Ten-channel organic material automatic stress/strain loading and monitoring device

A technology of organic materials and monitoring devices, applied in the direction of measuring devices, analyzing materials, using stable tension/pressure to test the strength of materials, etc., can solve the research scope of bound stress loading aging tests, increase the cost of test research and test sites, test Insufficient sample size, parallel issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

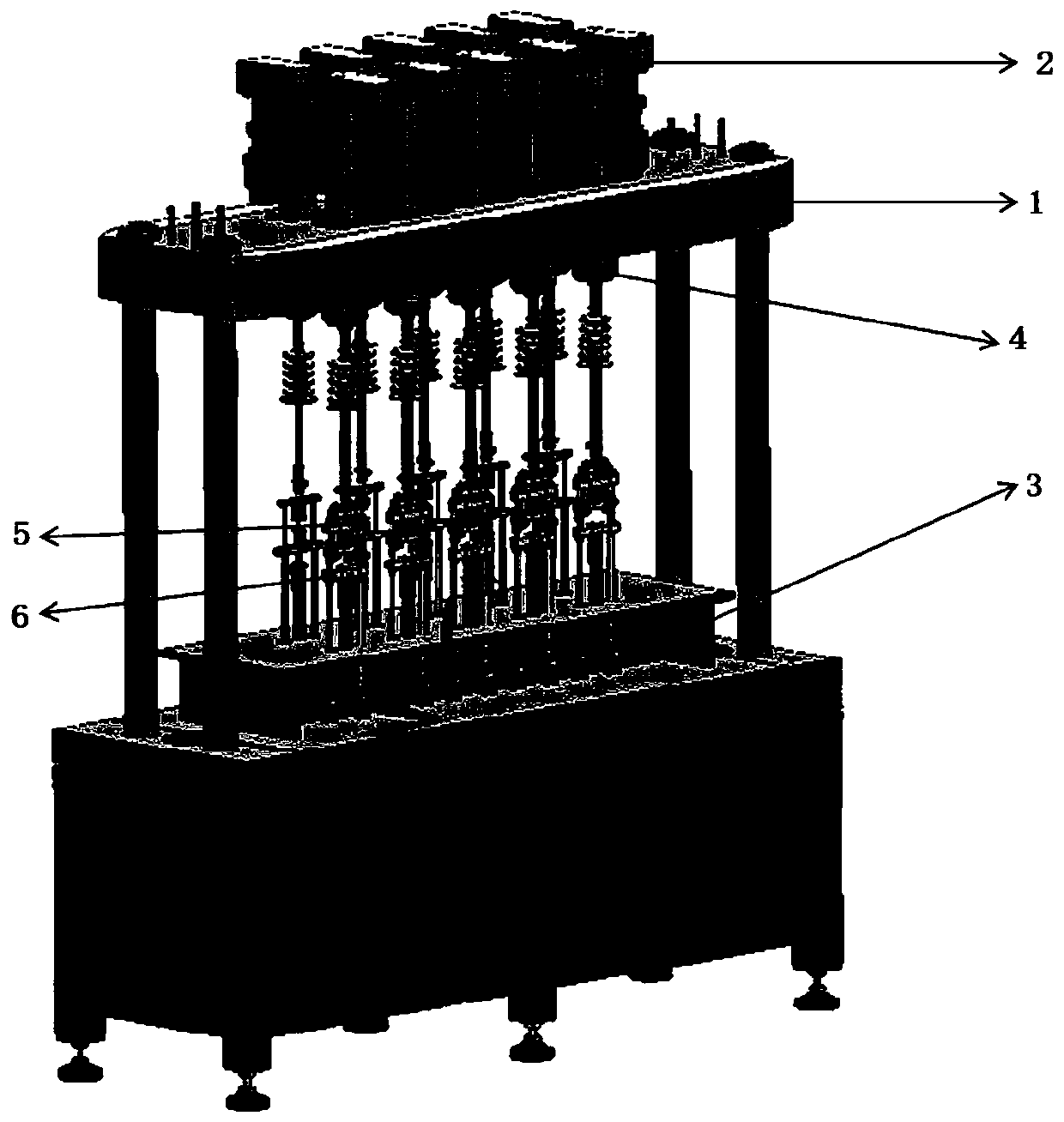

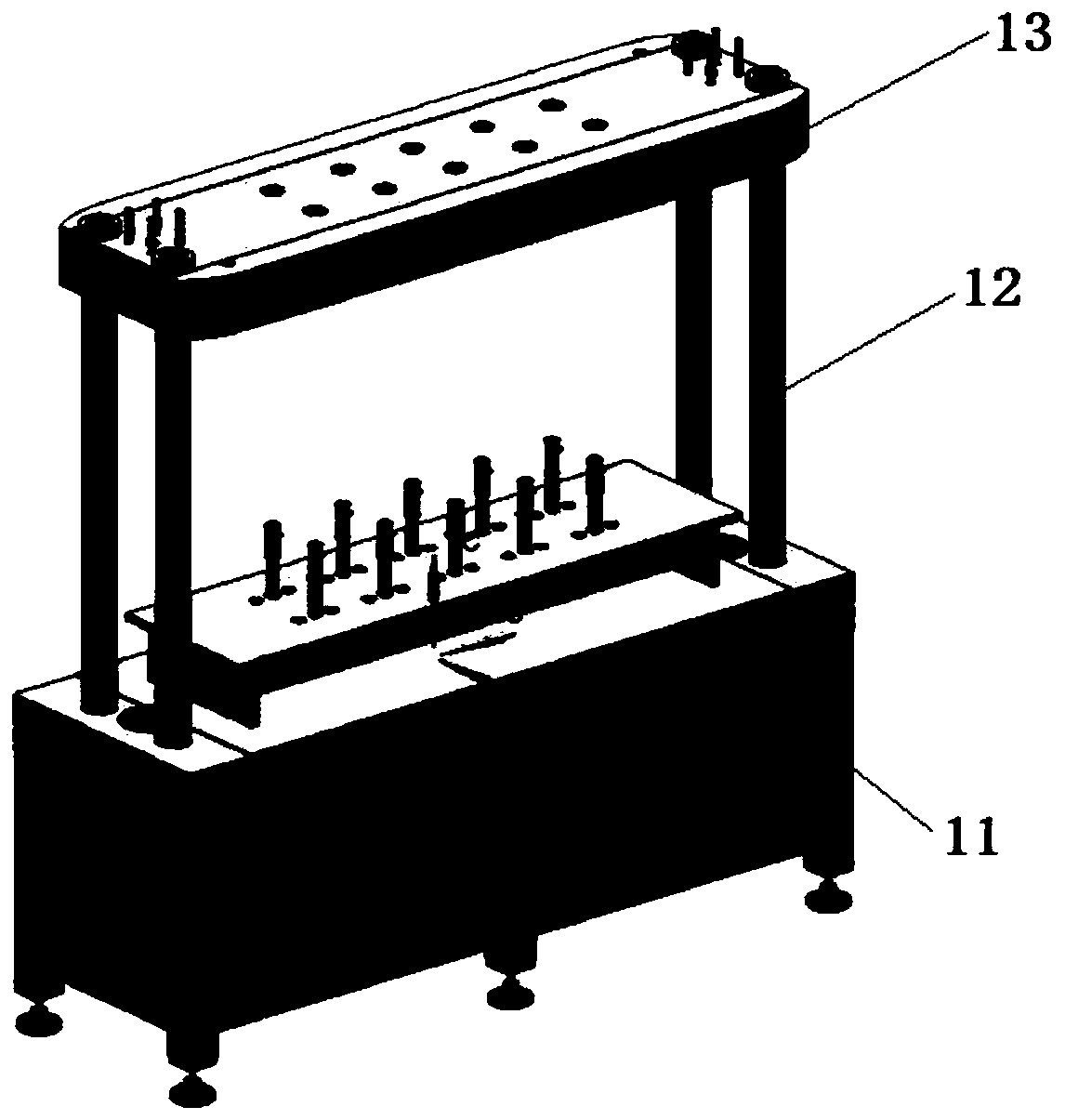

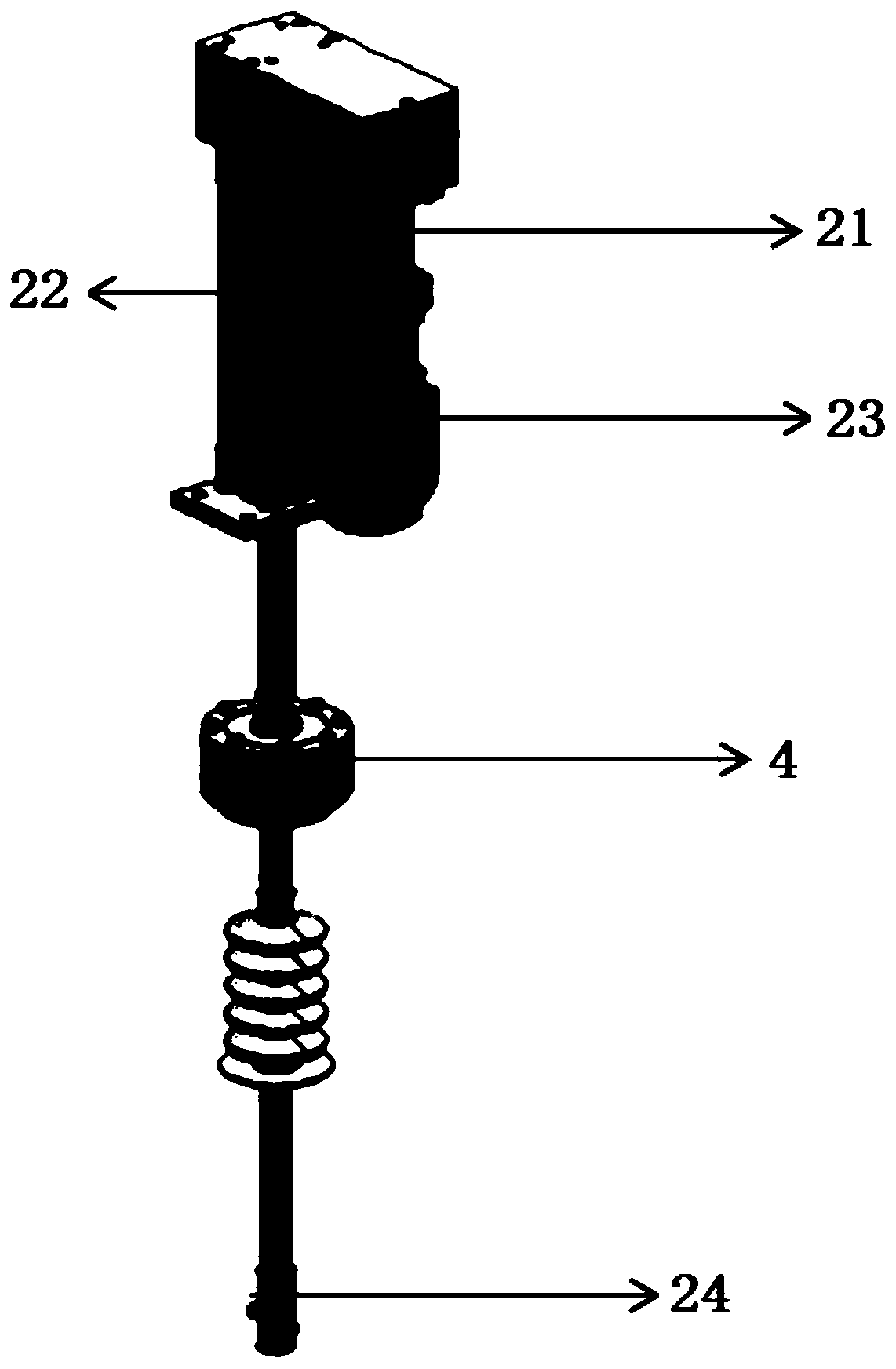

[0017] Such as figure 1 As shown, the present invention provides a ten-channel organic material automatic stress / strain loading and monitoring device, the device includes a main frame 1, the main frame is used to bear stress loading, including a support box 11, a support frame 12 and an upper The cover 13, the supporting box 11 is provided with a loading station, which is arranged in two rows, and each row is provided with five loading axes; the main frame 1 can bear the maximum stress loading under the simultaneous loading condition of 10 axes stress without generating Deformation that affects test data. A clamp is installed on the loading shaft, wherein the clamp includes a compression clamp 5 and a tension clamp 6, which can be replaced. The servo motor system 2 is connected to the clamp, and the servo motor system includes a reducer from top to bottom. 21. An electric cylinder 22, a servo motor 23, a force sensor 4 and a clamp connecting rod 24, and the clamp connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com