Tentering and shaping drying machine

A tenter setting and drying machine technology, which is applied to equipment for drying fabrics, heating/cooling fabrics, textiles and papermaking, etc., can solve the problems of low drying efficiency and poor drying effect, and achieves lower drying costs, lower distances, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

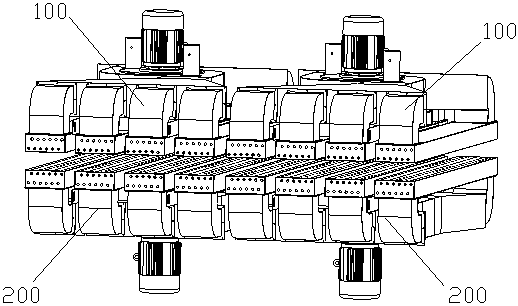

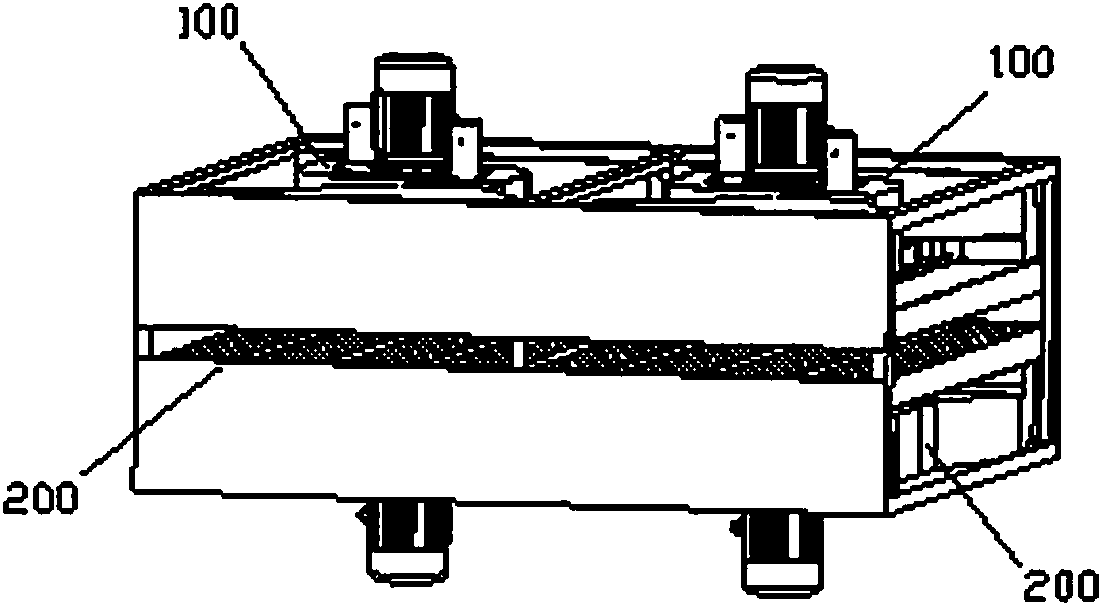

[0021] Such as Figure 1 to Figure 3 As shown, a tenter setting dryer includes one or more drying mechanisms, and the drying mechanism uses infrared light waves and hot air to dry and shape the fabric 300 to be dried and shaped.

[0022] Specifically, the drying mechanism includes an upper drying mechanism 100 and a lower drying mechanism 200 which are arranged symmetrically. The mechanism 100 dries and shapes the fabric 300 to be dried and shaped from top to bottom through infrared light waves and hot air, and the lower drying mechanism 200 dries and shapes the shaped fabric 300 to be dried and shaped from bottom to top through infrared light waves and hot air. By arranging two upper and lower drying mechanisms, the upper surface and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com