An Algorithm for Improving the Point Cloud Density Calculation of Sheet Surface by 3D Profile Sensor

A sensor and cloud density technology, applied in computing, computing models, instruments, etc., can solve the problems of increasing manufacturing cost, price increase, unacceptable manufacturing cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

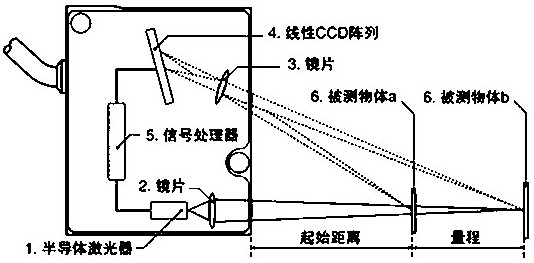

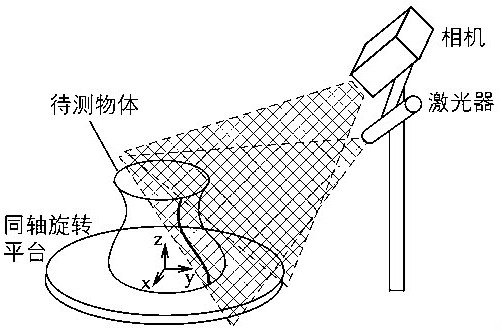

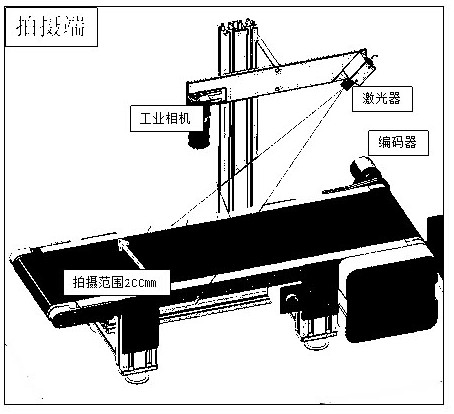

[0057] Such as figure 1 As shown in Fig. 1, the algorithm for improving the 3D profile sensor to calculate the point cloud density of the plate surface is shown. First, build a set of ultra-high standard equipment for obtaining real data with high-grade lasers and industrial cameras. Use this set of equipment to scan a large number of specific types of panels (such as wood panels) to be inspected to obtain ultra-high-density point cloud data for training and testing of this type of panels.

[0058] For any specific type of plate, the depth value (z value) of a certain coordinate (x, y) in the point cloud density map has a certain cross-correlation with the depth values of a series of coordinates around the point. Convert the point cloud data into a 2D depth map; then normalize the depth map and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com