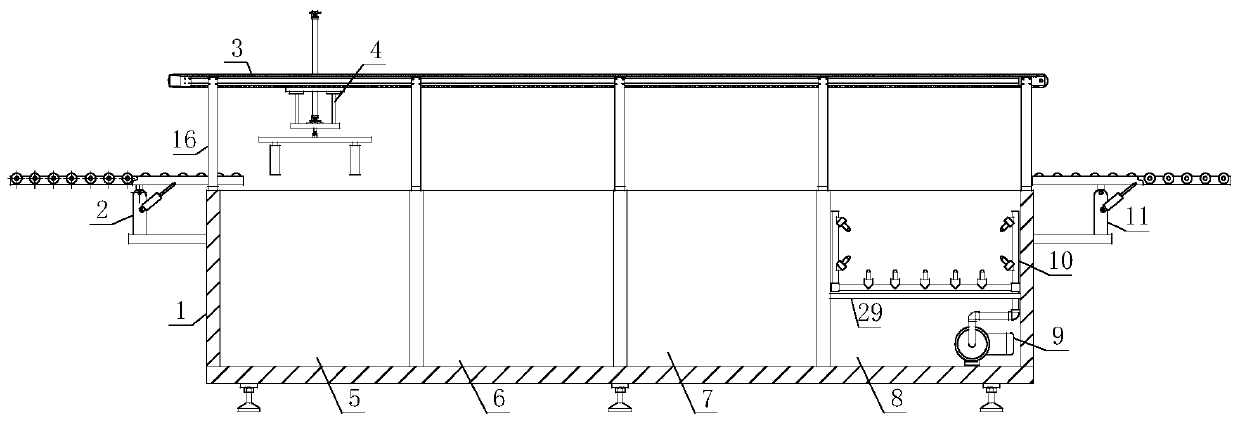

[0031] Such as Figure 1-Figure 7 Shown, a kind of stainless steel cold-rolled plate processing technique of the present invention, this technique comprises the following steps:

[0032] S1: Push the stainless steel cold-rolled plate to the feeding mechanism 2 in the processing device first, and then transfer the stainless steel cold-rolled plate to the clamping mechanism 4 through the feeding mechanism 2, and the stainless steel cold-rolled plate will be made by the action of the feeding mechanism 2 A certain angle of inclination is conducive to making the transition of the stainless steel cold-rolled plate to the clamping mechanism 4;

[0033] S2: On the basis of S1, the clamping structure 4 can be translated in a straight line again, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com