Automatic adjusting device for discharging granularity of jaw crusher

A jaw crusher, automatic adjustment technology, applied in the direction of grain processing, etc., can solve the problems of poor adaptability and accuracy, inability to judge the size of the discharge port, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

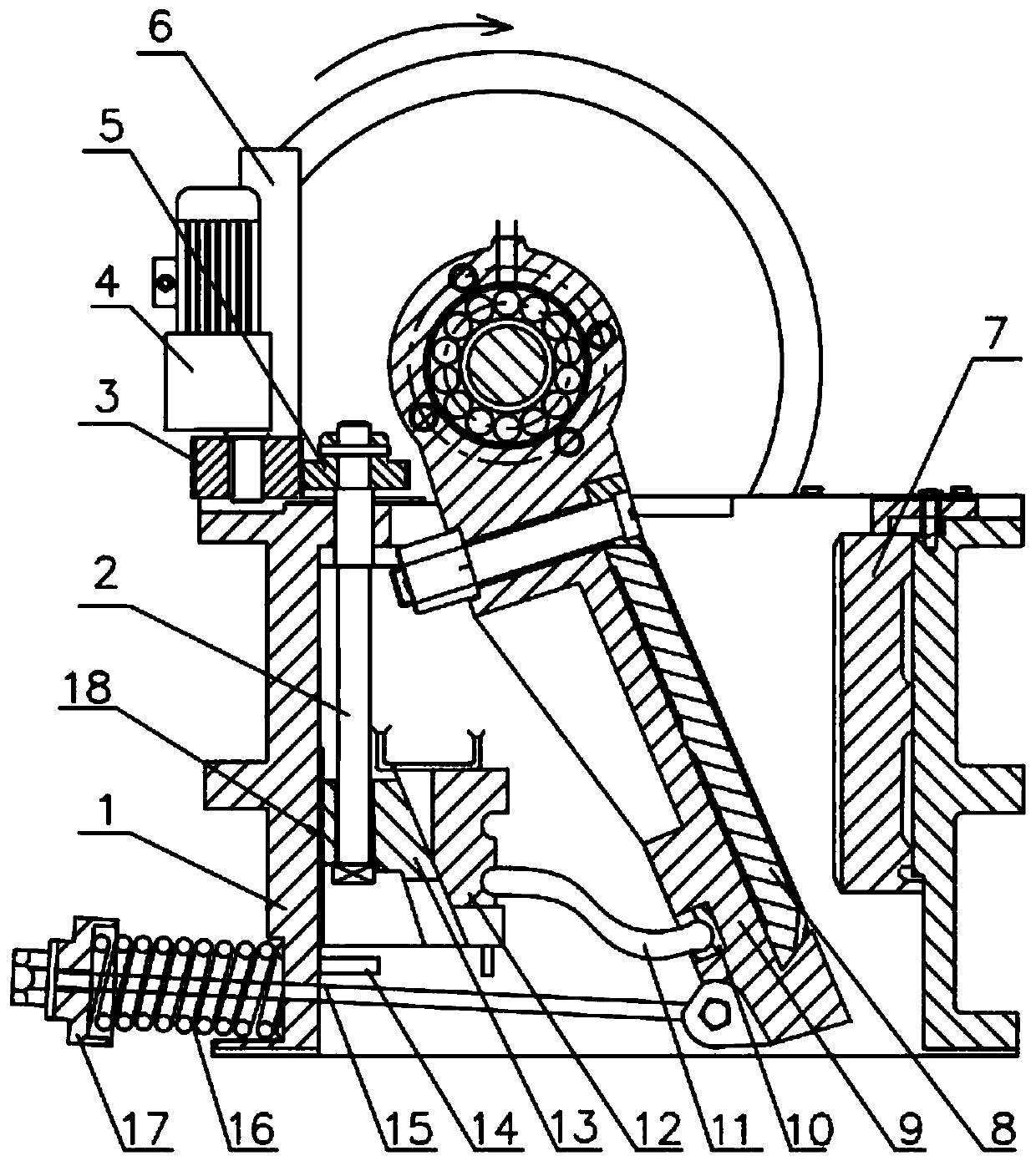

[0015] Such as figure 1 As shown, this embodiment provides an automatic adjustment device for the discharge particle size of a jaw crusher. The jaw crusher includes a machine base 1, a fixed jaw plate 7 arranged on the machine base 1, a movable jaw plate assembly, a pull The tightening assembly and the adjusting device fixed with the movable jaw assembly;

[0016] The movable jaw plate assembly includes a toggle plate 9 and a movable jaw plate 8 arranged on one side of the toggle plate 9; the distance between the bottom end of the movable jaw plate 8 and the bottom end of the fixed jaw plate 7 forms a discharge port;

[0017] The tensioning assembly includes a tensioning screw 15, a spring 16 and a spring seat 17. The front end of the tensioning screw 15 passes through the frame 1 and is hinged at the bottom of the toggle plate 9, and the tail is connected with a spring seat 17. The spring 16 is arranged between the spring seat 17 and the base 1;

[0018] The regulating devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com