Binding mechanism

A technology of a bundling mechanism and a conveying mechanism, which is applied to the parts of the bundling machine, bundling materials, paper/cardboard containers, etc., can solve the problems of high operation cost, high labor intensity, low production efficiency, etc., and achieves convenient use and structure. clever effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

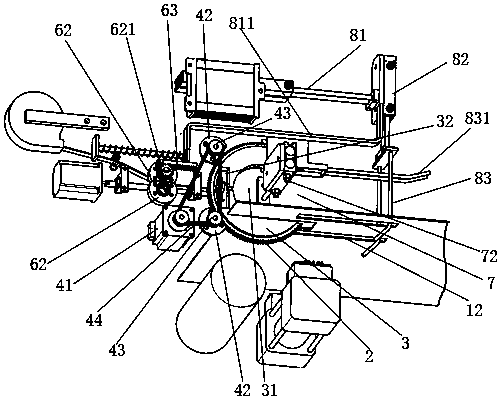

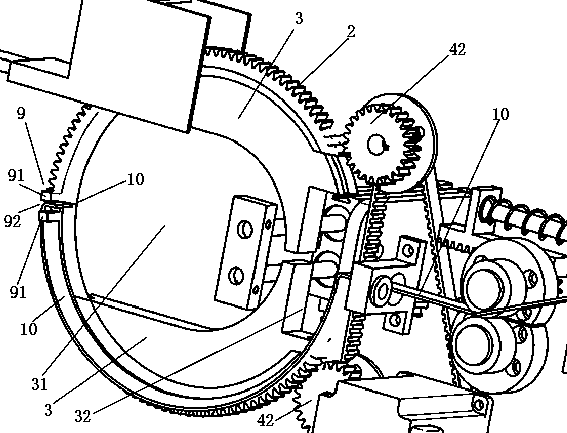

[0022] Such as Figures 1 to 4 As shown, a bundling mechanism includes a pallet 1 , a ring gear 2 , a ring gear seat 3 , a ring gear driving mechanism 4 , a cable tie conveying mechanism 5 , and a cable tie 10 . The ring gear seat 2 is installed above the supporting plate 1; the supporting plate 1 is provided with a ring gear penetration port 11; the inner side of the ring gear seat 3 is provided with a bundling section 31 with a gap ; The ring gear drive mechanism 4 drives the ring gear 2 to perform a periodic movement of one revolution after passing through the ring gear through the ring gear hole 11 outside the ring gear seat 3; one side of the ring gear 2 is provided with a cable tie clamping Mechanism 9; the cable tie conveying mechanism 5 periodically transports one end of the cable tie 10 to the cable tie clamping mechanism 9 on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com