Fast curing method and device used after electrostatic coating performed on surfaces of strip steel with powder

An electrostatic coating and rapid curing technology, which is applied to the surface coating liquid device, electrostatic spraying device, spraying device, etc., can solve the problems that the coating cannot be evenly coated and is prone to peeling, so as to prevent heat loss , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

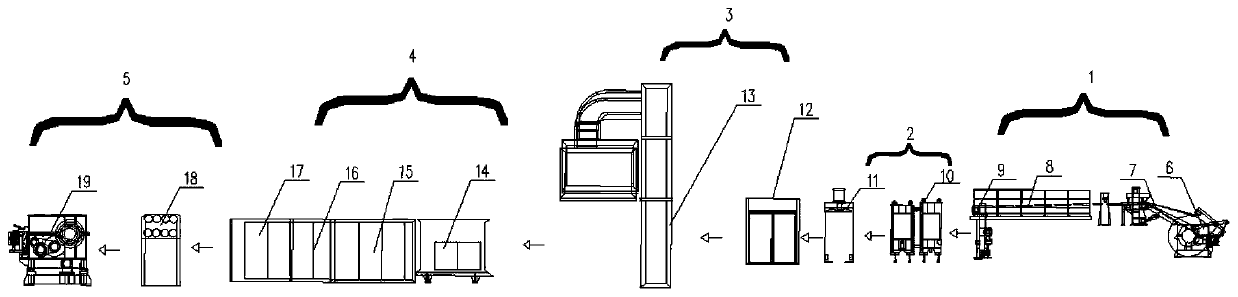

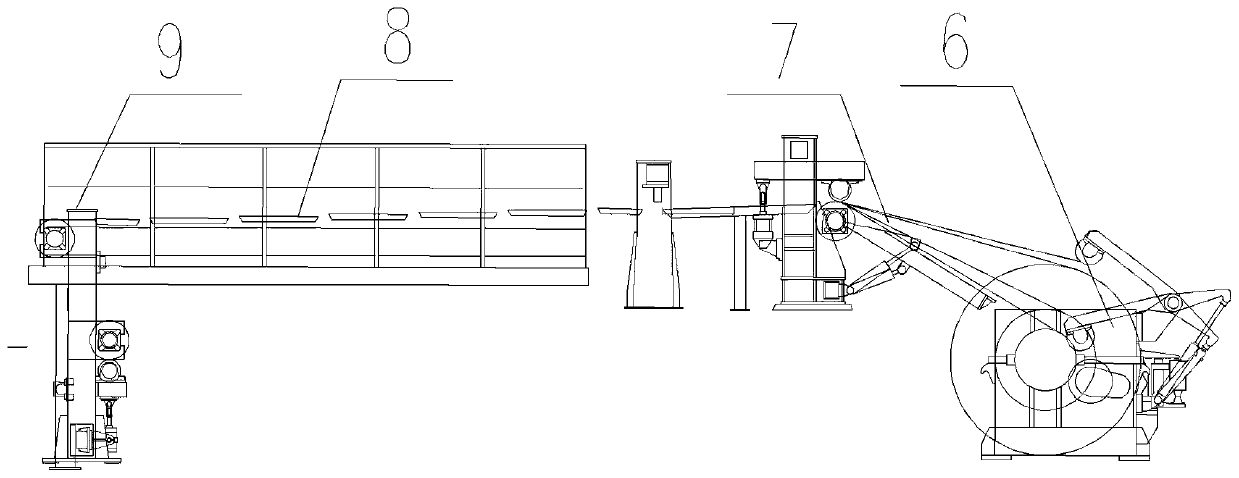

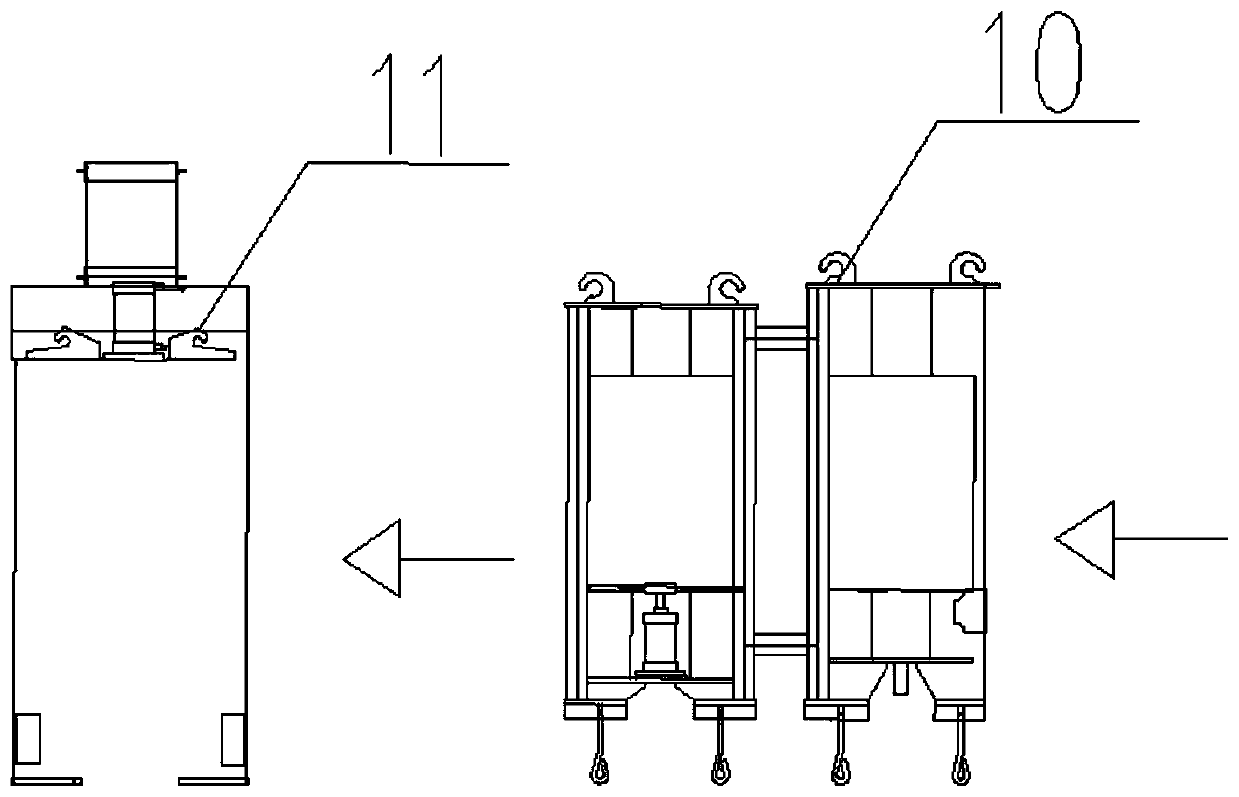

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0029]A method for rapid solidification after electrostatically coating powder on the surface of a steel strip, comprising the following steps: (1) the steel strip is uncoiled by an uncoiling device, (2) a cleaning device is cleaned, (3) a chemical coating device is used for chemical coating, (4) ) Curing furnace curing, (5) Rewinding device winding, after the strip steel is chemically coated, it passes through the melting device of the curing furnace, so that the powder coating on the upper and lower surfaces of the strip steel reaches a molten state, and then passes through the leveling device of the curing furnace The strip steel coating is solidified evenly. After the solidification is completed, the strip steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com