Lifting supporting type elevator shaft formwork device and construction method

An elevator shaft and supporting technology, which is applied in the fields of formwork/formwork/work frame, formwork processing, and on-site preparation of building components, can solve the safety risk of workers falling from drilling holes, damage to the support strength of the wall, and lack of Protection and other issues, to avoid the risk of falling objects, shorten the construction period, efficient and labor-saving and easy demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

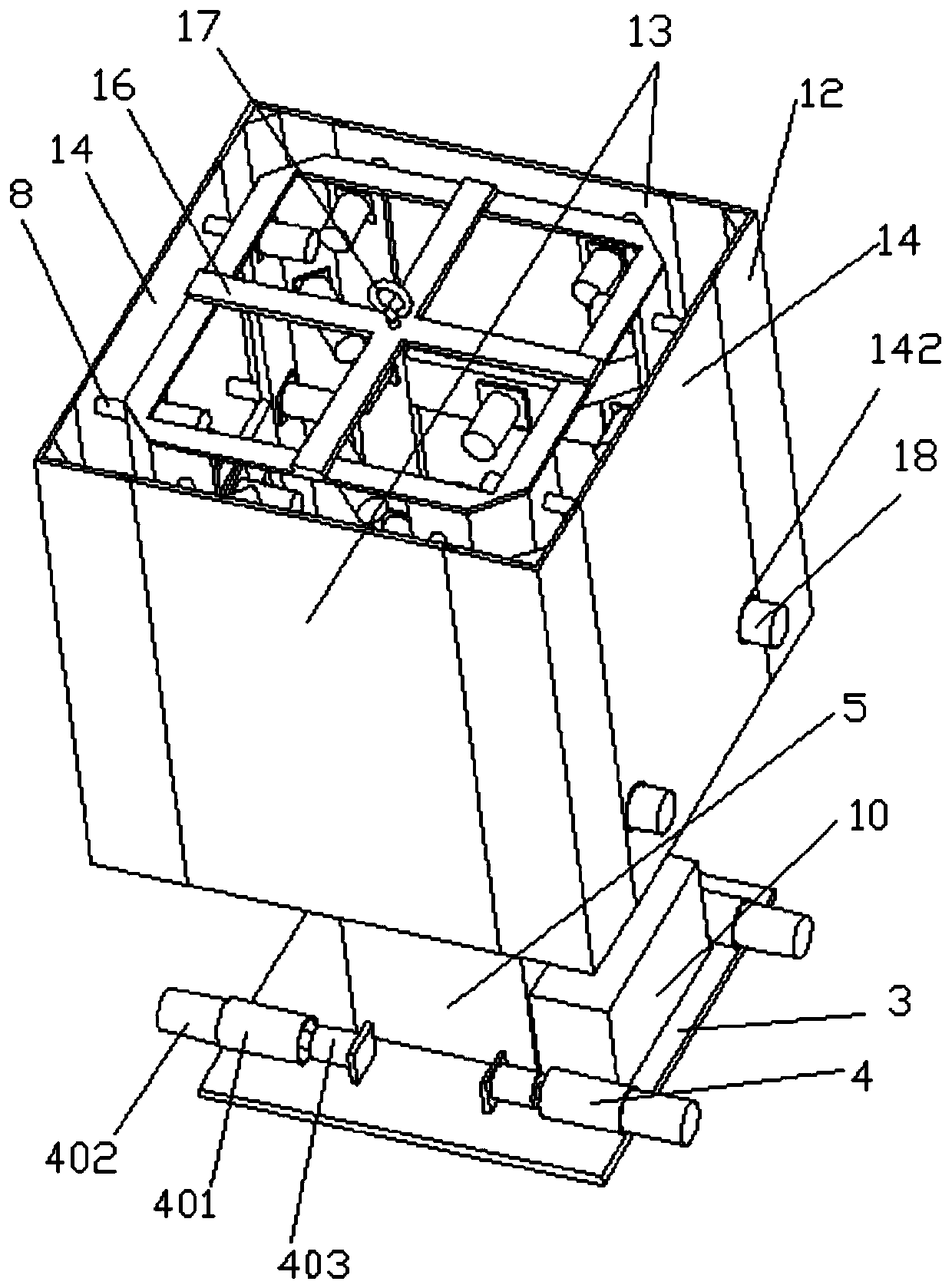

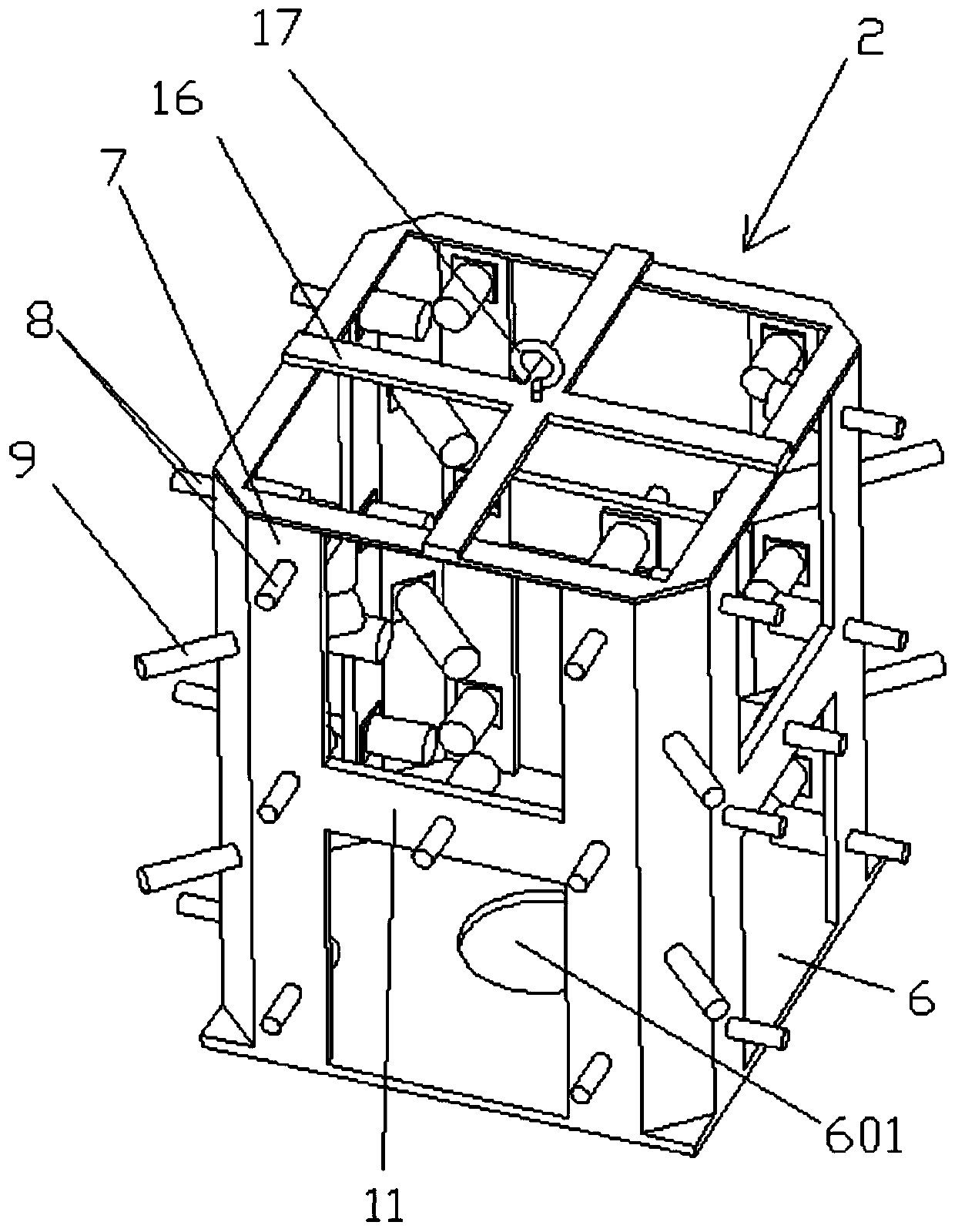

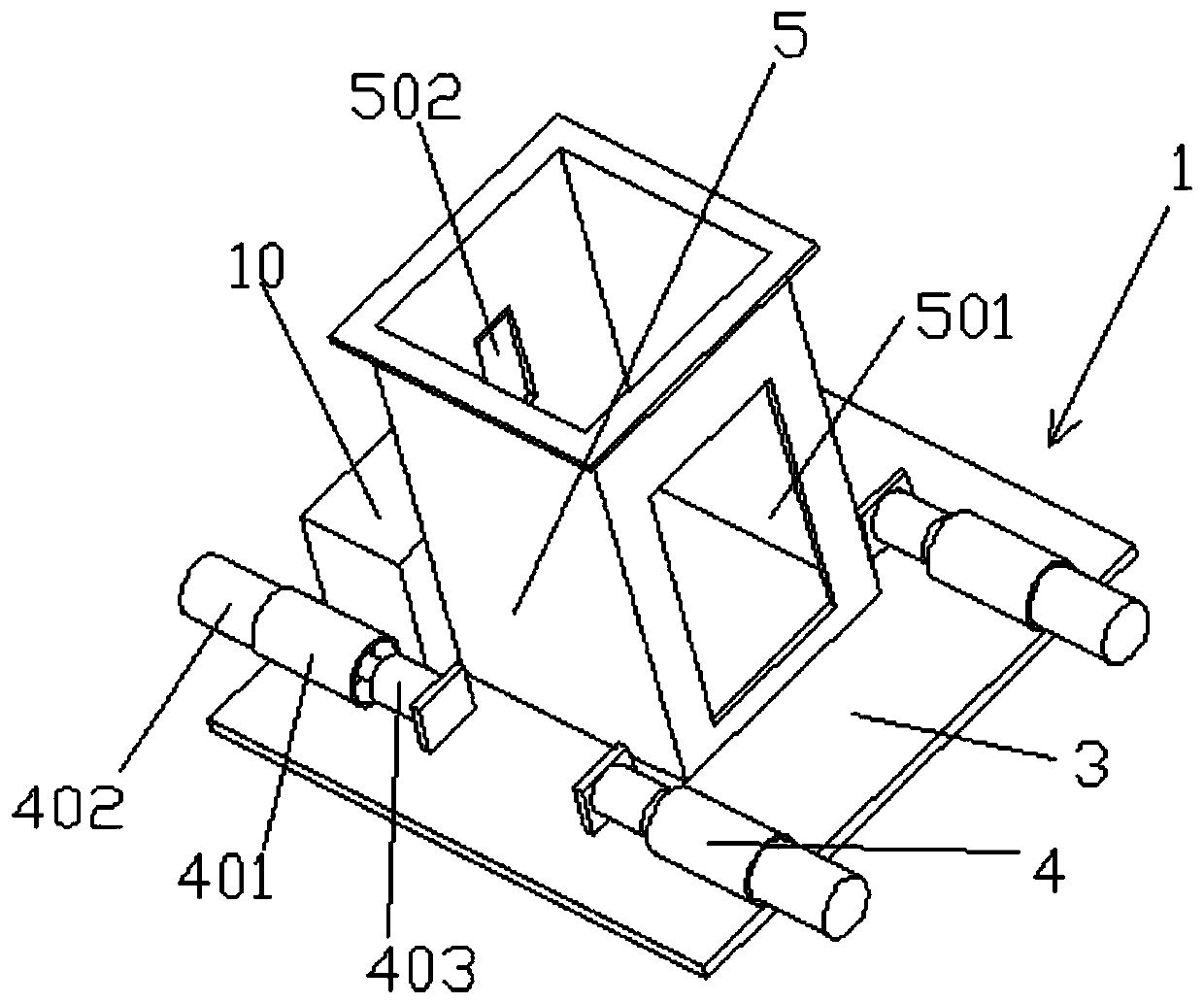

[0033] Attached below Figure 1-7 Specific examples of the present invention are described.

[0034] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The hoisting methods and the construction of the formwork outside the well in the following embodiments are all conventional hoisting methods and construction methods without special instructions. The names of parts and parts materials used in the following examples are commercially available unless otherwise specified. In the following embodiments, the realization of the control circuit where the control box is electrically connected to the hydraulic cylinder is a conventional control method unless otherwise specified; the connection between the hydraulic cylinder and the hydraulic circuit before the hydraulic station is a conventional hydraulic control method unless otherwise specified. Loop connection method.

[0035] In the present invention, unless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com