Fault detection and classification method of valve-controlled electro-hydraulic servo system based on observer group

An electro-hydraulic servo system and fault detection technology, applied in general control systems, control/regulation systems, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings of the description.

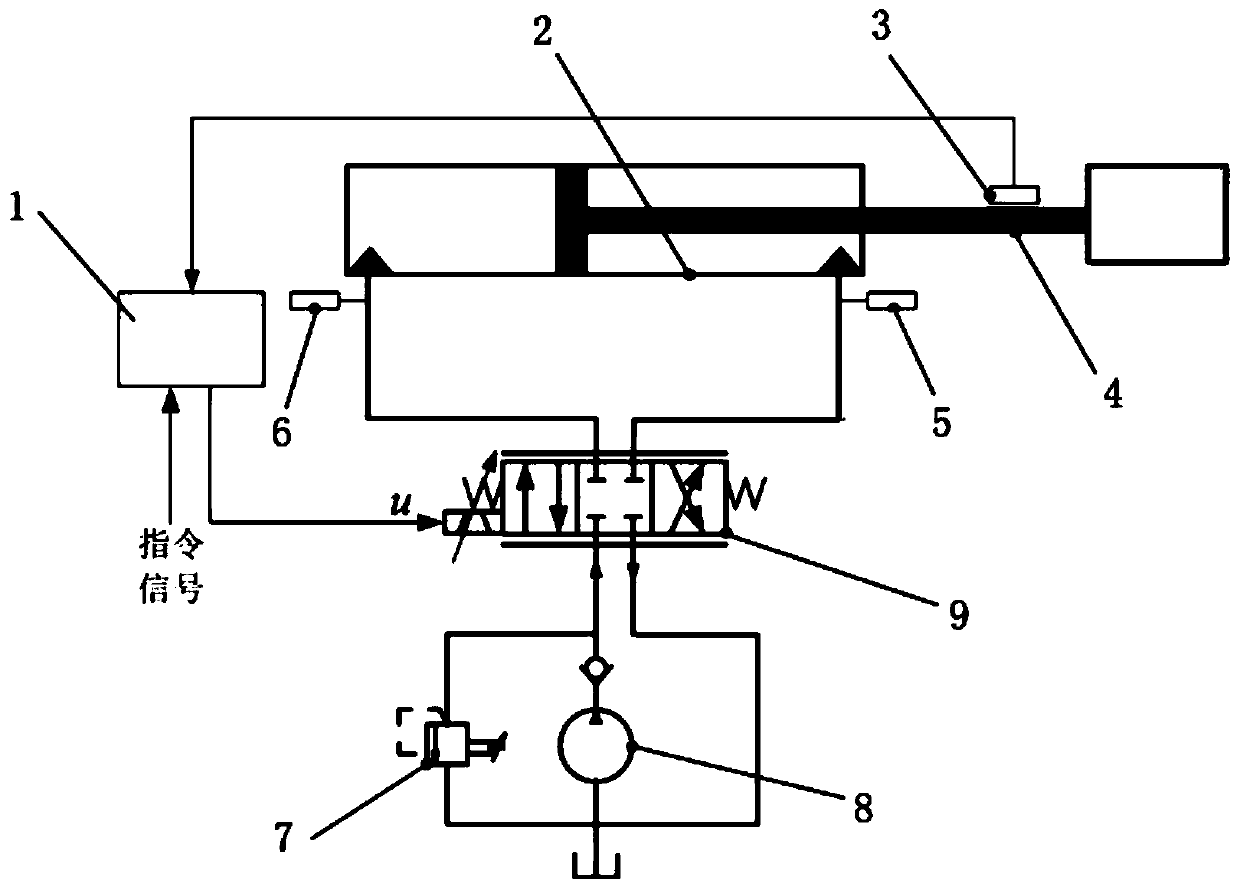

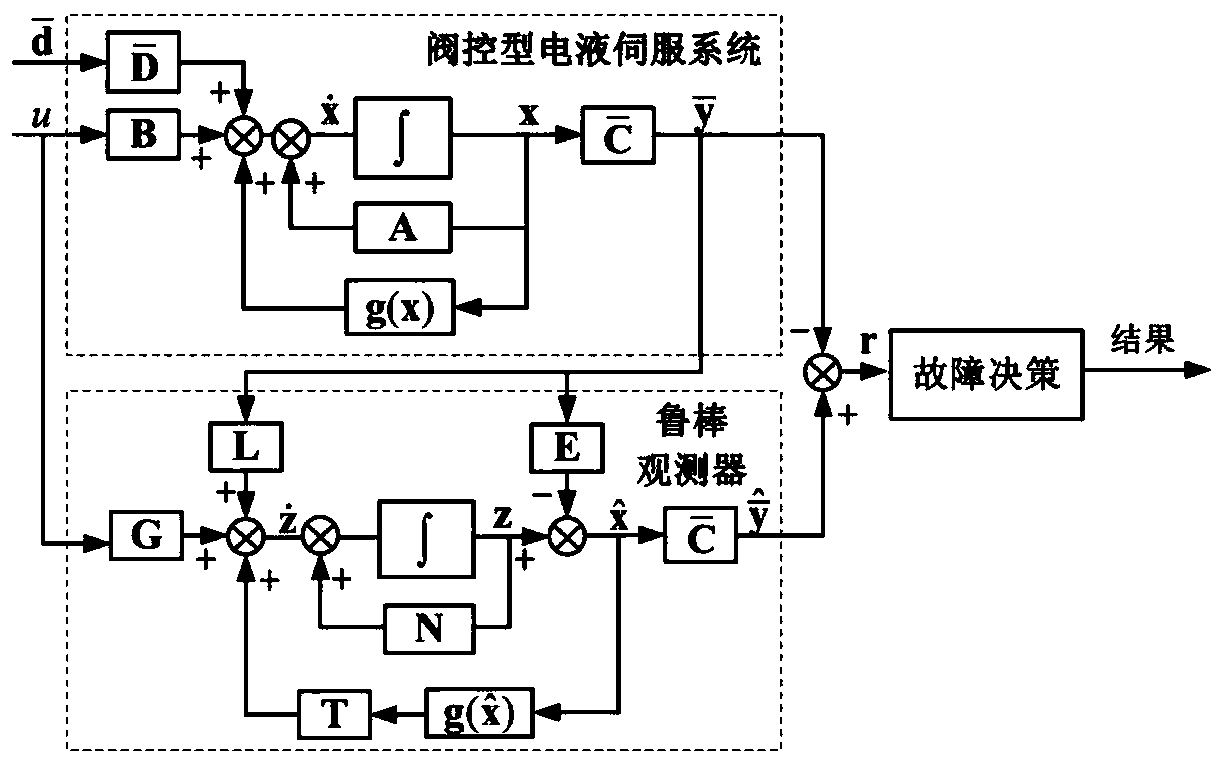

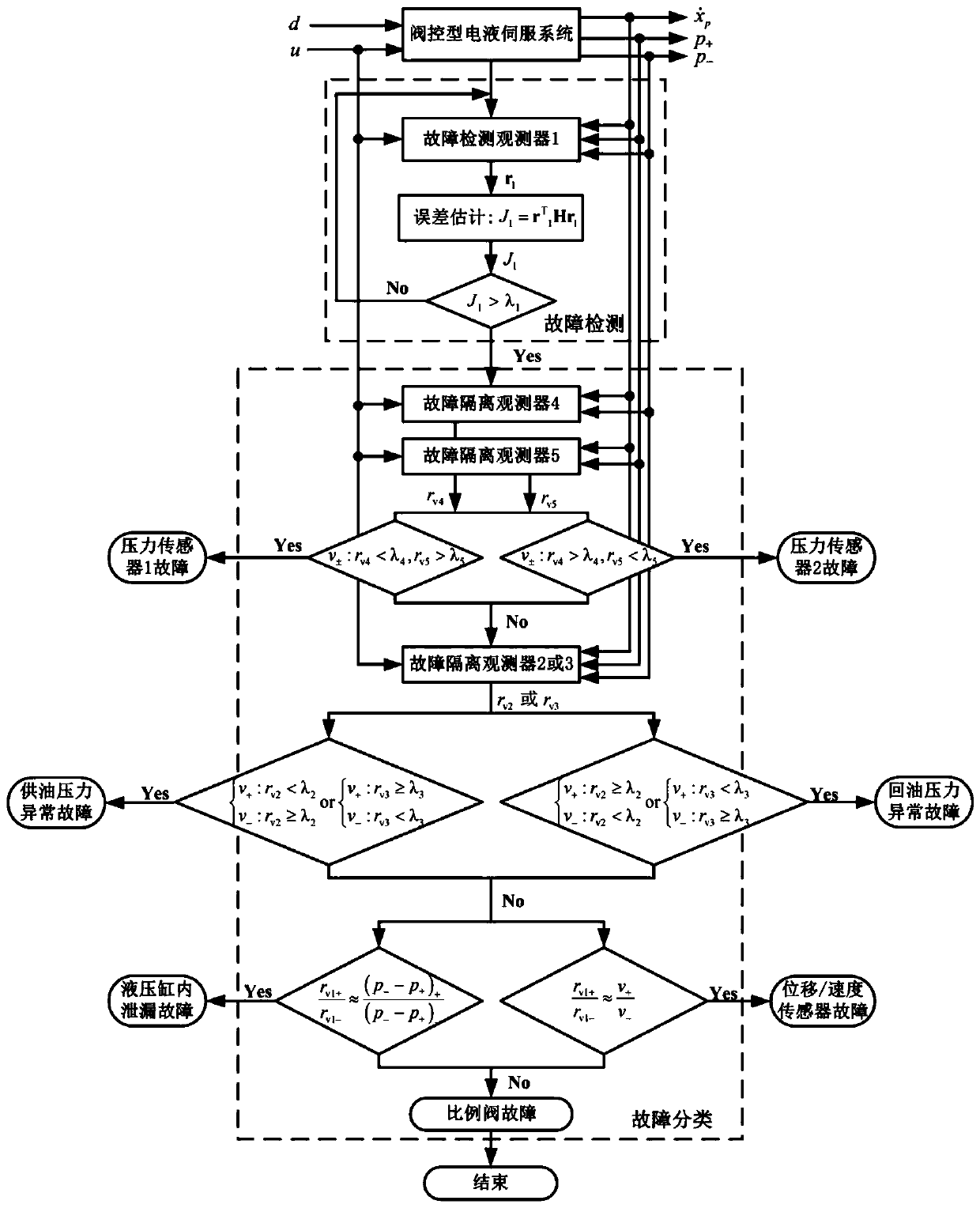

[0054] like Figure 1-3 As shown, the valve-controlled electro-hydraulic servo system fault detection and classification method based on the observer group, firstly, nonlinear modeling of the valve-controlled electro-hydraulic servo system is carried out, and the nonlinear state equation of the system is established by extracting four state variables . Then model seven common faults, including abnormal oil supply pressure, abnormal oil return pressure, internal leakage of hydraulic cylinder, servo valve / proportional valve, displacement sensor, and hydraulic cylinder inlet and outlet pressure sensor 1 and Pressure sensor 2 is faulty. According to the characteristics of each type of fault and the state space distribution, the system state equation is reorganized to form the corresponding state equation form. A nonlinear robust fault detection and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com