elevator safety system

A safety system and elevator technology, which is applied in the field of elevator control, can solve problems such as the inability of elevators to brake safely, and achieve the effects of reducing personnel injuries, facilitating troubleshooting, and reducing the number of contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

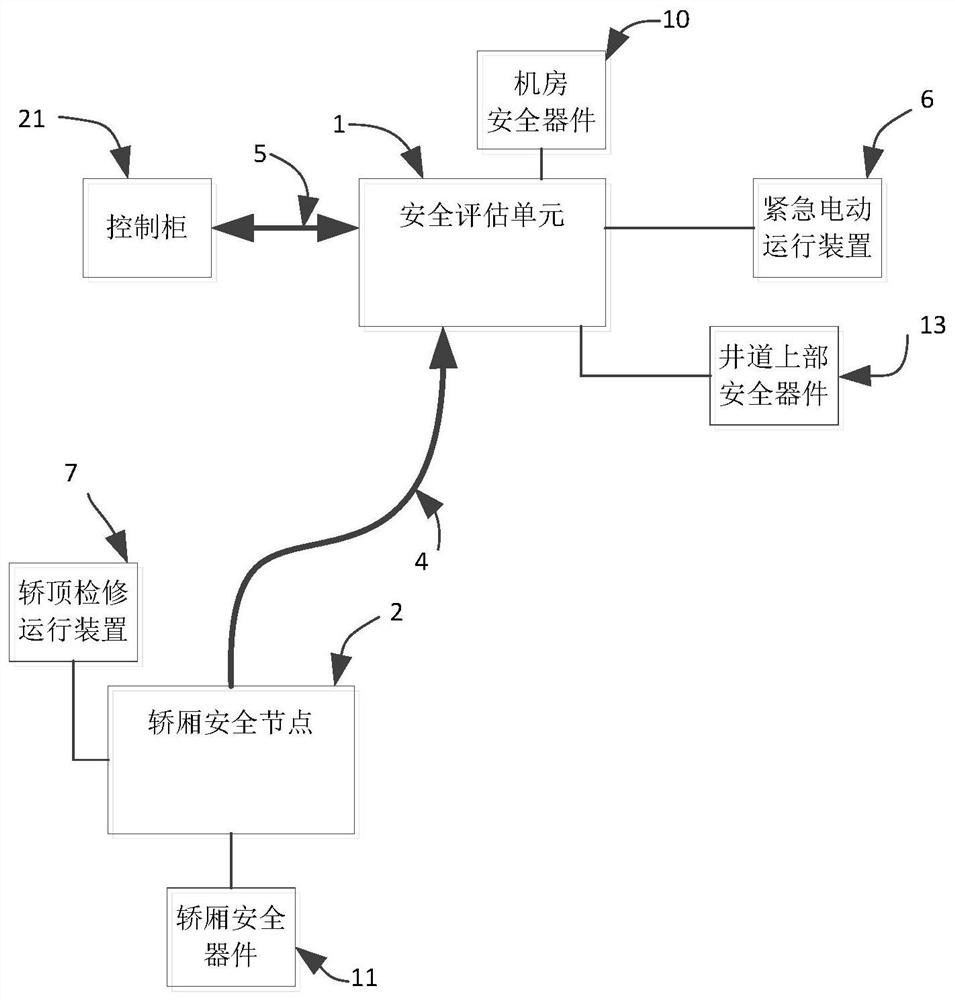

[0059] Such as figure 1 As shown, the elevator safety system includes a safety evaluation unit 1, a first serial bus 4, a car safety node 2, an emergency electric running device 6 and a car top maintenance running device 7;

[0060] The safety evaluation unit 1 communicates with the car safety node 2 through the first serial bus 4, communicates with the control cabinet 21 through the second serial bus 5, and connects the emergency electric running device 6 through the wiring harness;

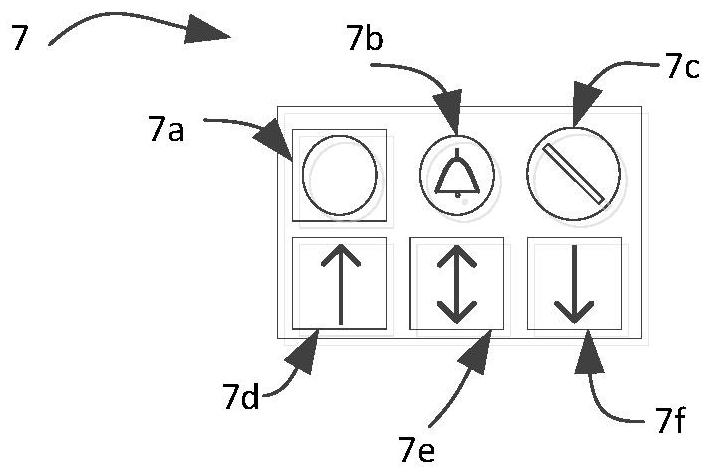

[0061] The car safety node 2 is connected to the car top inspection and running device 7 through a wiring harness;

[0062] The car safety node 2 receives the car top inspection operation function signal, the car top inspection uplink confirmation signal and the car top inspection downlink confirmation signal from the car top inspection operation device 7, and sends them to the security system via the first serial bus 4. Assessment unit 1;

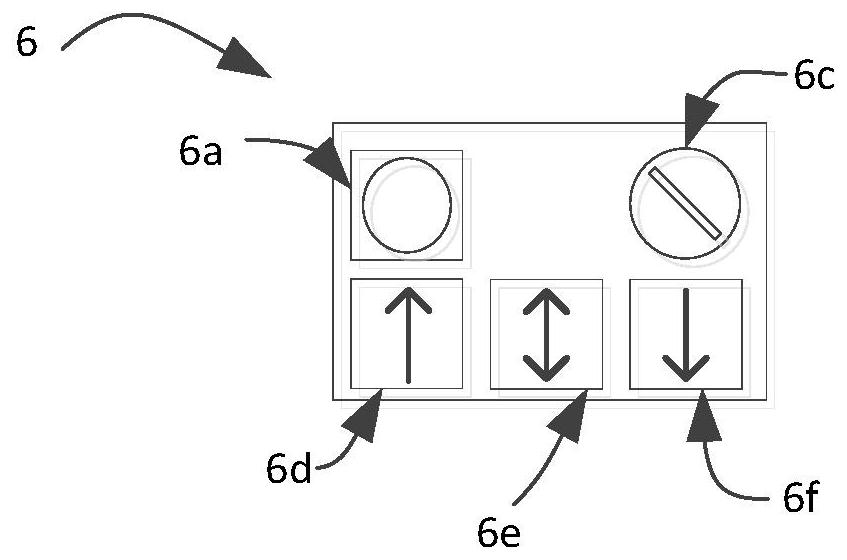

[0063] The emergency electric running device 6 is co...

Embodiment 2

[0076] Based on Example 1, such as image 3 As shown, the elevator safety system also includes a machine room safety device 10 and a hoistway upper safety device 13;

[0077] The safety evaluation unit 1 is respectively connected to the safety device 10 in the machine room and the safety device 13 in the upper part of the hoistway through the wiring harness.

[0078] Preferably, the safety evaluation unit 1 is based on the emergency electric running function signal from the emergency electric running device 6, the emergency electric running upward confirmation signal and the emergency electric running downward confirmation signal, and the car top inspection signal from the car safety node 2. The operation function signal, the upward confirmation signal of the car top inspection and the downward confirmation signal of the car top inspection, as well as the status of the safety device 10 in the machine room and the status of the safety device 13 in the upper part of the hoistway...

Embodiment 3

[0080] Based on Example 1, such as Figure 5 , Figure 6 As shown, the elevator safety system also includes a pit safety node 3 and a pit maintenance operation device 9;

[0081] The safety evaluation unit 1 communicates with the pit safety node 3 through the first serial bus 4;

[0082] The pit safety node 3 is connected to the pit maintenance operating device 9 through a wiring harness;

[0083] The pit safety node 3 receives the pit maintenance operation function signal / , the pit maintenance uplink confirmation signal and the bottom pit maintenance downlink confirmation signal from the pit maintenance operation device 9, and sends it to Safety Assessment Unit 1.

[0084] Preferably, the safety evaluation unit 1 is based on the emergency electric running function signal from the emergency electric running device 6, the emergency electric running upward confirmation signal and the emergency electric running downward confirmation signal, and the car top inspection signal f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com