Device for removing residual toner of toner cartridge through backflow cleaning

A toner cartridge and cleaning technology, applied in electrography, optics, instruments, etc., can solve problems such as imperfect technical considerations, affecting printing quality, inhaling toner, etc., to reduce environmental pollution, improve cleaning effect, and ensure health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

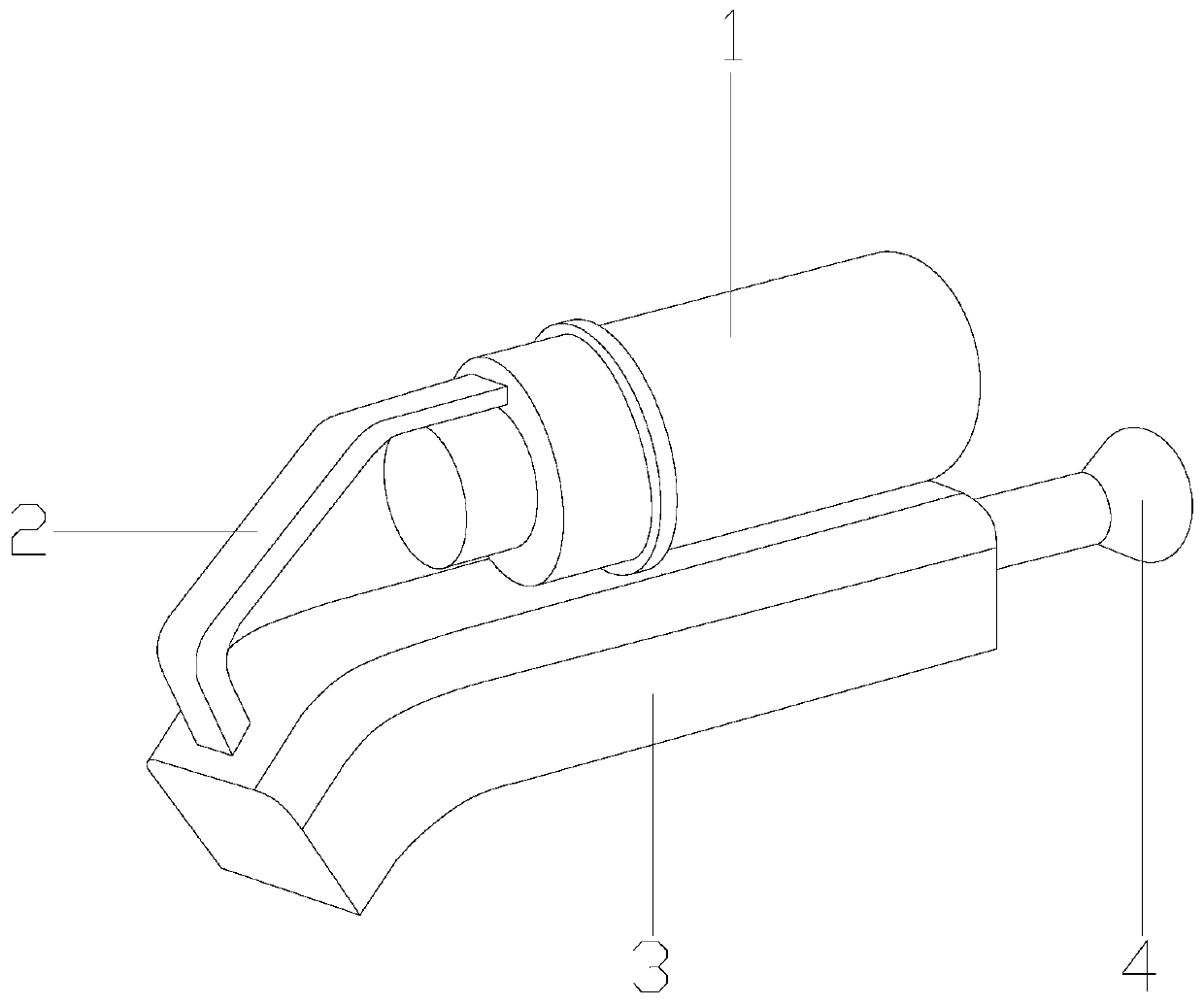

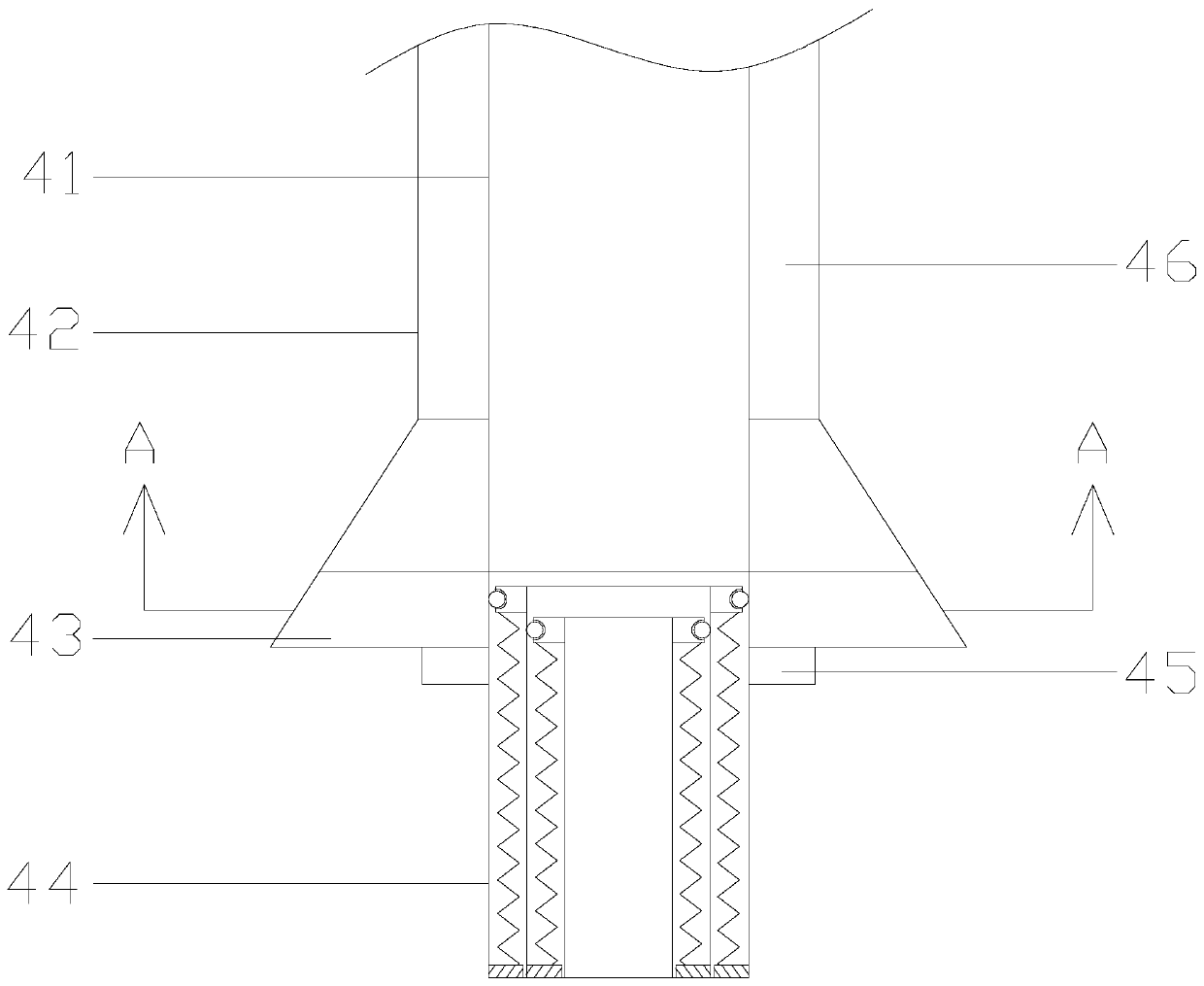

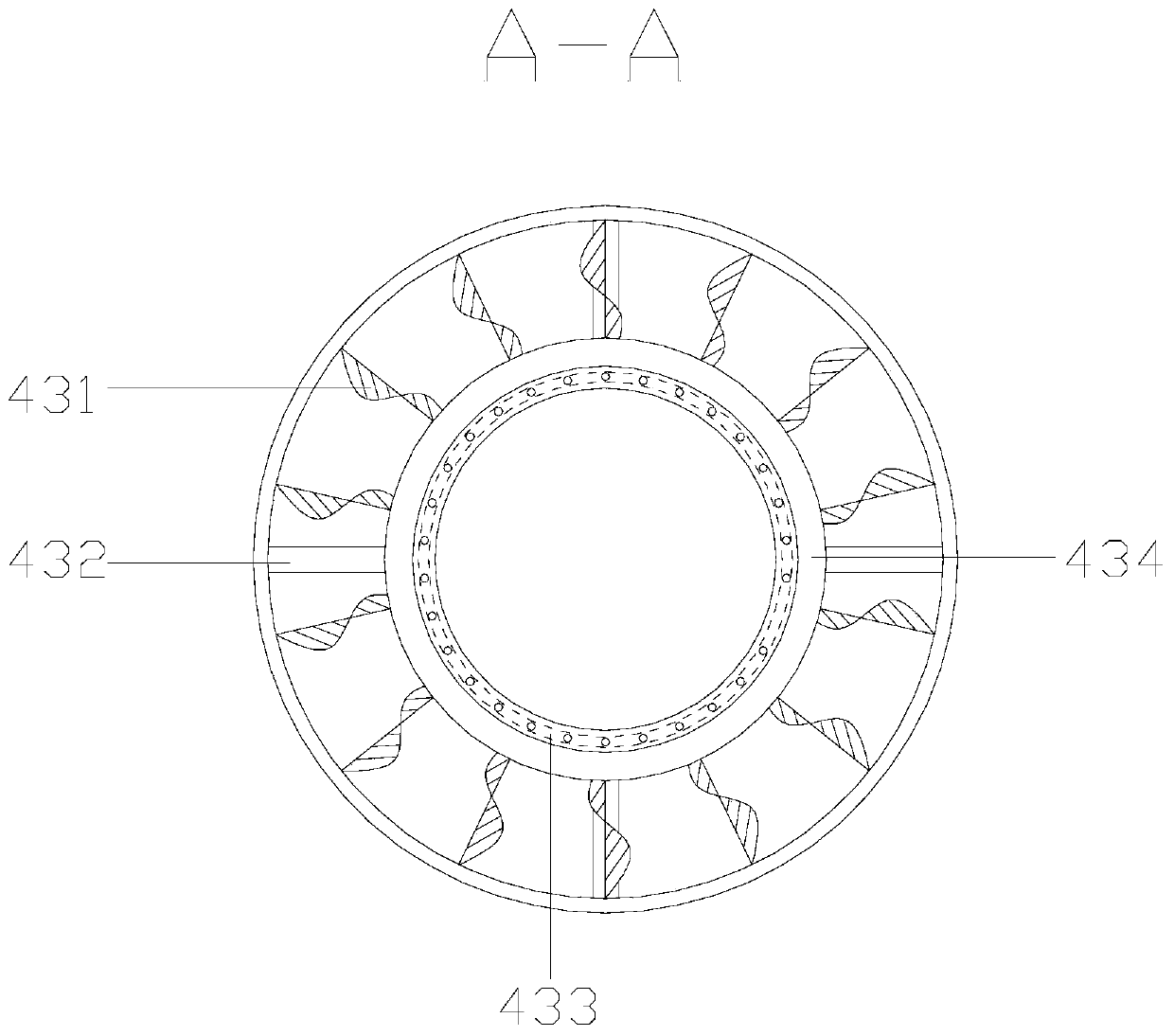

[0029] see Figure 1-Figure 2 , the present invention provides a toner cartridge residual powder removal device using backflow cleaning, its structure includes a toner collection box 1, an operating handle 2, a removal fan 3, a toner remover 4, the bottom of the operating handle 2 is connected to the removal The upper surface of the fan 3 is fixed together by bolts, the left end of the toner remover 4 is mechanically connected to the fan in the removal fan 3, the toner collection box 1 is a cylindrical structure and the left end is connected to the right end of the operating handle 2, Described toner remover 4 is made up of blower duct 41, remover main body 42, air pipe driving structure 43, air blowing pipe 44, steering adjustment device 45, carbon powder recovery pipe 46, and the top of described remover main body 42 and the bottom of blower fan 3 Bolts are fixed together, and the blower blower of described blower duct 41 top and clear blower 3 interpenetrates, and described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com