Organic wastewater catalytic degradation and separation device and method

A technology of organic waste water and separation device, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of lowering catalytic efficiency, reducing the area exposed to light of catalyst, and difficulty in separation and recovery of titanium dioxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

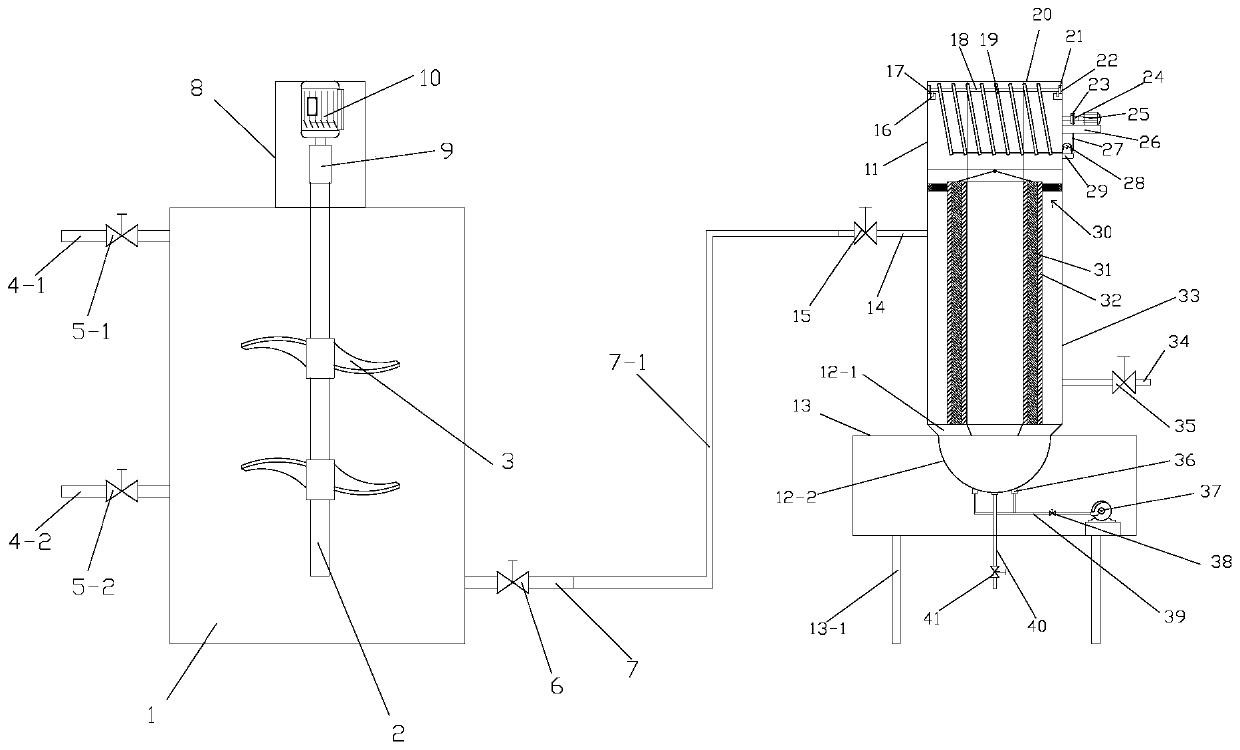

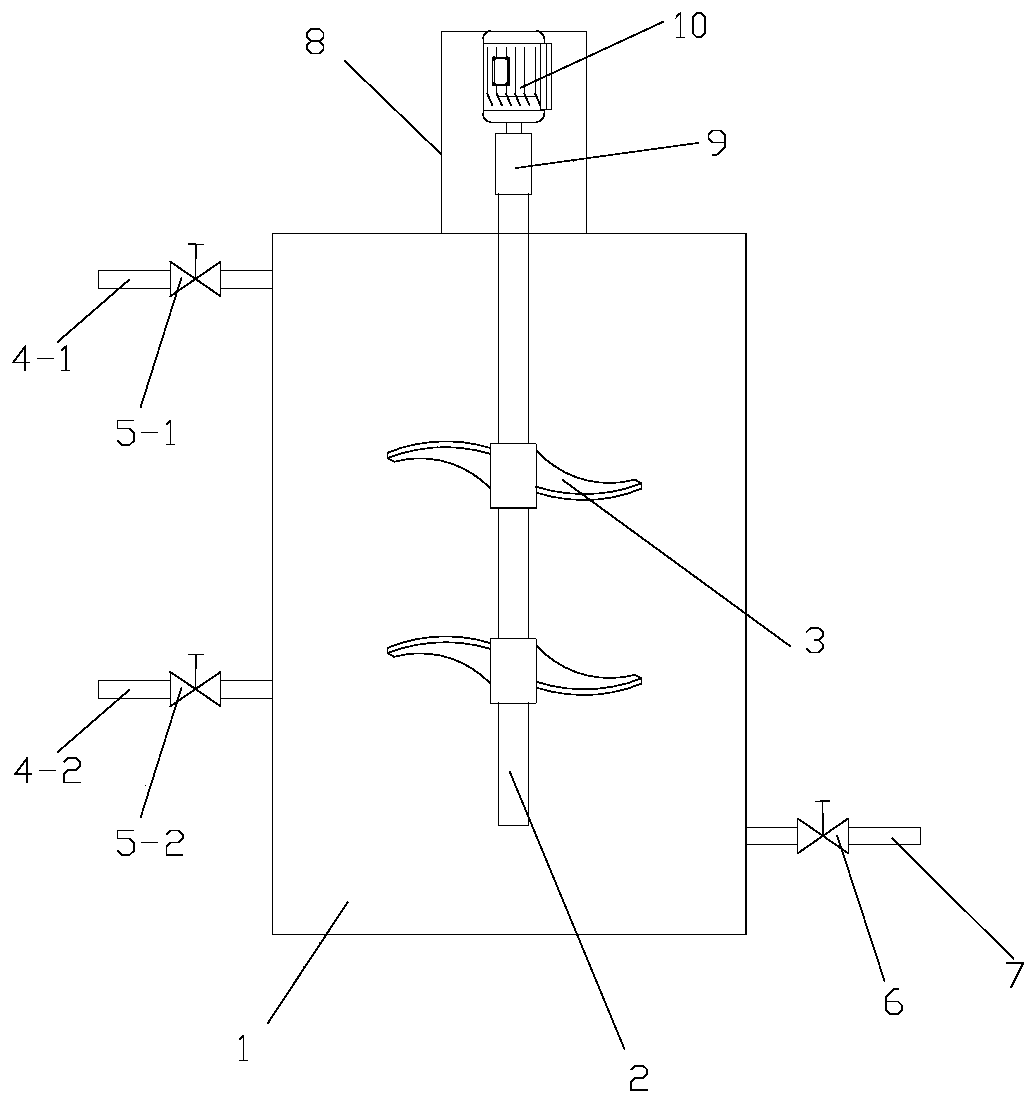

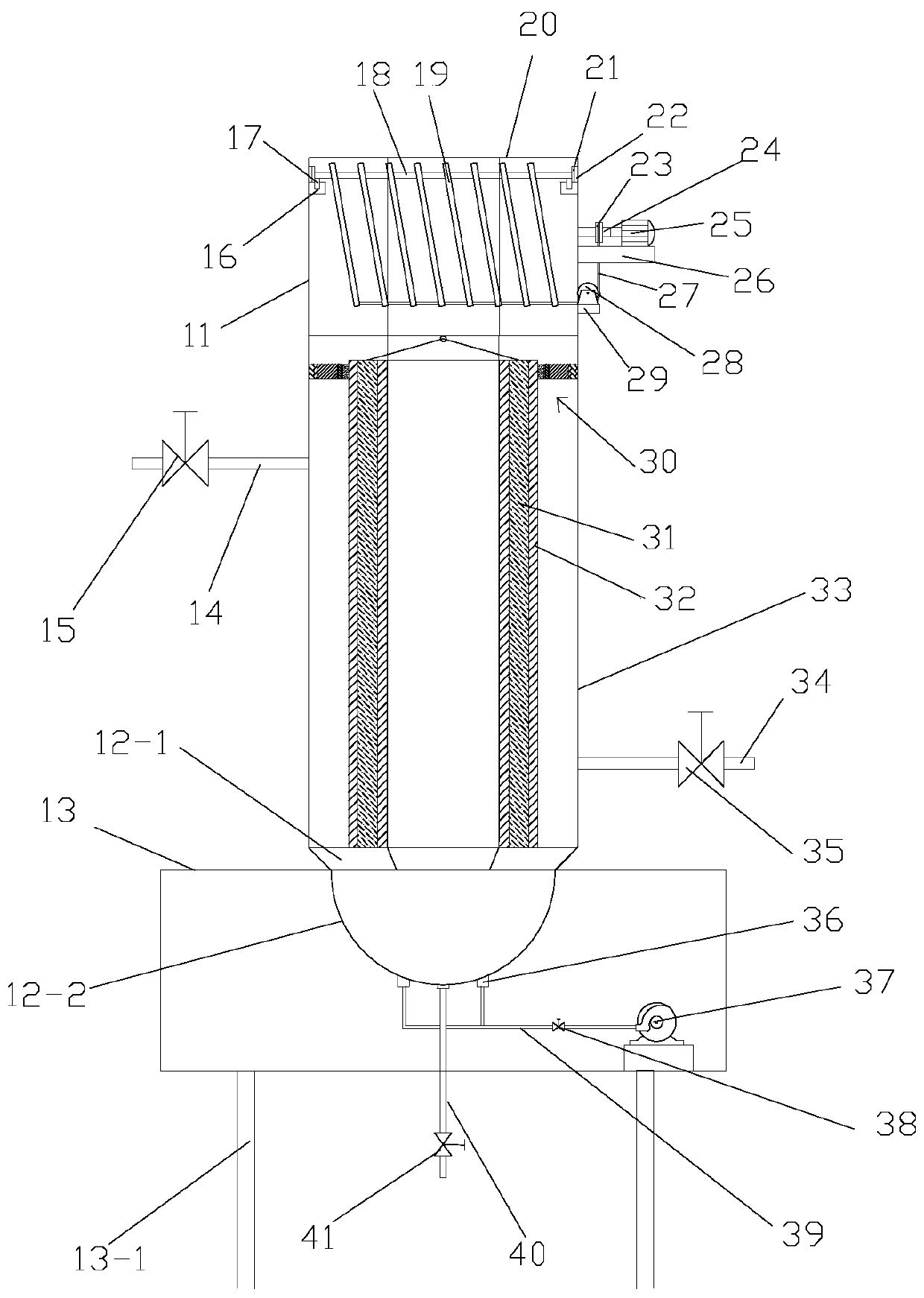

[0085] Such as figure 1 , Figure 6 and Figure 7The shown organic wastewater degradation catalytic separation device includes a dilution mechanism for diluting the organic wastewater, a degradation catalytic separation mechanism for degrading and catalyzing the diluted organic wastewater, and a first control module and a first control module for controlling the dilution mechanism. A second control module that controls the degradation catalytic separation mechanism, the degradation catalytic separation mechanism degrades and catalyzes the diluted organic wastewater to obtain degraded purified water;

[0086] The dilution mechanism includes a dilution tank 1, a stirring mechanism arranged in the dilution tank 1, and a stirring drive mechanism for driving the stirring mechanism to rotate. An upper part of one side of the dilution tank 1 is provided with an inlet and waste water pipe 4-1, and the A water inlet pipe 4-2 is provided in the middle part of one side of the dilution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com