Fresh leaf grading device for grading fresh tea leaves and tea leaf picker

The technology of a grading device and a tea picking machine is applied in the directions of picking machines, applications, harvesting machines, etc., and can solve the problems of squeezing and damage of high-quality tender leaves and tender buds, low variety of tender leaves and tender buds, and consuming a lot of manpower and material resources. Achieve the effect of improving picking quality, facilitating grading work, and reducing the amount of collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

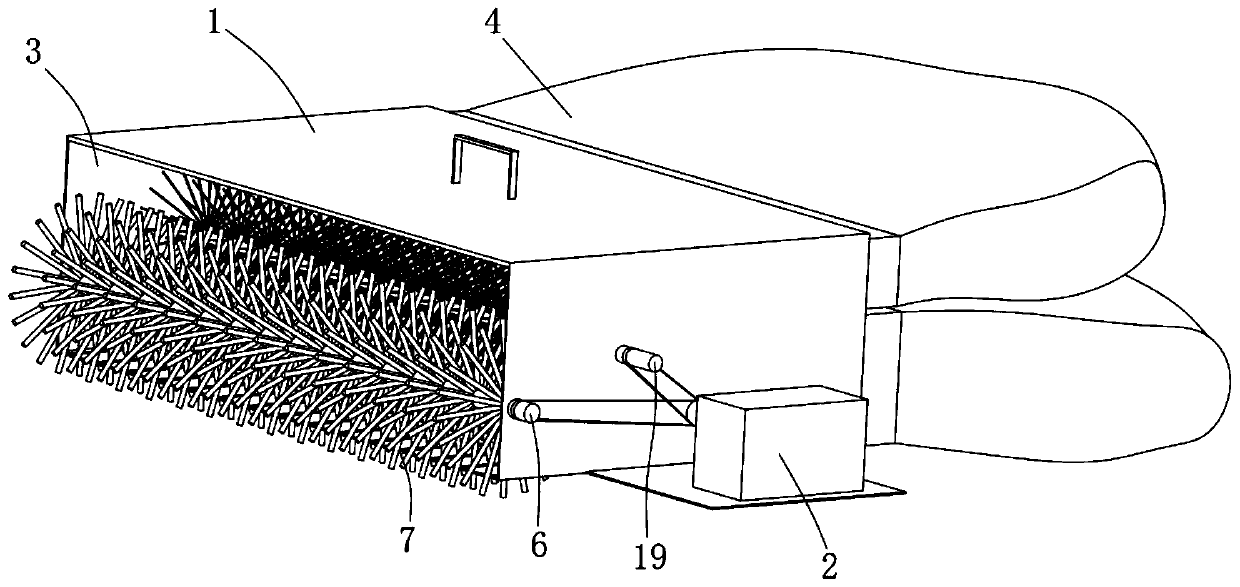

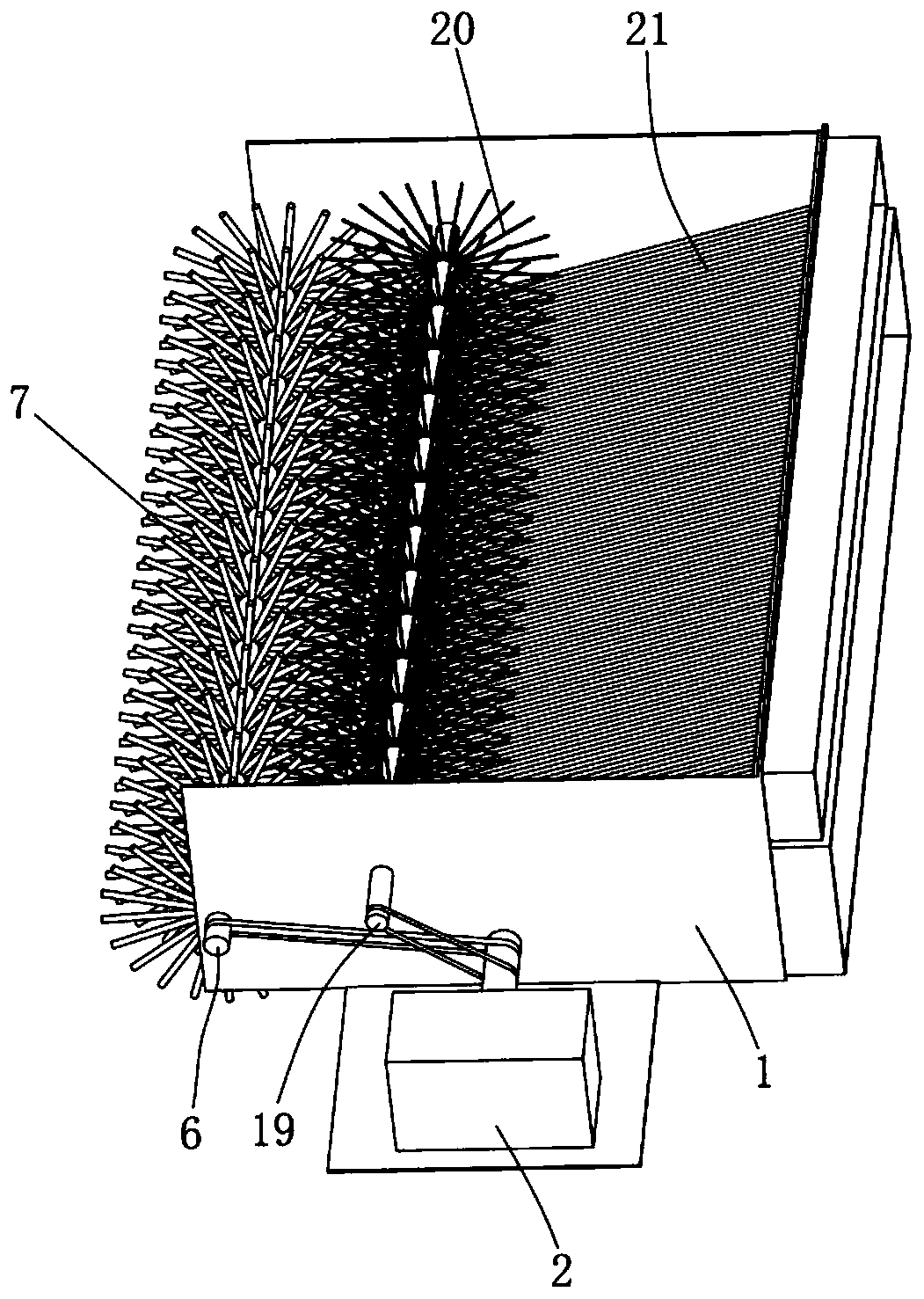

[0070] Example 1, such as Figure 1-4 and 7 as shown:

[0071] A fresh leaf grading device used for grading fresh leaves of tea leaves, comprising a grading sieve 21, the grading sieve 21 is provided with a number of sieve holes 22, and the size of the sieve holes 22 is adapted to the fresh tea leaves with one bud and one leaf, The grading sieve 21 is arranged obliquely, and the lower end of the grading sieve 21 cooperates with the picking assembly of the tea picking machine, so that the tea leaves collected by the picking assembly are located above the grading sieve 21, and the discharge port of the tea picking machine There are two, including the first discharge port 17 on the top and the second discharge port 18 below the first discharge port 17, the first discharge port 17 and the second discharge port 18 are each A collection assembly 4 is provided, and the higher end of the grading screen 21 is arranged at the lower edge of the first discharge port 17 .

[0072] The fr...

Embodiment 2

[0082] Example 2, such as Figure 1-9 as shown,

[0083] A tea picking machine includes the above-mentioned fresh leaf grading assembly.

[0084] The tea picking machine of this embodiment is equipped with the above-mentioned fresh leaf grading assembly, and the young leaves and shoots at the screening place are transported separately, reducing the risk of damage during the turnover process, thus improving the picking quality of high-quality tea.

[0085] As a preferred embodiment, the tea picking machine also includes a collection box 1, a picking assembly arranged in the collection box 1, and a driving part 2 for driving the picking assembly, and the collection box 1 is horizontally One end of the direction is the entry end 3 for the fresh leaves of tea to enter, the entry end 3 is open, and a collection assembly 4 is also arranged on the collection box 1, and the collection assembly 4 is used to collect the collection box The tea leaves were picked within 1,

[0086] The...

Embodiment 3

[0114] Example 3, such as Figure 1-9 as shown,

[0115] A method for picking tea leaves, comprising the steps in turn:

[0116] Step 1, initial mining, using the above-mentioned tea picking machine to collect the leaf buds on the tea tree treetops;

[0117] Step 2, Jingcai, manually collect the leaf buds on the tea tree treetops collected in step 1;

[0118] Step 3, machine harvesting, using a shearing tea picking machine to collect the tea tree tops collected in step 2.

[0119] The tea picking method of this embodiment is especially suitable for the graded picking of tea leaves. In step 1, the tea picking machine mentioned above in this embodiment is used to collect the leaf buds. Adjustment of high-quality tea leaves such as one bud with one leaf, one bud with two leaves, and one bud with three leaves. Picking again by manual picking, because a large part of the collection is completed in step 1, so the collection of step 2 is more convenient and quick, after the colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com