A three-dimensional structure antimony-doped tin oxide electrode with high efficiency and long life

A technology of antimony-doped tin oxide and three-dimensional structure, which is applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of poor catalytic activity of electrodes and short life of ATO electrodes, and improve the damage of electrode performance and electrochemical active sites. The effect of point improvement and excellent combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0034] A three-dimensional antimony-doped tin oxide electrode with an internal pore size of 50 μm, a thickness of 0.8 mm, and a porosity of 85% was used for SEM characterization, XRD characterization, methylene blue simulated wastewater degradation test, and accelerated life test of the electrode. The amount of modification of the electrode antimony-doped tin oxide catalyst is about 30mg / cm 2 ; The doping ratio of antimony relative to tin in the catalyst is about 5%; the preparation process is the same as Example 1.

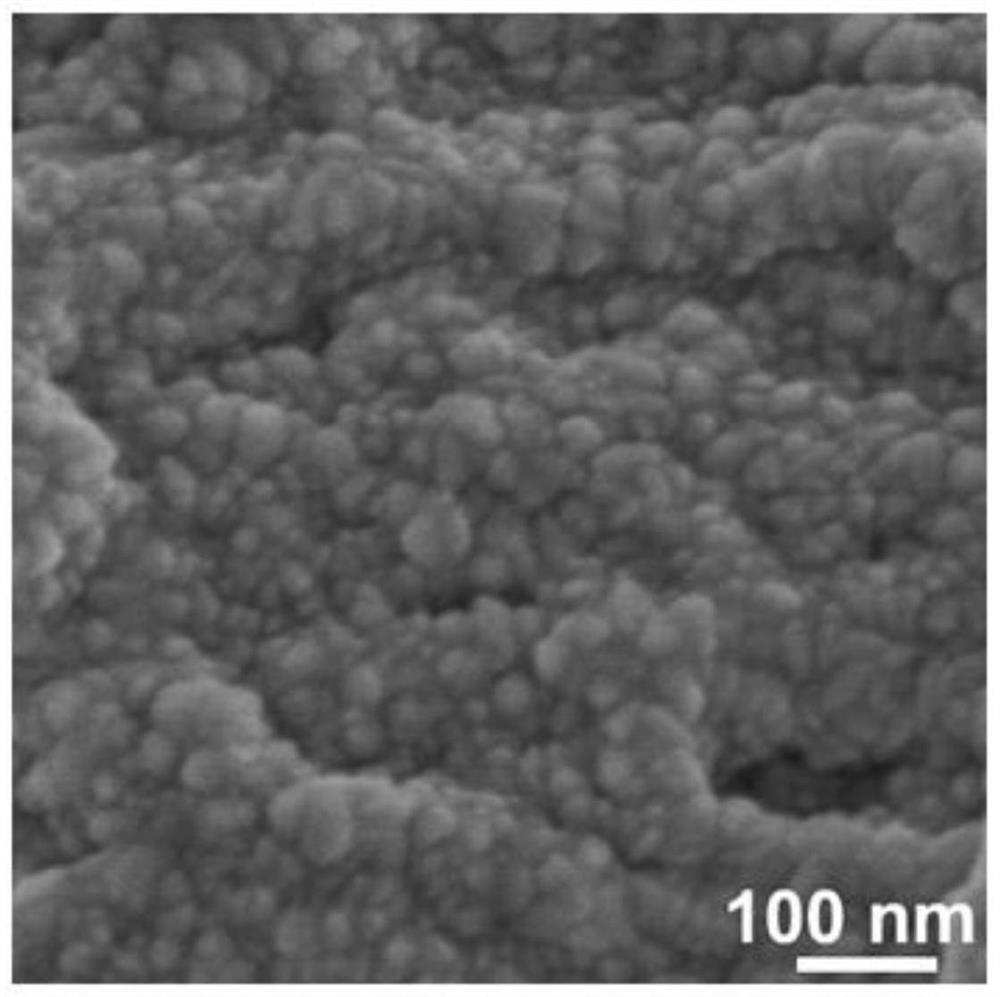

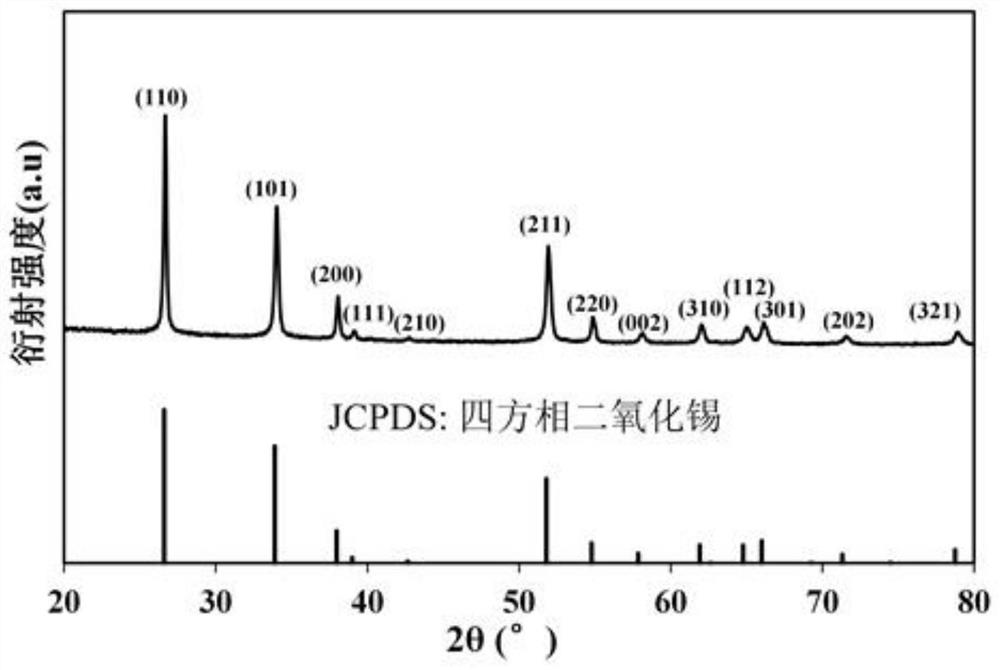

[0035] Characterization of the electrode of the present invention: the surface and section morphology of the electrode is examined by scanning electron microscopy. The catalytic layer on the surface of the electrode is formed by the close connection of nanoparticles with a size of about 50 nm ( figure 1 ), the nano-sized catalyst particles have a high specific surface area, which is beneficial to expose more active sites; the tight connection of the catalyst can...

specific Embodiment 2

[0039] A three-dimensional ATO electrode based on titanium foam with an internal pore size of 150 μm, a thickness of 1.5 mm, and a porosity of 75% was used for SEM characterization, methylene blue simulated wastewater degradation test, and electrode accelerated life test. The amount of modification of the electrode antimony-doped tin oxide catalyst is about 70mg / cm 2 ; The antimony doping ratio is about 20% (relative to Sn); the preparation process is the same as Example 2.

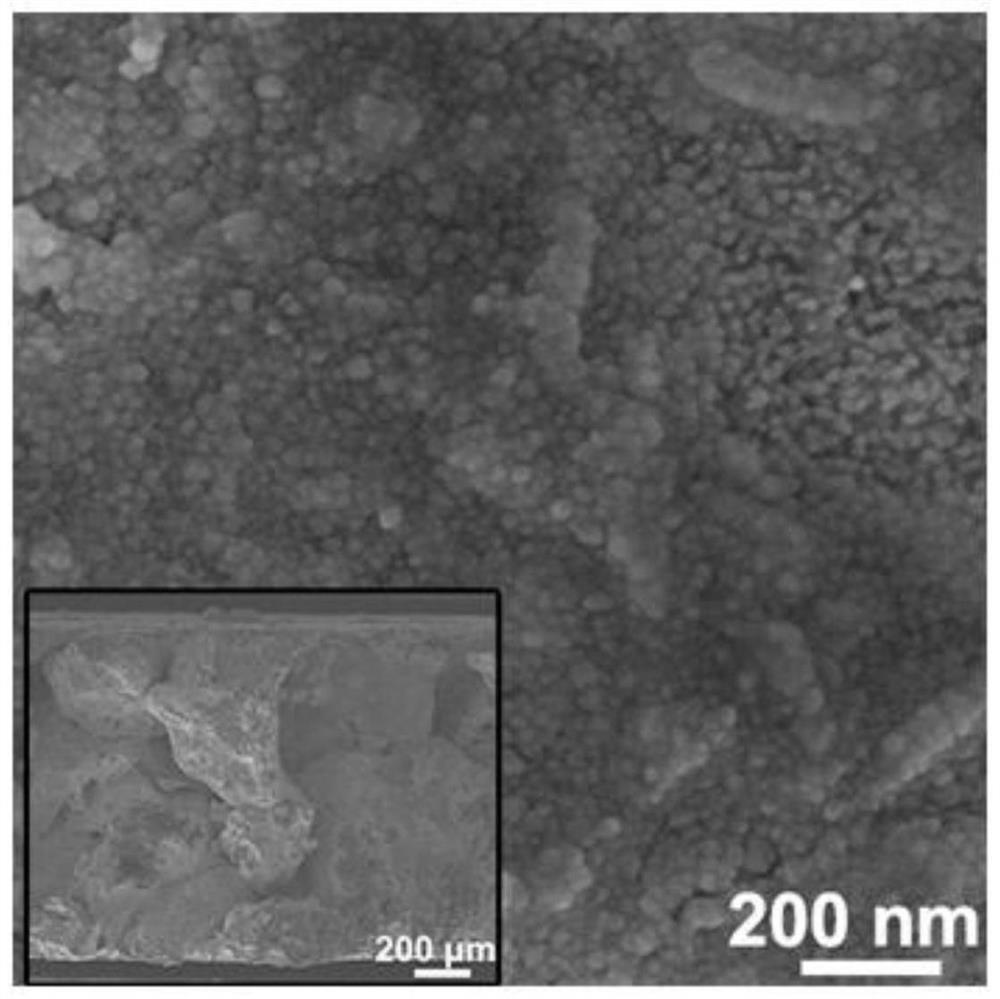

[0040] Use scanning electron microscope to observe the surface and interior of the electrode, such as figure 2 As shown, the interior of titanium foam is full of micro-voids, which can provide a large area of attachment sites for the catalyst. The thermal deposition method can also attach catalyst particles with a size of about 50 nm inside and on the surface of titanium foam to form a three-dimensional antimony-doped tin oxide electrode. , The nano-sized catalyst particles have a high specific surfac...

specific Embodiment 3

[0044] A three-dimensional ATO electrode based on titanium foam with an internal pore diameter of 200 μm, a thickness of 5 mm, and a porosity of 65% was used to conduct methylene blue simulated wastewater degradation tests and electrode accelerated life tests. The modified amount of the electrode is about 190mg / cm 2 ; The antimony doping ratio is about 20% (relative to Sn); the preparation process is the same as Example 3.

[0045] The degradation test procedure of methylene blue simulated wastewater is the same as in specific embodiment 1, and the degradation rate constant of methylene blue simulated wastewater treated by the electrode of the present invention has reached 1.13h -1 .

[0046] The experimental procedure of the accelerated test of the electrode is the same as that of the specific embodiment 1, and the accelerated life test of the electrode of the present invention reaches 300h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com