Double-wall corrugated pipe

A double-wall corrugated pipe and corrugated ring technology, which is applied in the field of plastic pipe manufacturing, can solve the problems that the bottom of the sludge pipe cannot be cleaned, the outer surface of the double-wall corrugated pipe is oxidized, corroded, and leaked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

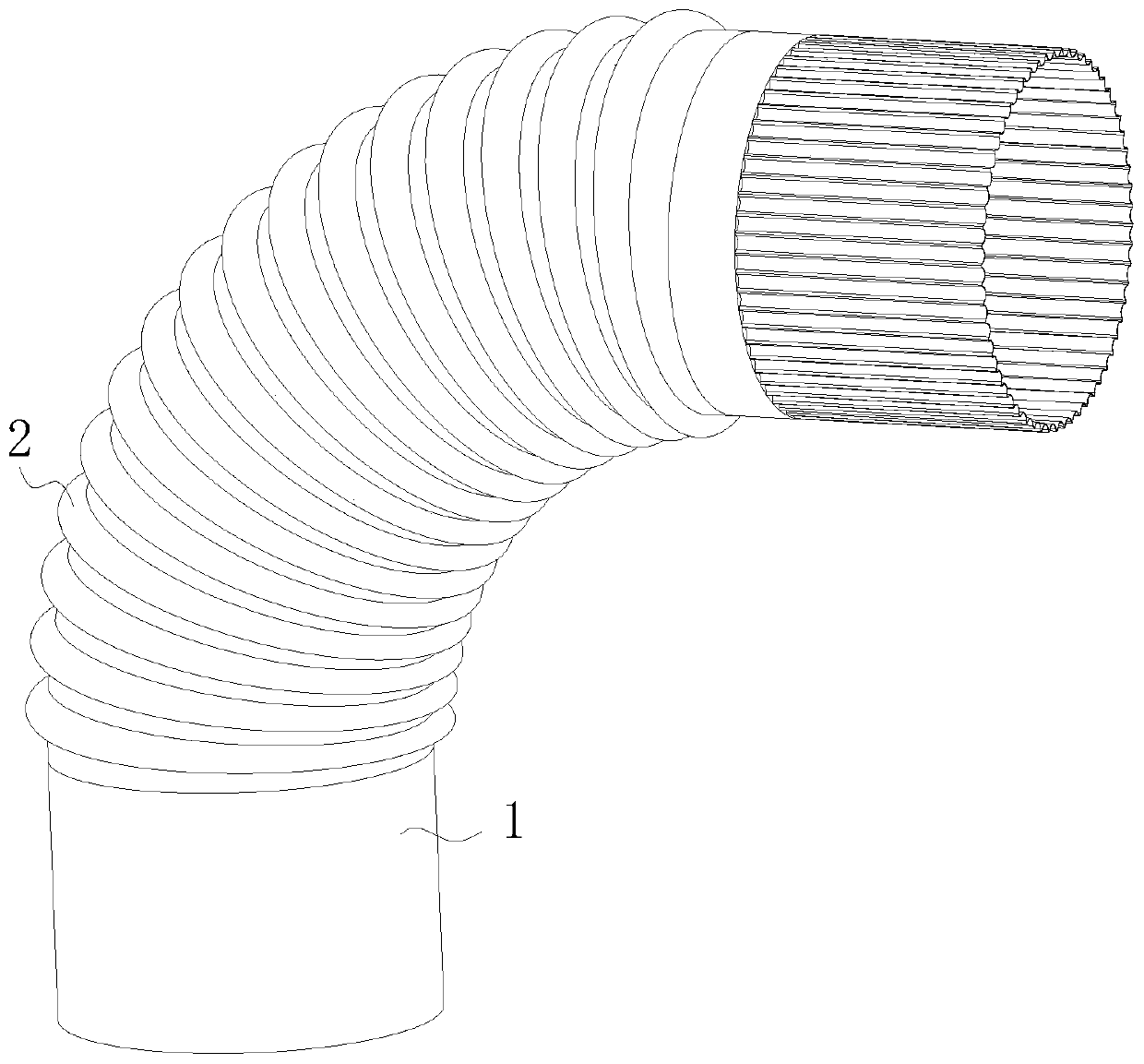

[0018] use Figure 1-Figure 3 A double-wall corrugated pipe according to one embodiment of the present invention will be described below.

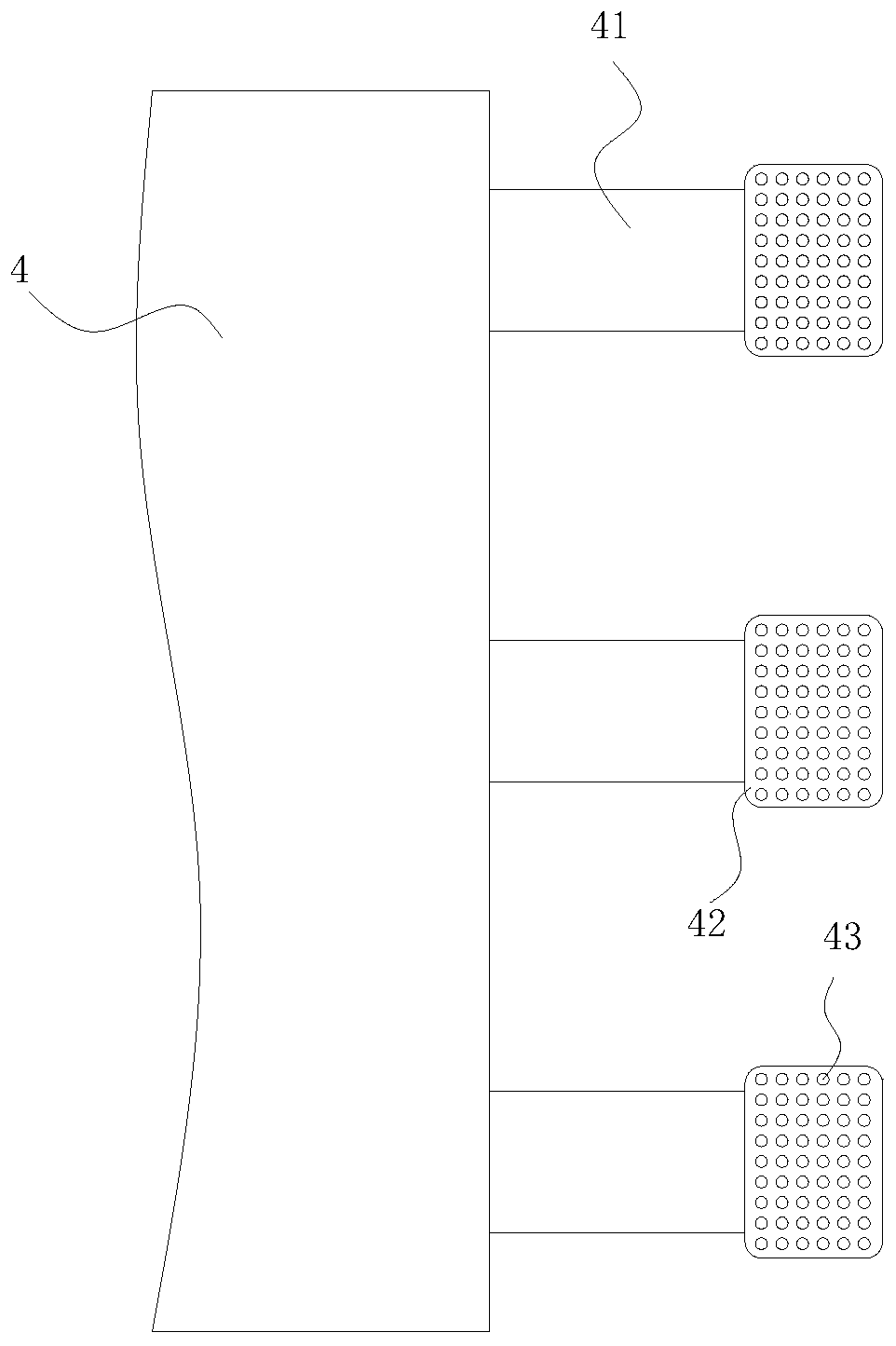

[0019] Such as Figure 1-Figure 3 As shown, a double-wall corrugated pipe according to the present invention includes a pipe body 1, a corrugated ring 2, a rotating ring 3 and a deflector 4; the pipe body 1 is made of high-strength PVC material, and the pipe body 1 The outer surface is evenly spaced and fixedly connected with corrugated rings 2, and the inner wall of the pipe body 1 is rotatably connected with rotating rings 3; the inner surface of the rotating ring 3 is arc-shaped, and the inner wall of the rotating ring 3 is fixedly installed with deflectors 4 The inclination angle of the deflector 4 is set to gradually increase from bottom to top; when the double-wall corrugated pipe starts to transport sewage, because the inner wall of the pipe body 1 rotates at even intervals and is connected with a rotating ring 3, the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com