Line-merging control mechanism

A technology of control mechanism and merging line, which is applied in the field of hanging conveyor lines, can solve problems such as low merging efficiency and failure to meet the fast and efficient merging requirements of vehicles, and achieve the effect of reducing drive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

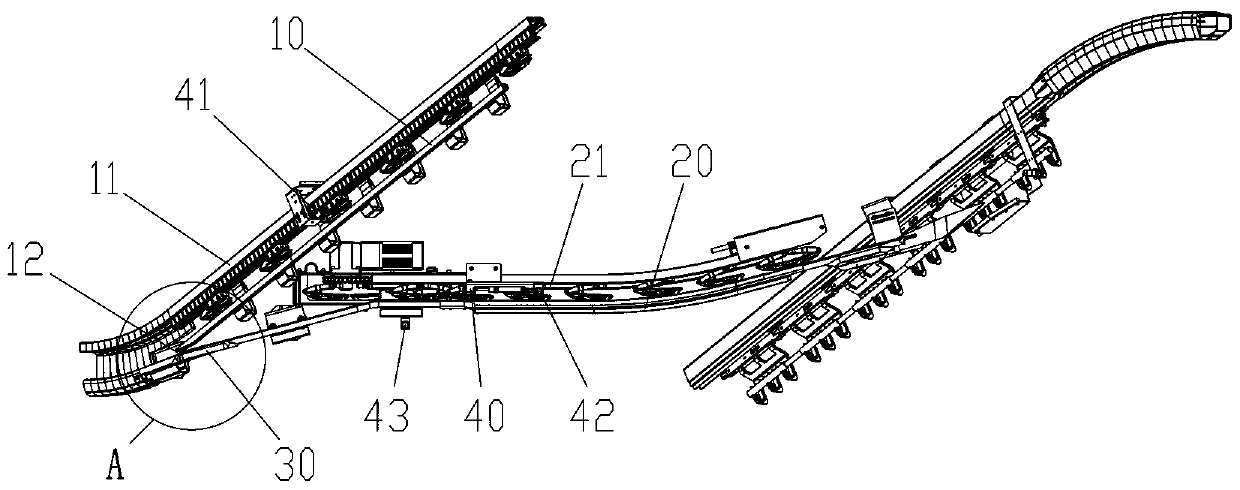

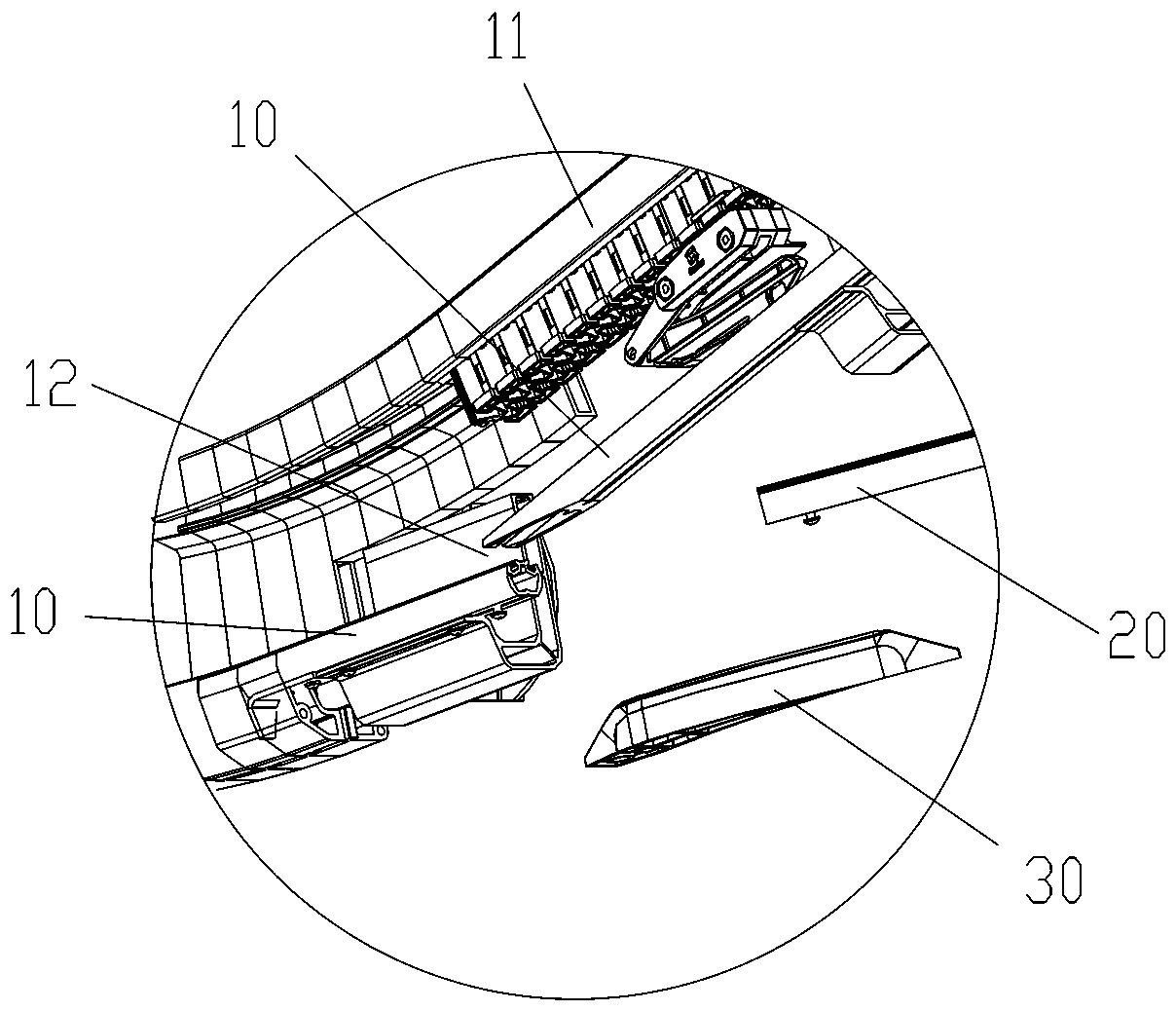

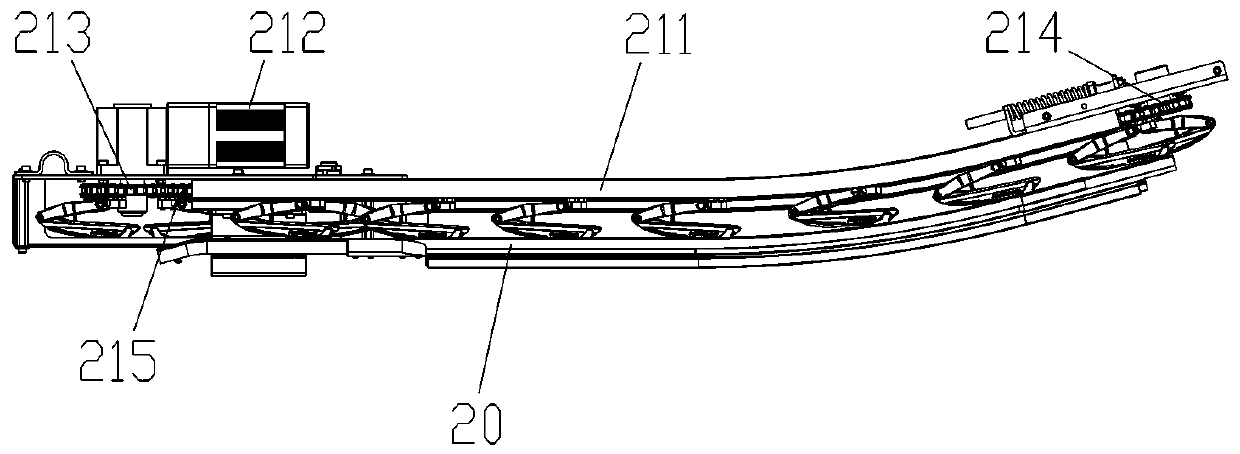

[0023] see Figure 1-4 , a confluence mechanism for a tow hook line, comprising a tow hook line main rail 10 and a merge line branch rail 20, a tow hook drive line 11 is arranged above the tow hook line main rail 10, and the structure of the tow hook drive line 11 can be Refer to the patent No.: 201821467974.0 for a confluence mechanism disclosed, which includes a drive track and a rack assembly installed on the drive track, a corresponding tow hook is installed under the rack assembly, and the tow hook driving line drives several tow hooks along the The main rail 10 of the tow hook line runs. For the structure of the tow hook, please refer to a suspension system chain drive assembly disclosed in Patent No. 201821133140.6. This tow hook is a one-way single-drag structure. When this When the front end of the tow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com